V cone type coupling seat of absorbing shock utilized in agitating plug flow equipment

A coupling seat and cone-type technology, applied in the field of V-cone vibration-absorbing coupling seat, can solve the problems of increased cost, reduced performance, and fragile equipment, and achieves the effects of resisting shock loads, stable and reliable work, and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

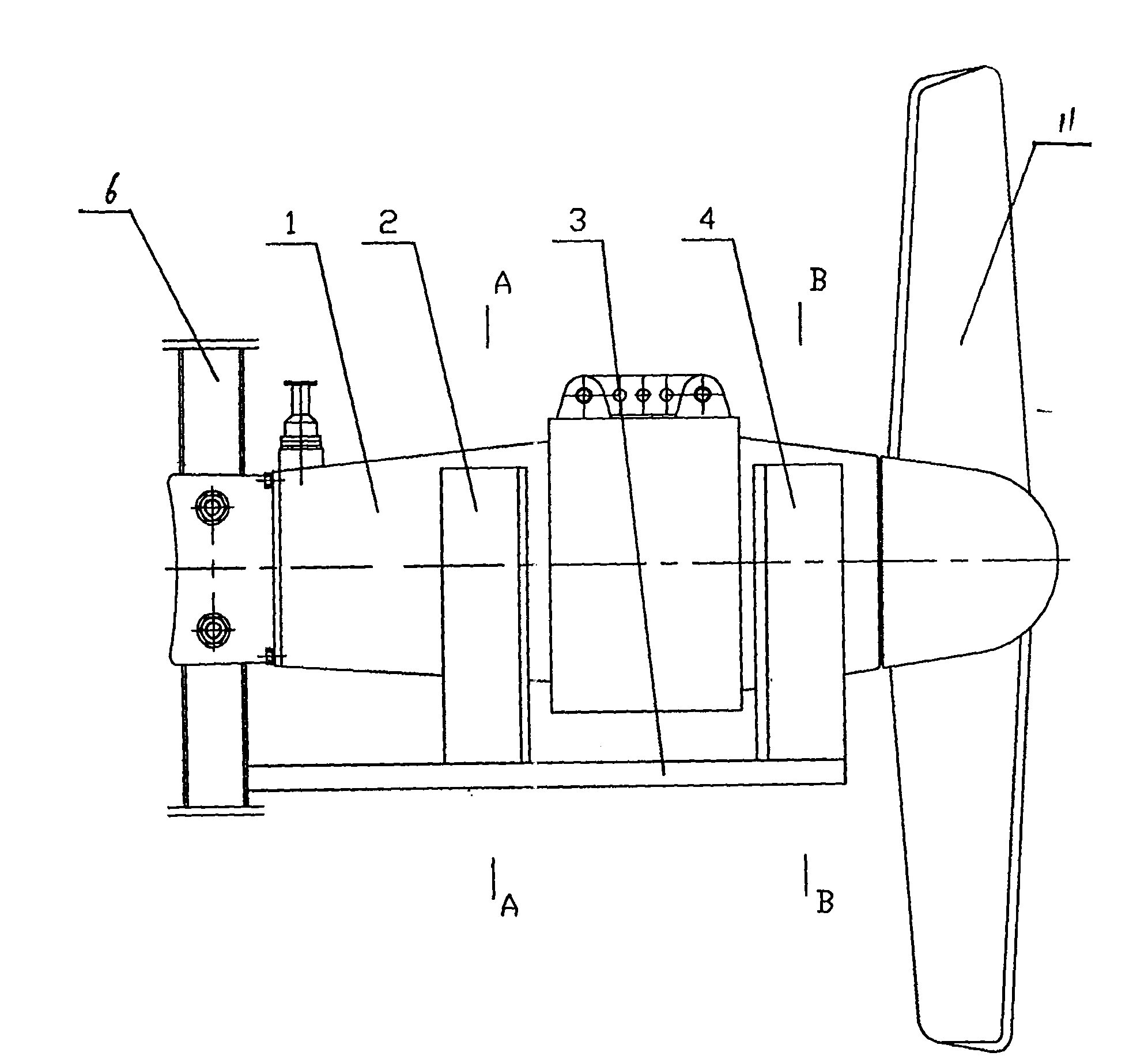

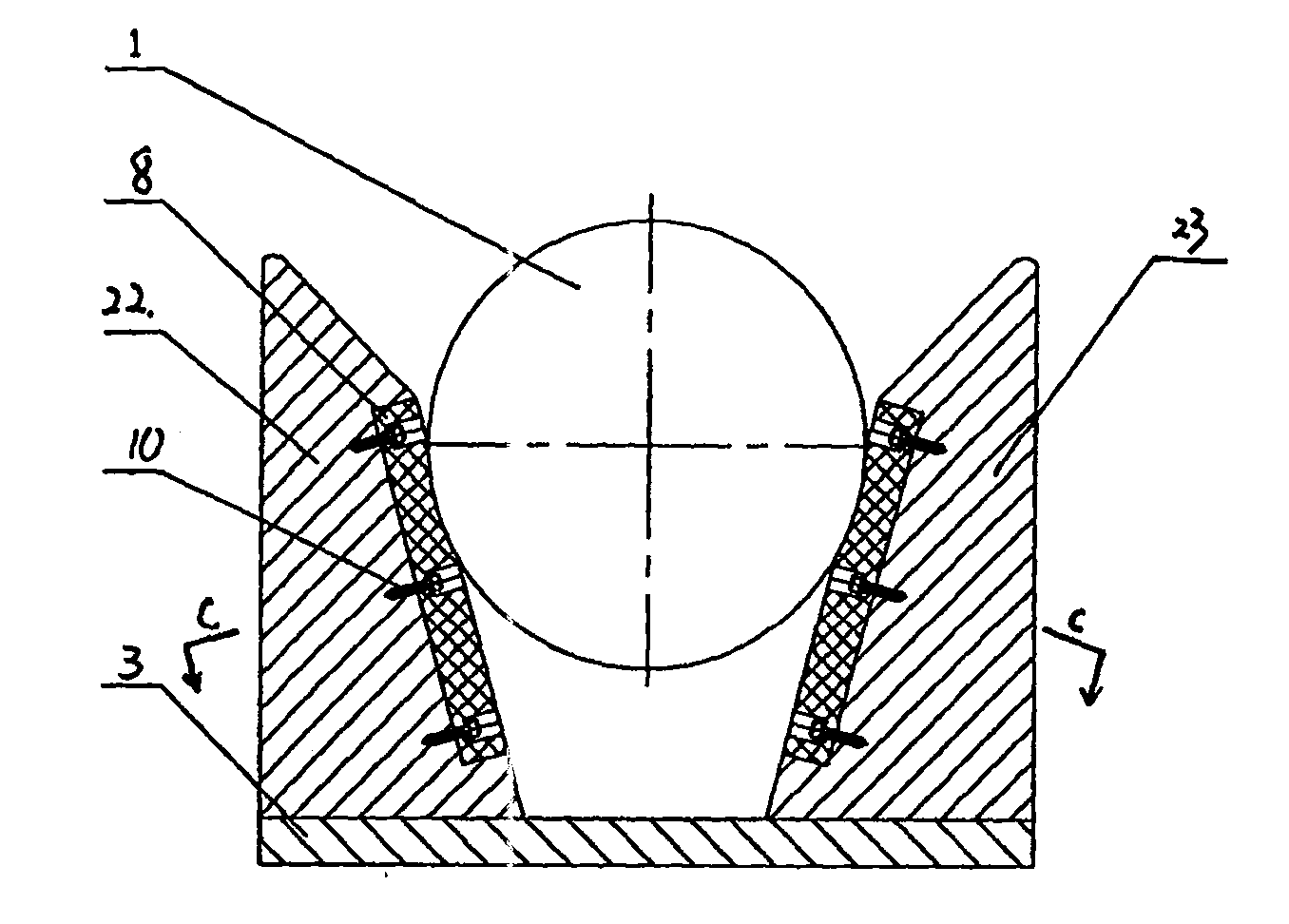

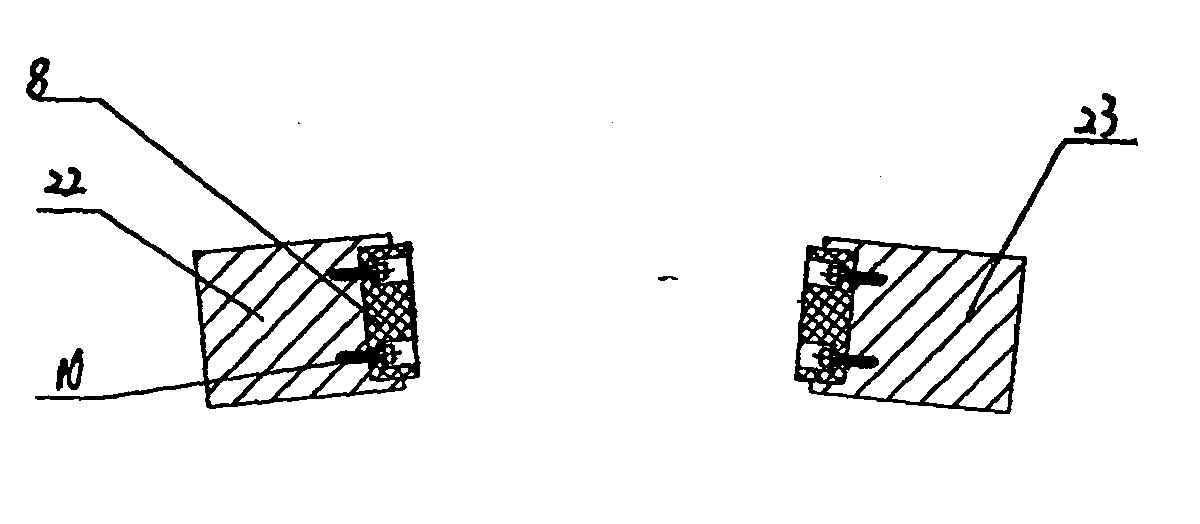

[0020] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 and Figure 13 Among them, the present invention is a V-cone vibration-absorbing coupling seat for stirring and pushing equipment, which is composed of a left frame body 2, a coupling bottom frame 3 and a right frame body 4, and the left frame body 2 and the right frame body 4 are fixed on the coupling On the bottom frame 3, a space is provided between the left frame body 2 and the right frame body 4, and the longitudinal arrangement structure of the two support blocks 22, 23 of the left frame body 2 and the two support blocks 42, 43 of the right frame body 4 is set. Cone mouth shape, the two support blocks 22, 23 of the left frame body 2 and the two support blocks 42, 43 of the right frame body 4 are vertically arranged to form a face-to-face cone mouth shape with a cone angle of 10°-15°. Or the middle of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com