A method of pre-treatment and components separation of waste lead-acid accumulator

A technology of lead-acid batteries and waste batteries, which is applied in the field of lead smelting, can solve the problems of serious waste acid pollution, poor environment, and low investment, and achieve the effects of high metal recovery rate, avoiding air pollution, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

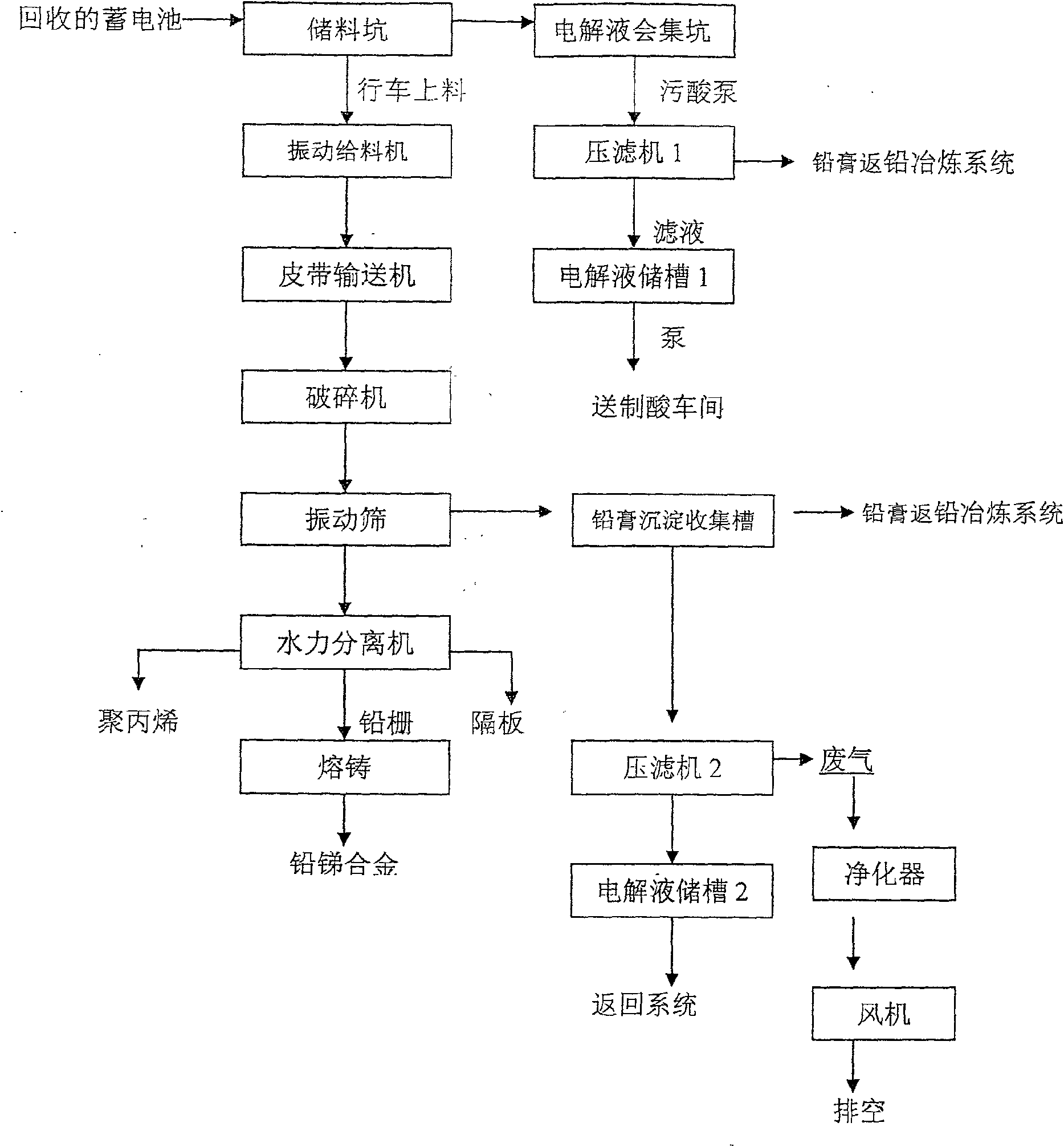

[0030] As shown in the figure, the specific steps are as follows:

[0031] (1) Break the waste battery in the storage pit so that the waste electrolyte can flow to the storage pit by itself;

[0032] (2) Send the broken waste battery to the hopper of the vibrating feeder, and then convey it to the crusher by the conveyor belt. The magnetic metal and iron fragments in the waste are detected by the magnetic separation equipment installed on the conveyor belt It is screened and separated to protect the crusher after being crushed by the crusher to produce mixed crushed materials with the largest particle size not greater than 80MM, and the crushed materials directly enter the oscillating separator;

[0033] (3) After the pulverized material is separated by shaking, the slurry enters the sedimentation collection tank to concentrate the slurry into lead paste concentrated slurry; the large particulate matter left on the screen of the vibrating separator enters the hydrodynamic separato...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap