High-frequency apparatus

A technology for high-frequency equipment and front panels, applied to structural parts of electrical equipment, housings/cabinets/drawers of electrical equipment, electrical components, etc., can solve the problem of decreased density of wiring patterns 60, reduced area of circuit substrates 59, and increased Problems such as large circuit substrates, to achieve the effect of increasing density, shortening length, and increasing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

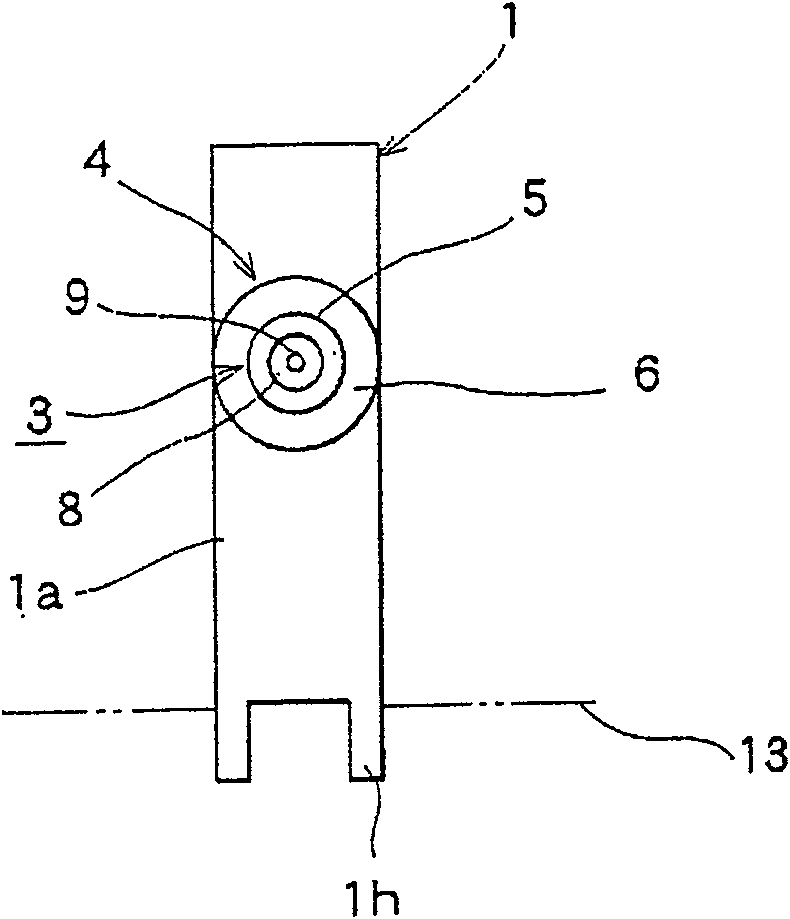

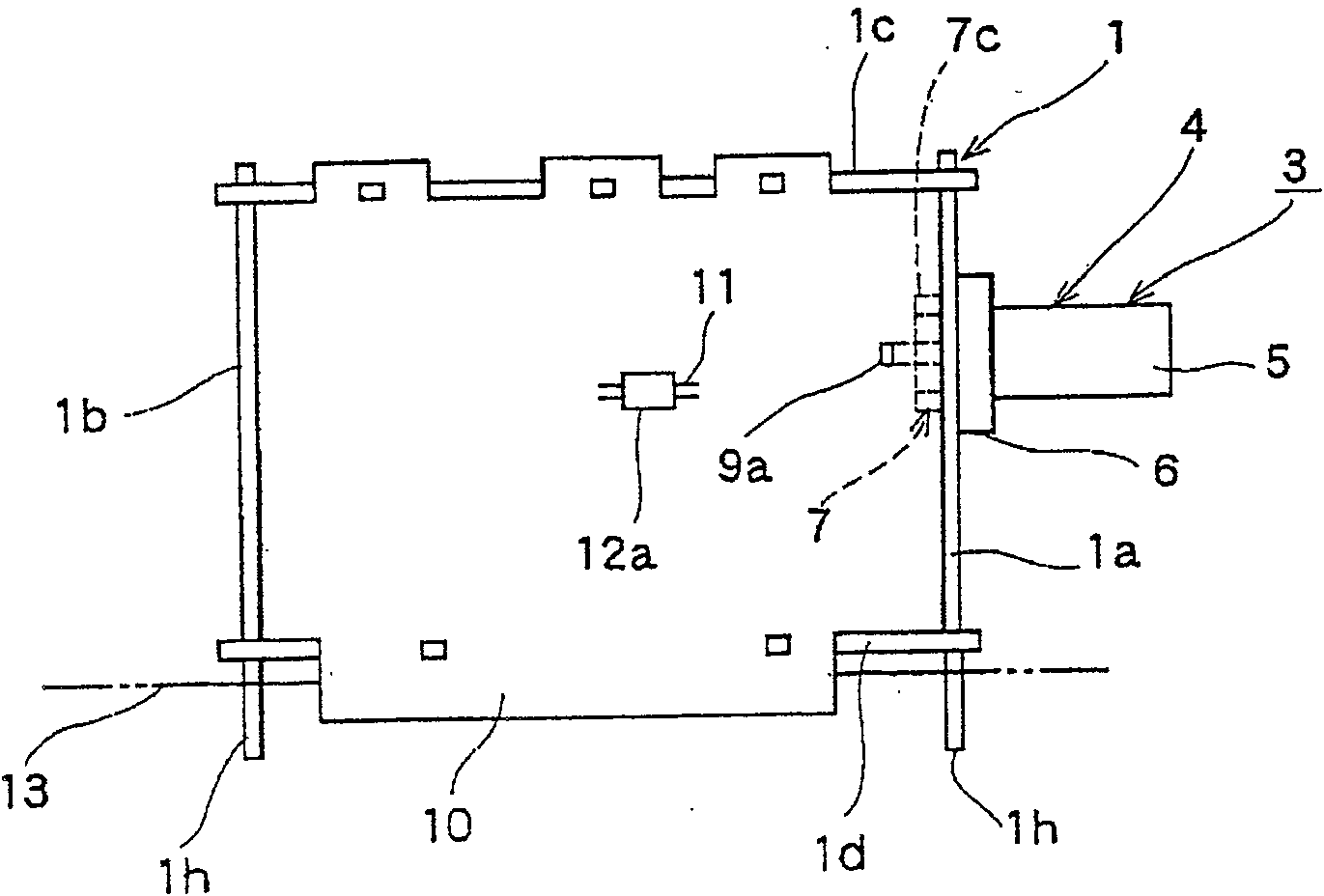

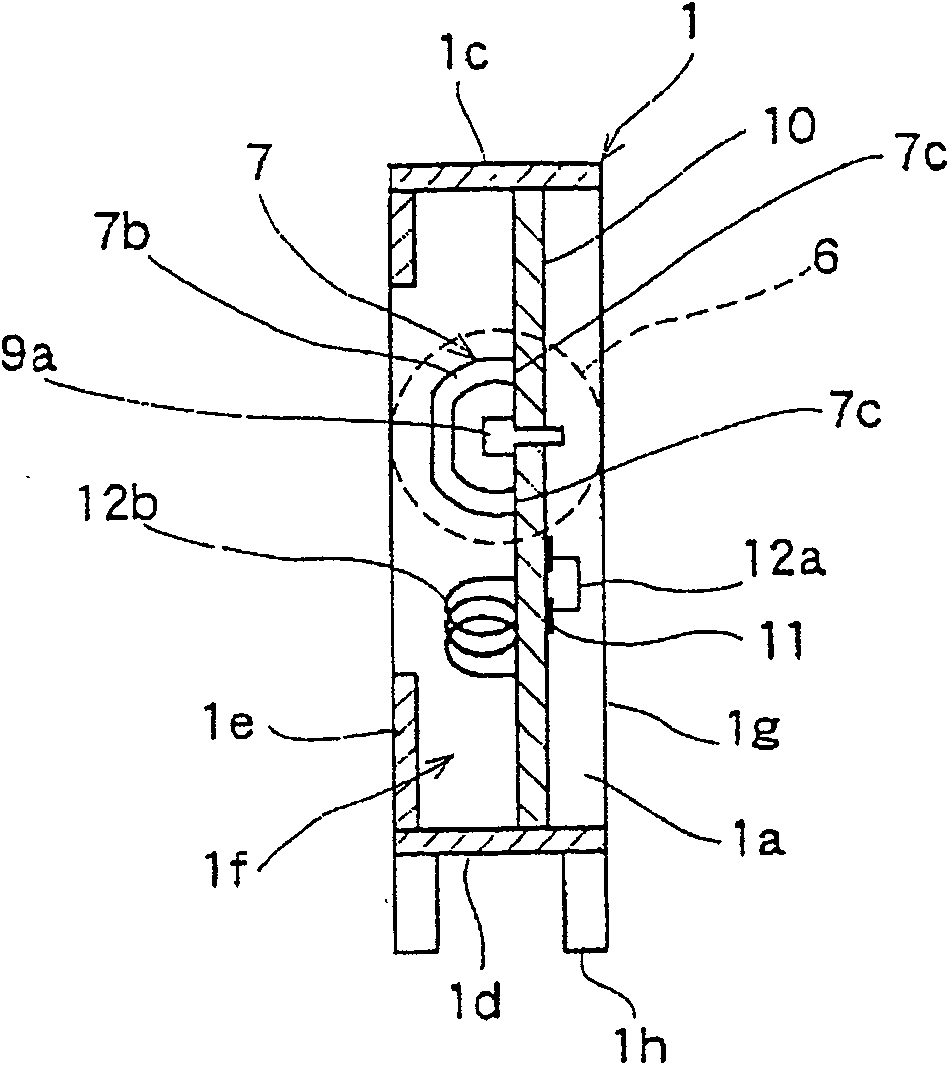

[0040] The accompanying drawings of the high-frequency equipment of the present invention are described, then figure 1 It is a front view of the first embodiment of the high-frequency device of the present invention, figure 2 It is a side view of the first embodiment of the high-frequency device of the present invention, image 3 It is a sectional view of main parts of the first embodiment of the high-frequency device of the present invention, Figure 4 It is a perspective view of the housing of the first embodiment of the high-frequency device of the present invention, Figure 5 It is a perspective view of the coaxial connector of the first embodiment of the high-frequency equipment of the present invention, Figure 6 It is a perspective view of the frame body of the second embodiment of the high-frequency equipment of the present invention, Figure 7 It is an enlarged cross-sectional view of a main part of a third embodiment of the high-frequency device of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com