Compensation method and apparatus for a Coriolis flow meter

A flow meter and flow technology, applied in direct mass flow meter, mass flow measurement device, liquid/fluid solid measurement, etc., can solve the problems of inaccuracy, inaccurate temperature compensation flow velocity output signal, time difference of temperature change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0134] the term

[0135] FCF Current Technology Flow Calibration Factor

[0136] α current technology FCF temperature coefficient

[0137] The Δt flow causes a time delay

[0138] Δt 0 Nominal time delay for zero flow

[0139] mass flow rate

[0140] F Operating drive frequency

[0141] f 0 Manufacturer's choice of rated drive frequency (under typical thermal conditions)

[0142] ZERO(F) describes the effect frequency without nominal time delay, Δt 0 equal to Δt 0+ (F-F 0 )α F

[0143] alpha F Linear frequency constant for zero

[0144] alpha m Proportionality factor relating Δt to mass flow. Similar to FCF in current technology.

[0145] alpha mF alpha m The linear frequency (temporary) coefficients of . Similar to alpha in current technology.

[0146] FMUT Flowmeter under test.

[0147] figure 1 description of

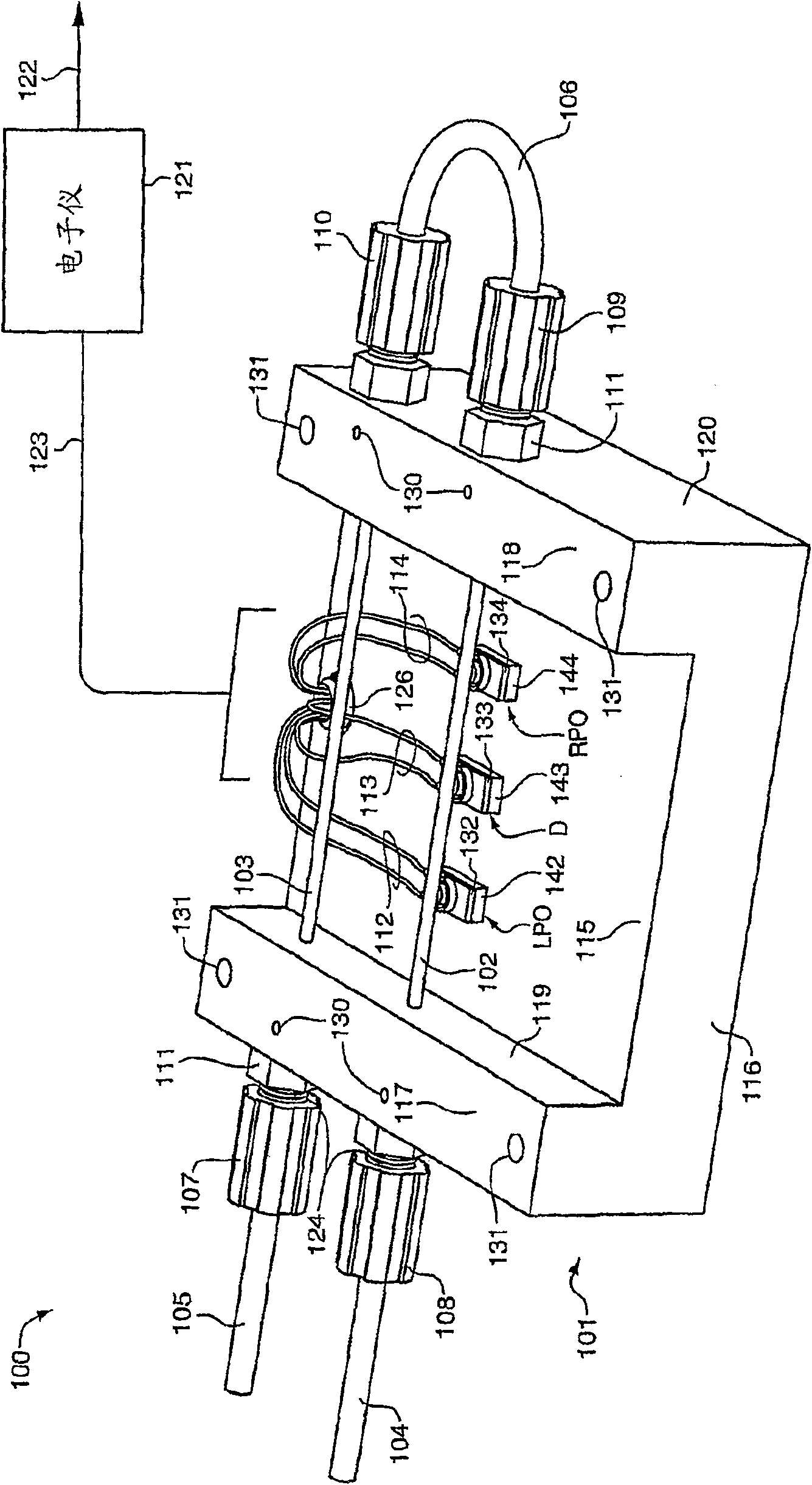

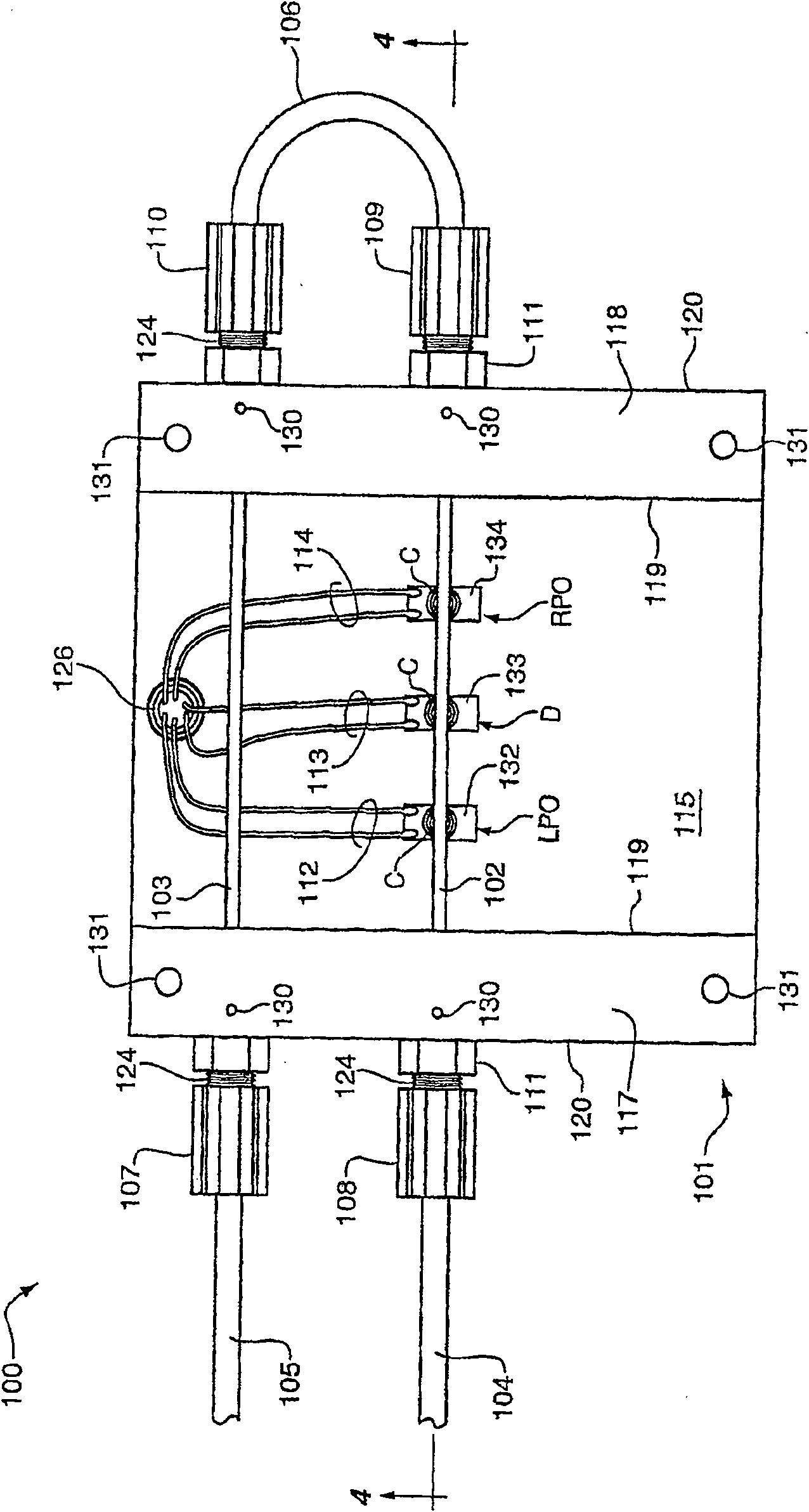

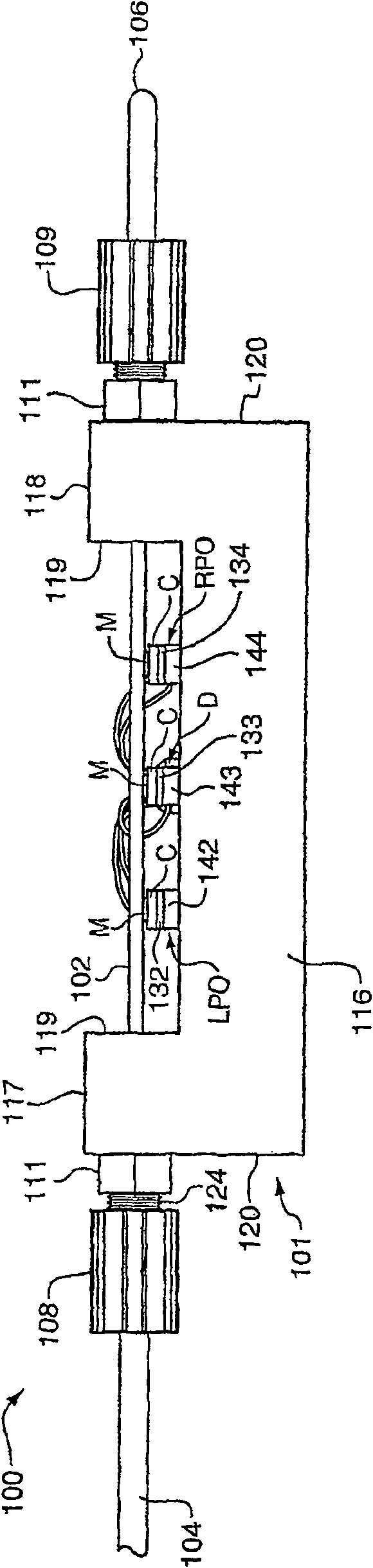

[0148] figure 1 is a perspective view of a first possible exemplary embodiment of a Coriolis flow meter embodying the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com