A glass edging device

A technology of glass edging and sliding rods, which is applied in the direction of grinding/polishing safety devices, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., which can solve the problems of wasting time and achieve low efficiency, high speed and time saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

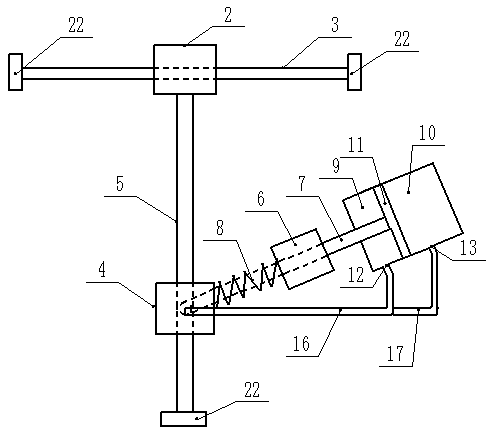

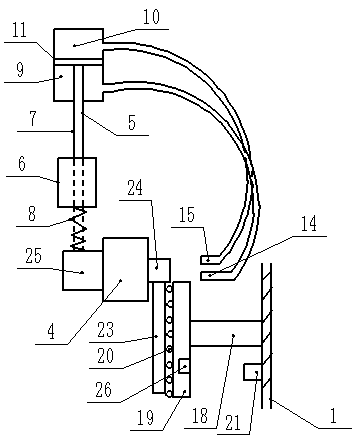

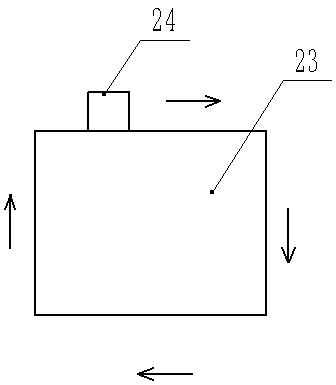

[0025] The reference signs in the accompanying drawings of the description include: frame 1, first slider 2, first slider 3, second slider 4, second slider 5, rotating block 6, push rod 7, spring 8, the first A piston cylinder 9, a second piston cylinder 10, a piston 11, a first hole 12, a second hole 13, a first air outlet 14, a second air outlet 15, a first air outlet pipe 16, and a second air outlet pipe 17. Mechanical arm 18, glass fixing plate 19, suction cup 20, PLC controller 21, limit block 22, glass 23, sharpener 24, top block 25, air extraction device 26.

[0026] Such as figure 1 , figure 2 As shown, a glass edging device includes a frame 1, a first slide bar 3 arranged horizontally is installed on the top of the frame 1, and limit blocks 22 are installed at both ends of the first slide bar 3, and the limit block 22 is threaded They are respectively connected to both ends of the first slide bar 3, and a chute is installed on the first slide bar 3, and the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com