Ring shaped flat piece photoresist coating device

A gluing device and flat sheet technology, which is applied to the surface coating liquid device, coating and other directions, can solve the problems of inaccurate control of gluing width and engineering application limitations, and achieve the effect of precisely controlling the gluing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

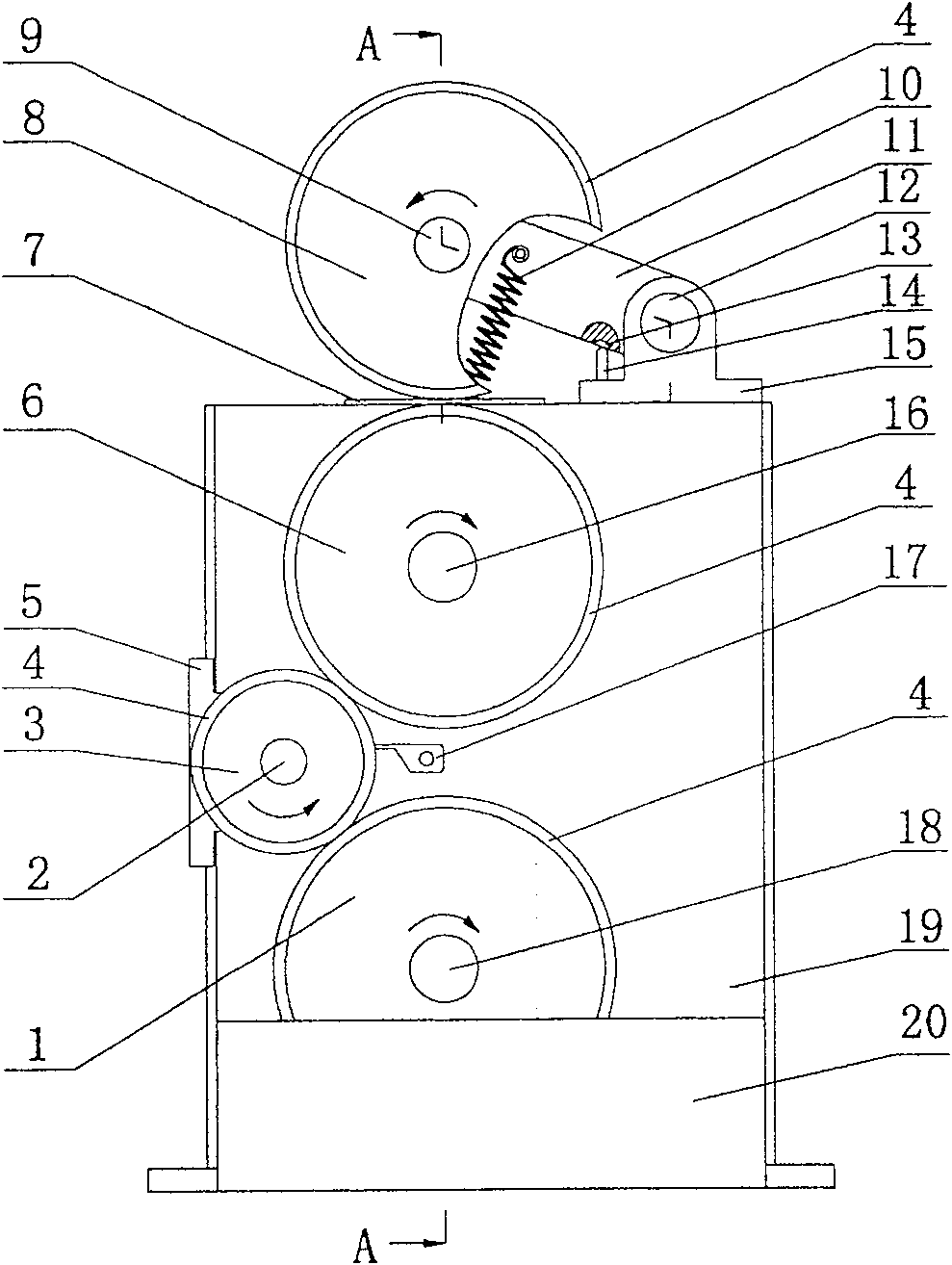

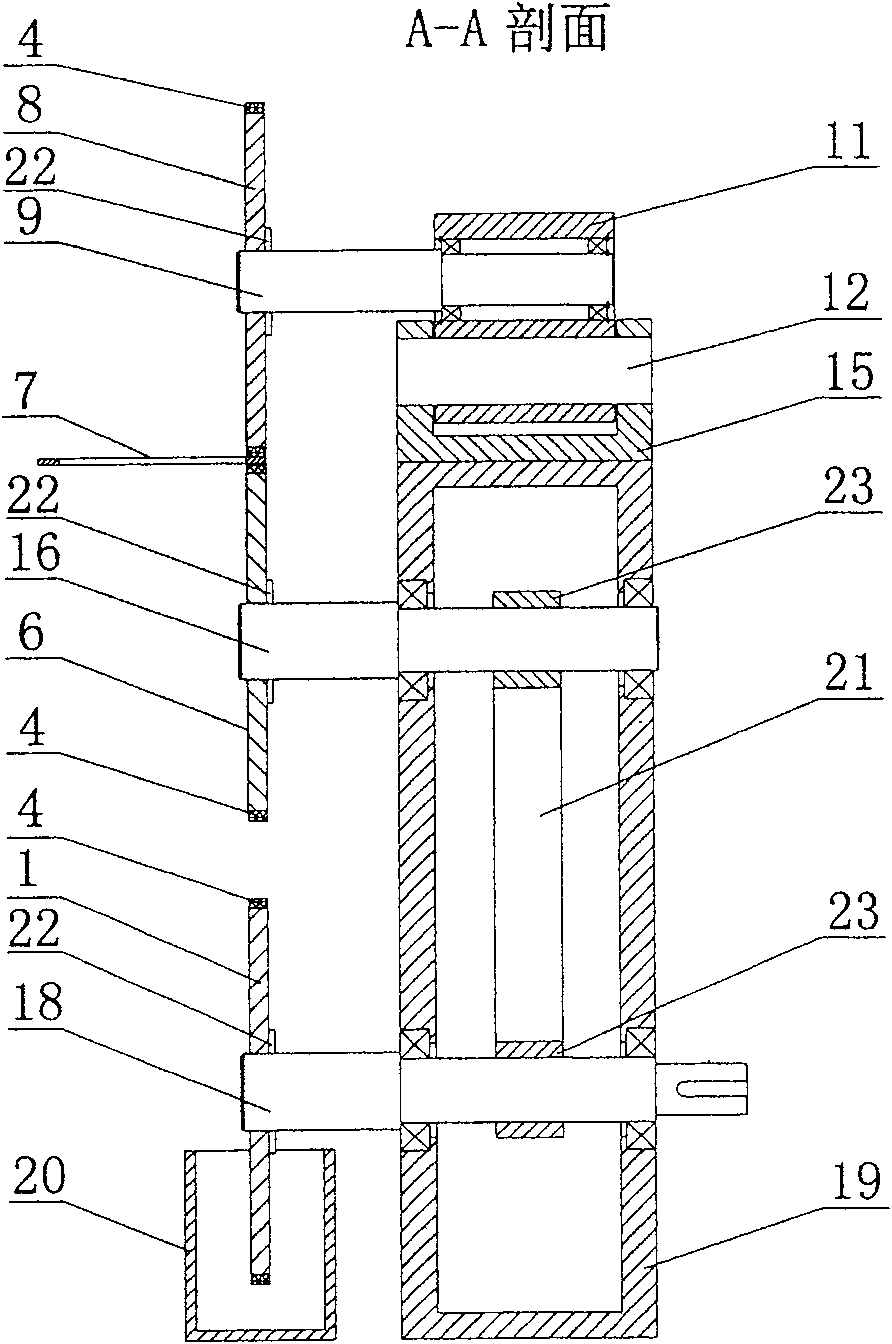

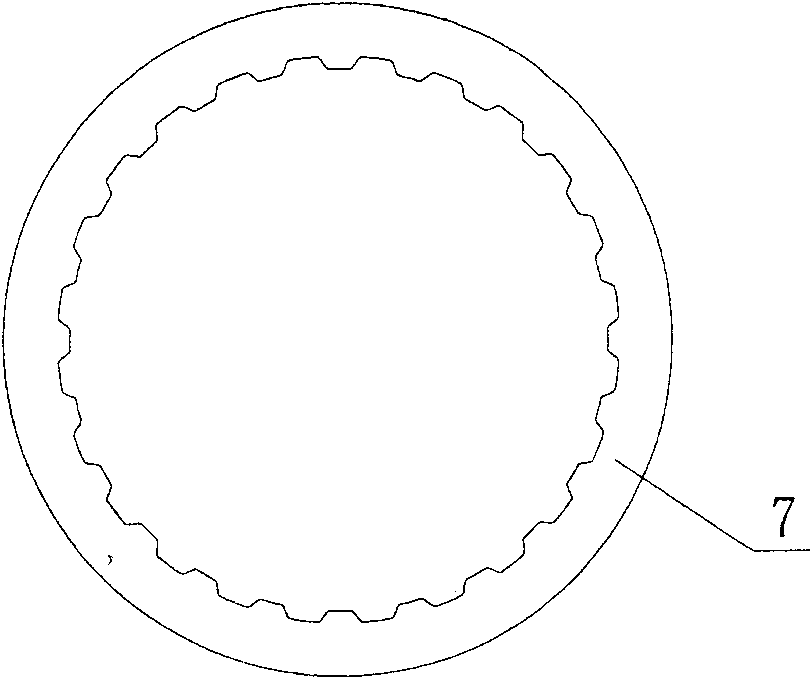

[0012] refer to Figure 1~3 , the present invention includes a rubber wheel 1, a rubber wheel 3, a rubber wheel seat 5, a rubber pressure wheel 6, a rubber pressure wheel 8, a tension spring 10, a rocker arm 11, a rocker shaft 12, a top column 14, Rocker arm seat 15, scraper plate 17, box body 19, glue groove 20, timing belt 21, adjusting gasket 22, timing pulley 23. Described lose rubber wheel, following glue pressing wheel, upper glue pressing wheel etc. big, following glue pressing wheel 6 is fixedly connected in an end of following glue pressing wheel axle 16, and following glue pressing wheel axle 16 is fixedly connected on the casing 19 by bearing. The rubber wheel 1 is fixedly connected to one end of the rubber wheel shaft 18, and the rubber wheel shaft 18 is fixedly connected on the casing 19 through a bearing, and the lower half of the rubber wheel 1 stretches into the rubber groove 20. The rubber wheel 3 is fixedly connected to one end of the rubber wheel shaft 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com