Spinning machine maintenance control equipment and control method

A technology for maintaining equipment and controlling equipment, applied to spinning machines, open-end spinning machines, continuous winding spinning machines, etc. Yarn position and other issues, to achieve the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In addition to the advantages already mentioned above with respect to the invention, further advantages are given in the following examples and figures.

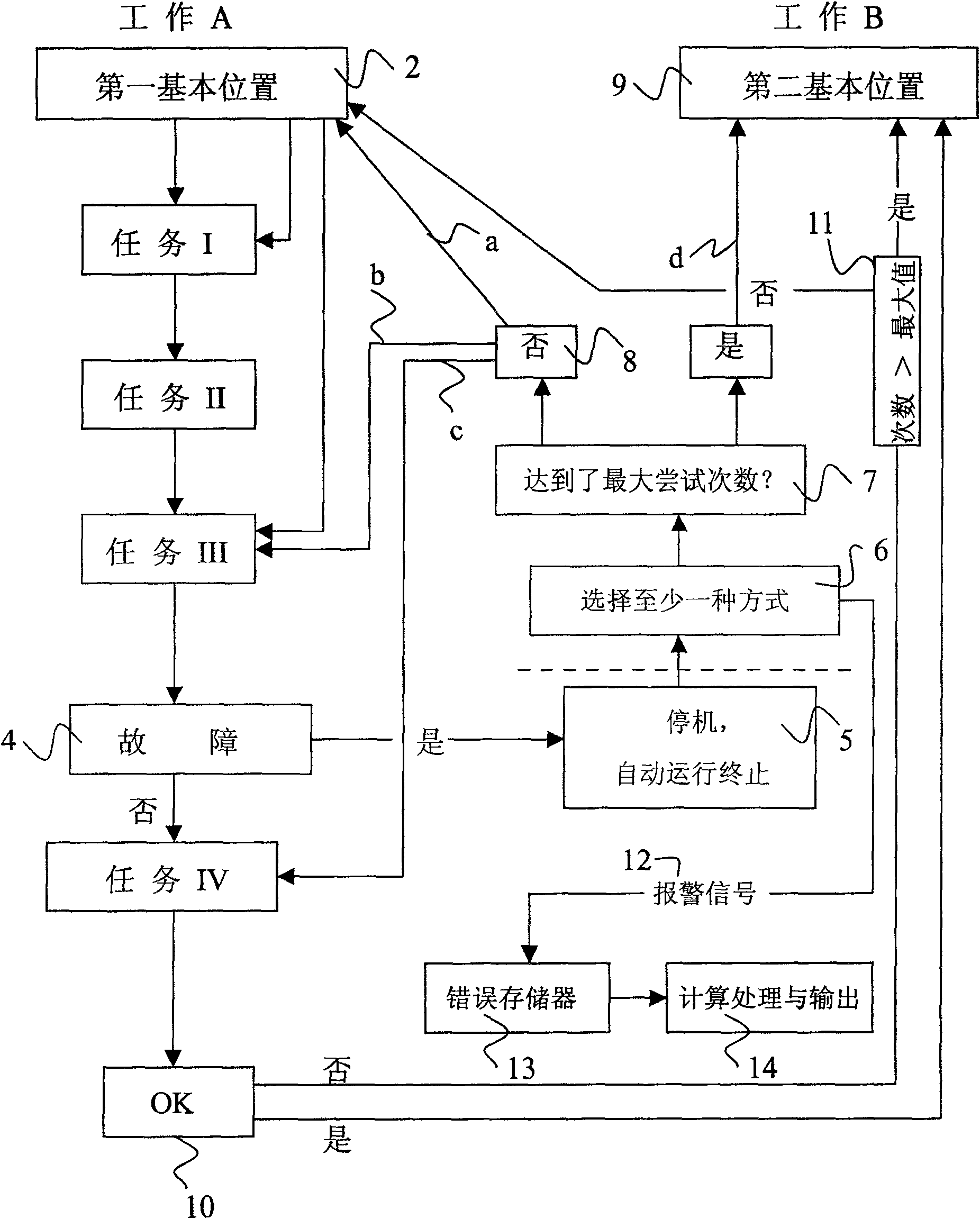

[0030] exist figure 1 A schematic flow diagram of the method of the present invention is given in . Devices that perform maintenance work on the spinning frame, such as maintenance equipment or maintenance robots, shall perform a defined task A on the spinning frame. This job A that needs to be done starts from the basic position 2. To this end, it is necessary to complete a series of tasks that link up and down. Here, they are the four tasks I to IV. In the example given, failure 4 occurred between mission III and mission IV. As an example, fault 4 can be that the manipulator of the maintenance device has not returned to the specified end position. The control unit mounted on the maintenance unit detects this fault because, for example, the end position switch does not give a corresponding signal. In this case,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com