A glass fiber glue machine

A technology of glue machine and glass fiber, applied in the field of glue machine, can solve the problems of inconvenient operation, poor wear resistance, poor quality of glass fiber, etc., to achieve automatic glue, improve production efficiency, and uniform glue effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention is further described below:

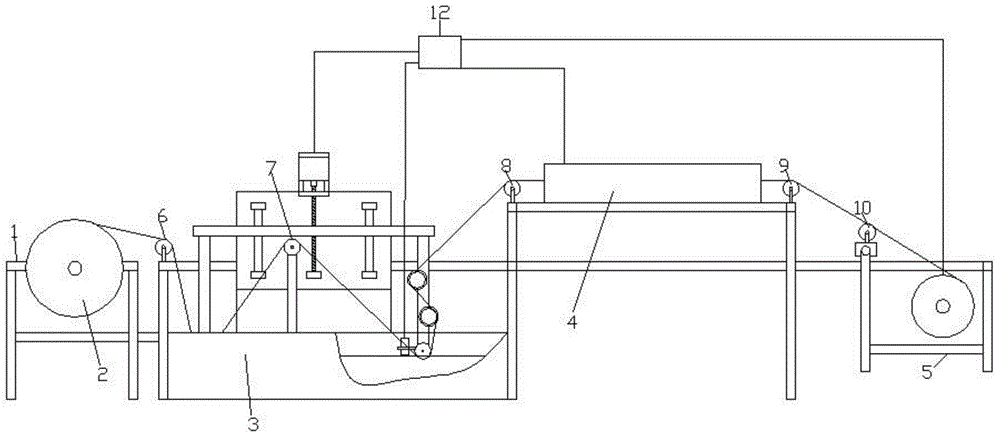

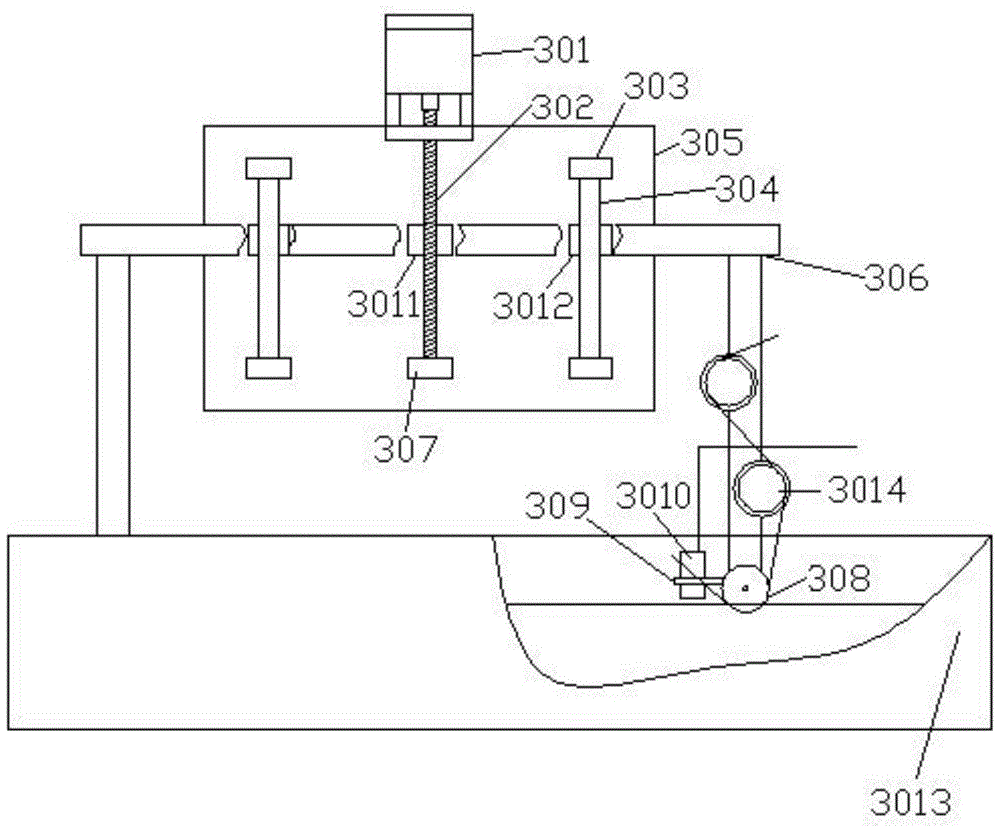

[0015] to combine figure 1 , figure 2 , image 3 , Figure 4 , a glass fiber gluing machine, comprising a glass fiber raw material bucket, a gluing mechanism, a heating mechanism, a glass fiber rolling mechanism, a glass fiber raw material cylinder 2 is arranged on the leftmost end of a bracket 1, a gluing mechanism 3 is arranged on the bracket 1 and Located on the right side of the raw material barrel 2, the first support pulley 6 is arranged between the glue passing mechanism 3 and the glass fiber raw material barrel 2 and is located on the support 1. The structure of the glue passing mechanism is: the fixing plate 305 is installed on the support 1, fixed The plate 305 is fixed, the adhesive motor 301 is installed on the upper end of the fixed plate 305, the upper end of the first lead screw 302 is connected on the adhesive motor 301, the lower end is fixed on the first lead screw holder 307, the first lead screw holder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com