A mechanically controllable cracking device and method for multi-level control electrode spacing continuously changing

A technology for controlling electrodes and spacing, which is applied in the field of molecular electronics, can solve the problems of low control precision, large jitter, and high cost, and achieve the effects of stable driving process, extended displacement length, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to understand the technical features, purpose and effect of the present invention more clearly, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

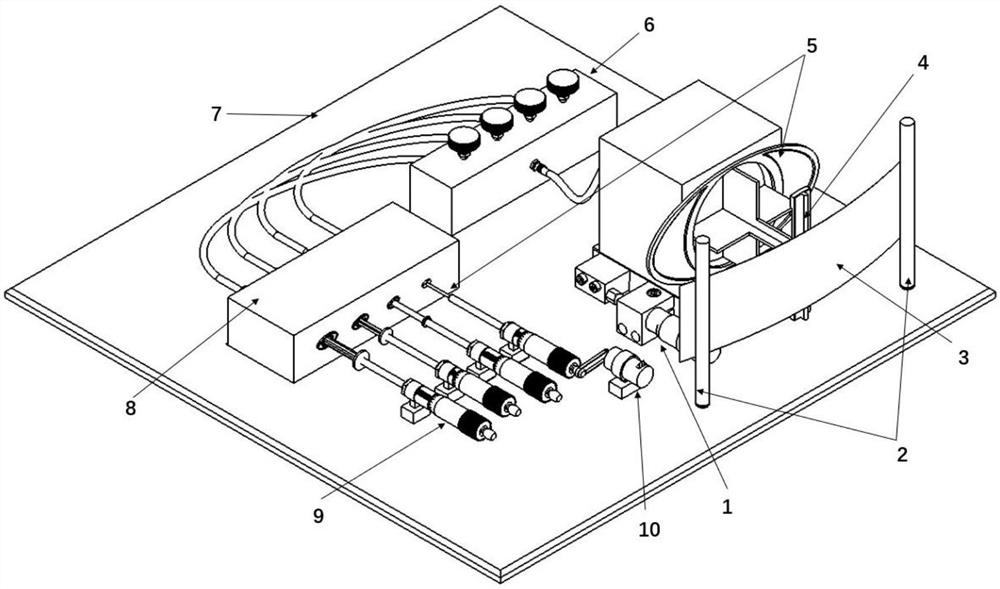

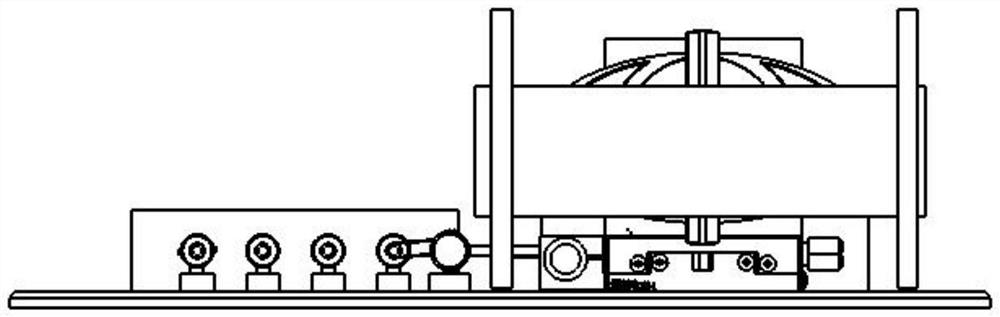

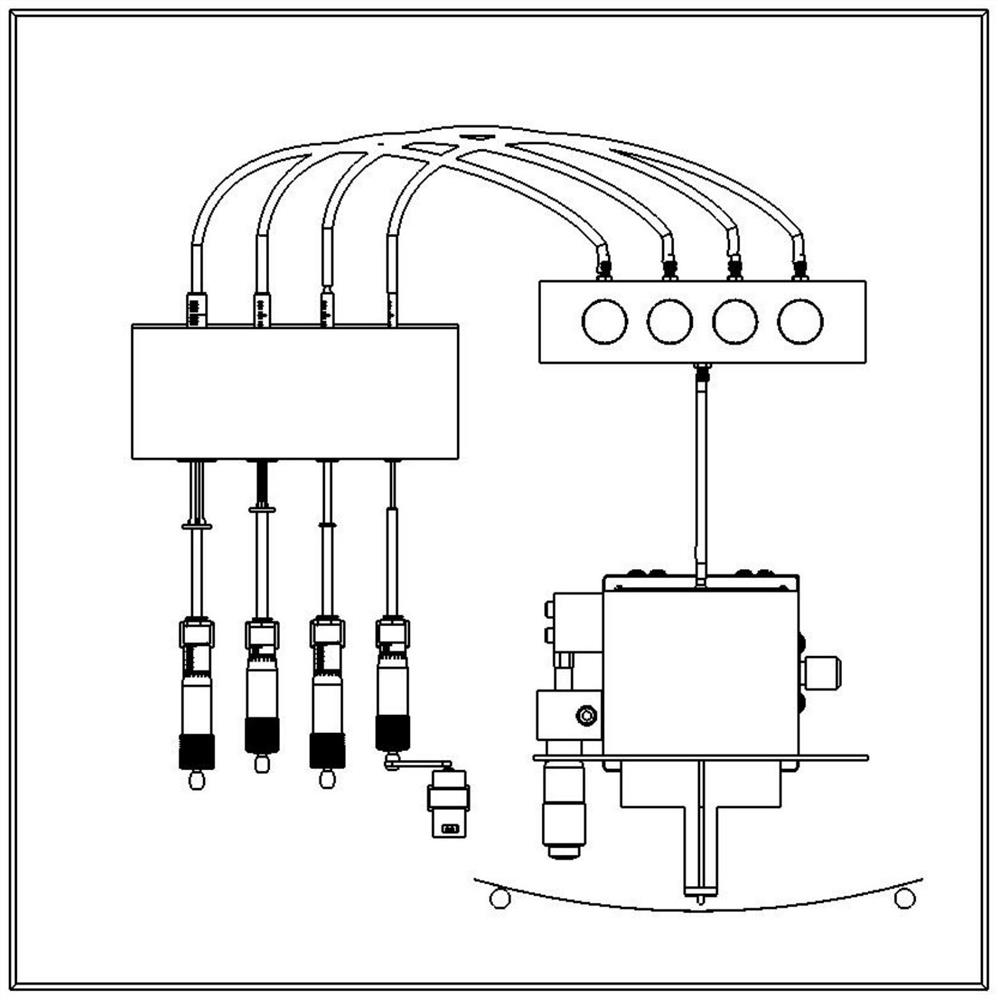

[0030] Such as Figure 1~5 As shown, the sub-femto-level mechanical controllable cracking device based on hydraulic principle multi-level control, the device includes X-axis linear displacement table 1, support rod 2, steel sheet 3, piston push rod 4, hydraulic cylinder 5, hydraulic valve 6. Base 7, bracket 8, screw push rod 9, motor 10. There are 4 screw push rods 9, including a 10mm inner diameter screw push rod 91, a 7.5mm inner diameter screw push rod 92, a 5mm inner diameter screw push rod 93, and a 2.5mm inner diameter screw push rod 94.

[0031] The base 7 of the present invention is square, and other components are located above the base 7. The inside of the hydraulic cylinder 5, the hydraulic valve 6 and the connected pipelines a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com