Clutch for a transmission

A clutch and reaction plate technology, used in clutches, friction clutches, mechanical drive clutches, etc., can solve the problems of metal friction materials that are not cost-effective, low torque capacity, and low effectiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

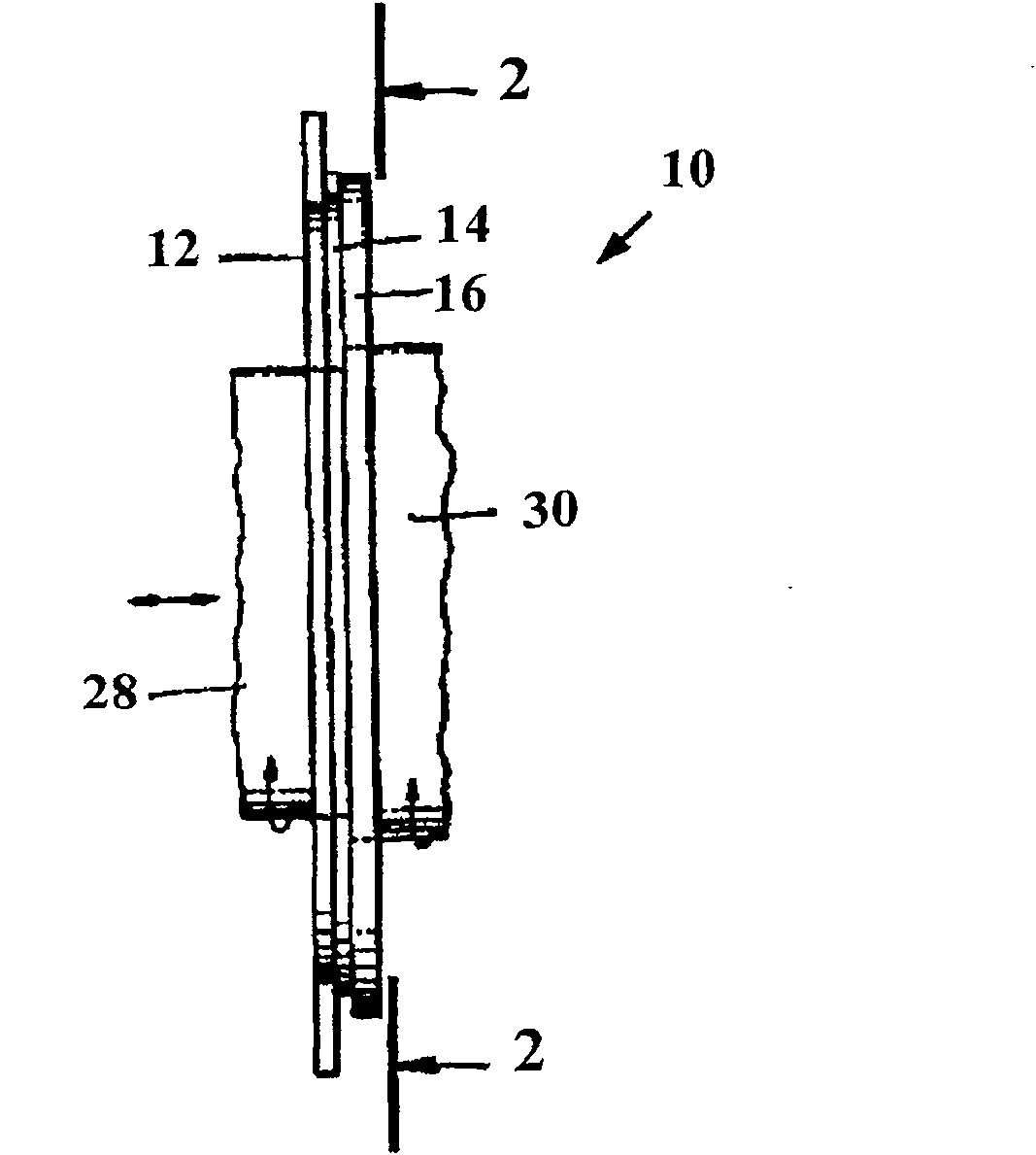

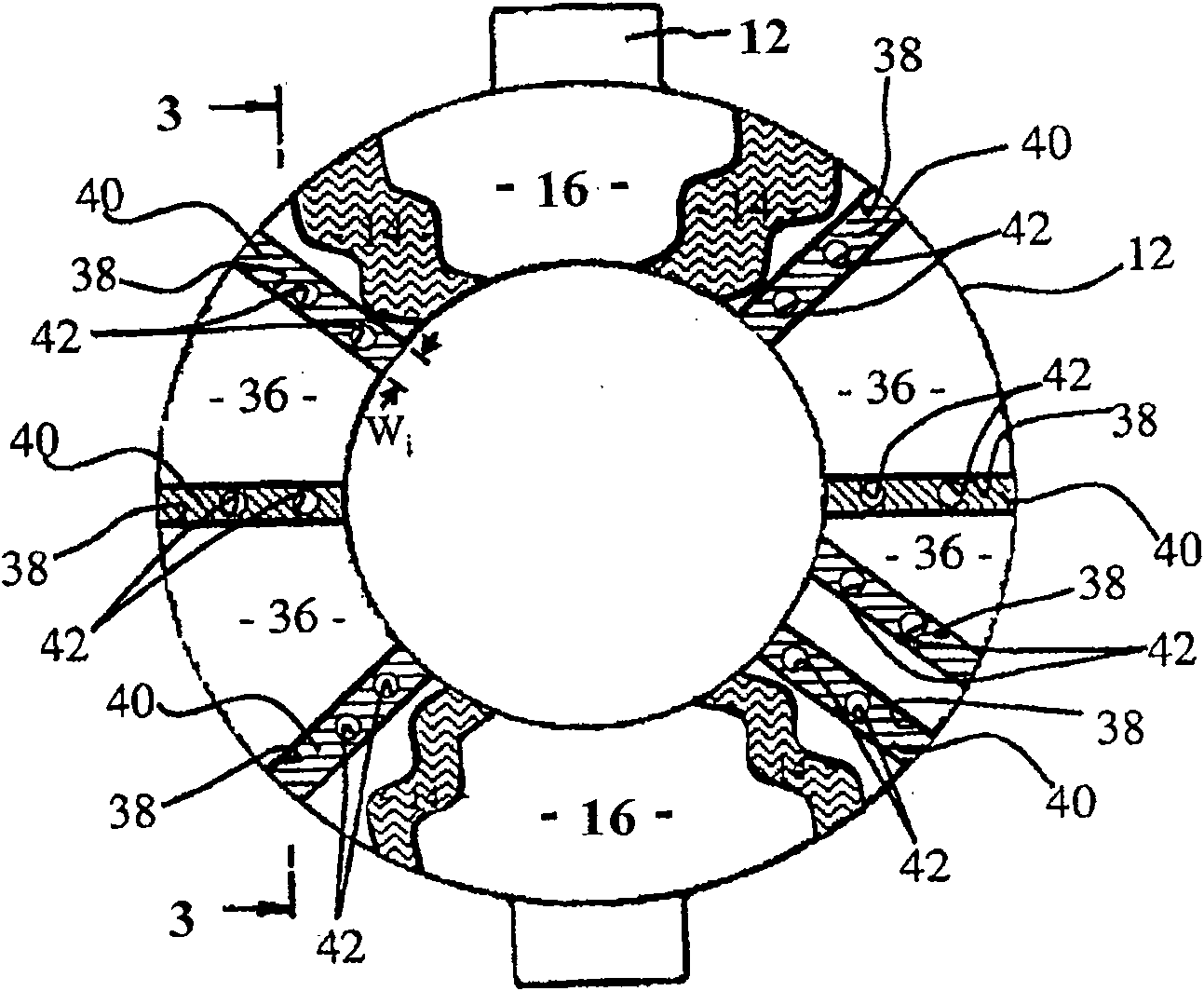

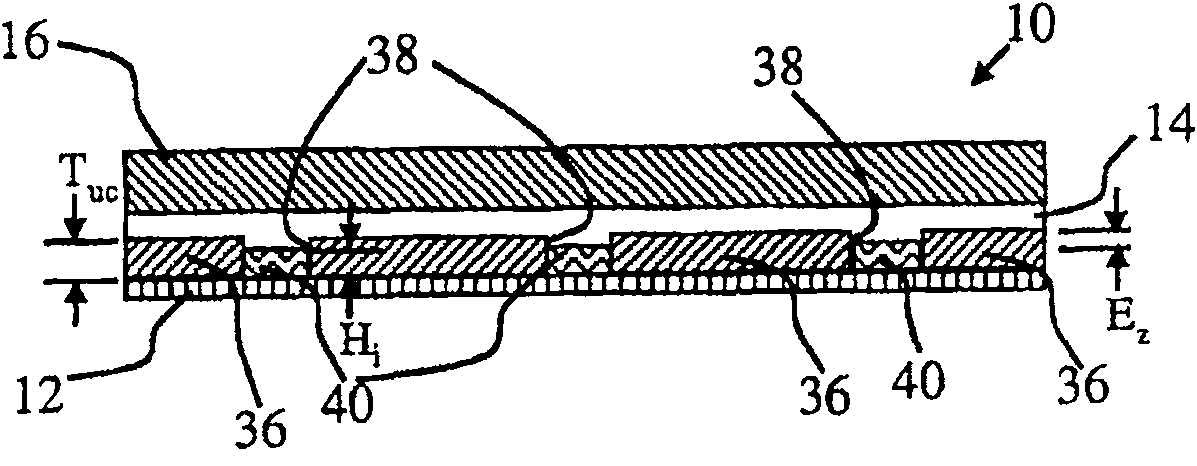

[0026] Referring to the drawings, like numerals refer to like components. figure 1 A side view of a torque transmitting device 10 according to one embodiment of the present invention is shown. Torque transmitting device 10 is commonly referred to in automotive applications as a clutch or brake. The device 10 has a first or friction plate 12 and a second or reaction plate 16 . Friction plate 12 is separated from reaction plate 16 by a layer of lubricating fluid 14 . A fluid lubricant 14 disposed between the reaction plate 16 and the friction plate 12 provides a lubricating layer between the plates. The torque transmitting device 10 is connected between the drive shaft 28 and the driven shaft 30 . More specifically, the friction plate 12 is coupled to the drive shaft 28 and the reaction plate 16 is coupled to the driven shaft 30 . Drive shaft 28 is typically coupled to a torque-generative device such as an internal combustion engine (not shown). The driven shaft 30 may be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com