Intograted moulding technology of mutual inductor

A technology combining transformer and molding process, applied in the direction of household components, household appliances, other household appliances, etc., can solve the problems of product scrap, easy degumming and water ingress, inaccurate product measurement, etc., to prevent surface flashover, simple and practical Benefit, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

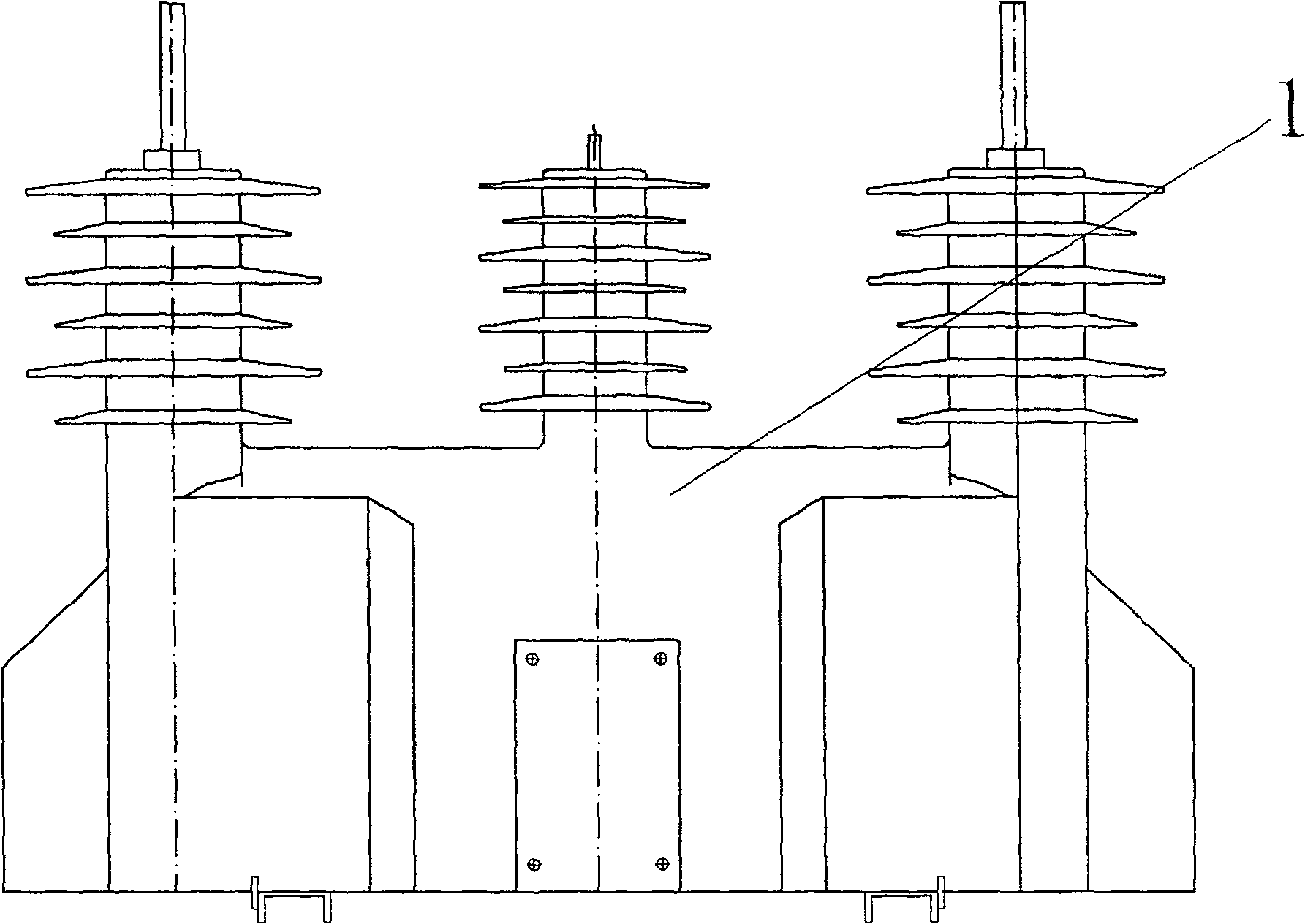

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

[0010] The integral molding process of this combined transformer mainly includes the following steps: After the inner casting body is poured, it enters a mold for one-time molding, and uses liquid two-component silicone rubber, which is injected into the mold cavity by liquid pressure to perform one-time molding. The inner casting body is encapsulated, heated and vulcanized to form a combined transformer; the raw material is two-component liquid silicone rubber with a hardness of 20 and 50 in the Dow Corning liquid silicone rubber LC 2004 series (LC 2004 series liquid silicone rubber is provided by 7 high-transparency formulas with different hardness ranges from 20 to 80, the present invention selects two of them, and the experimental data proves that the performance index is better after the liquid two-component silicone rubber with these two hardnesses is mixed in proporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com