Plate blank continuous casting off-line emulation system under secondary cooling and dynamic soft reduction

A technology of secondary cooling and simulation system, applied in general control system, control/adjustment system, instrument, etc., can solve the problems affecting the internal quality of casting slab, center looseness, etc., achieve good scalability, improve smooth transition, improve The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

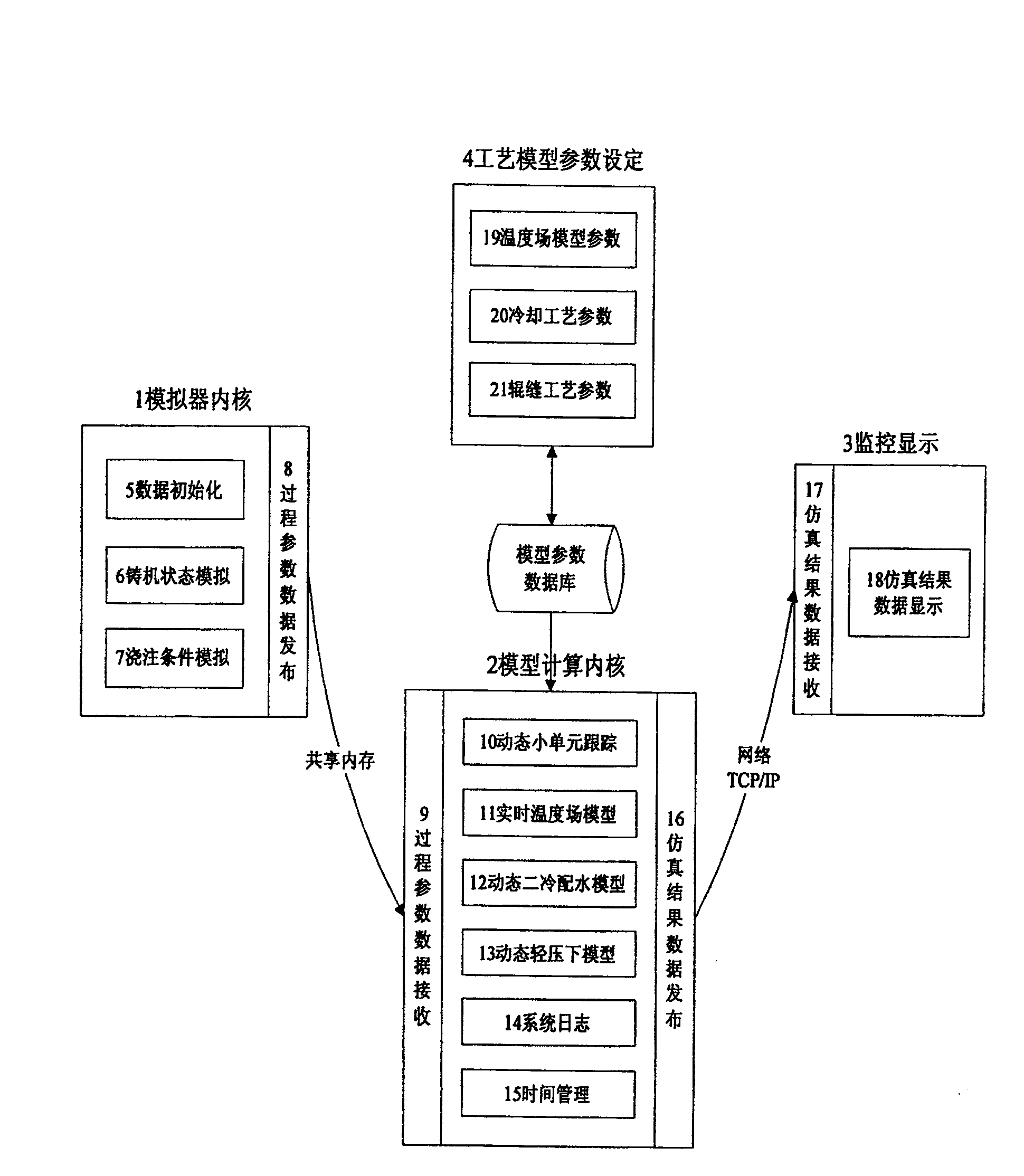

[0021] refer to figure 1 , before the user starts to simulate the specific control process of secondary cooling and dynamic soft reduction in slab continuous casting production, according to the results of analysis and research, the temperature field model parameter module in unit 4 is respectively set through the process model parameters 19 Determine the reasonable process parameters of the real-time temperature field calculation process, the cooling process parameter module 20 determines the reasonable supporting secondary cooling water distribution process, and the roll gap process parameter module 21 determines the reasonable supporting roll gap control process in the implementation process of dynamic soft reduction.

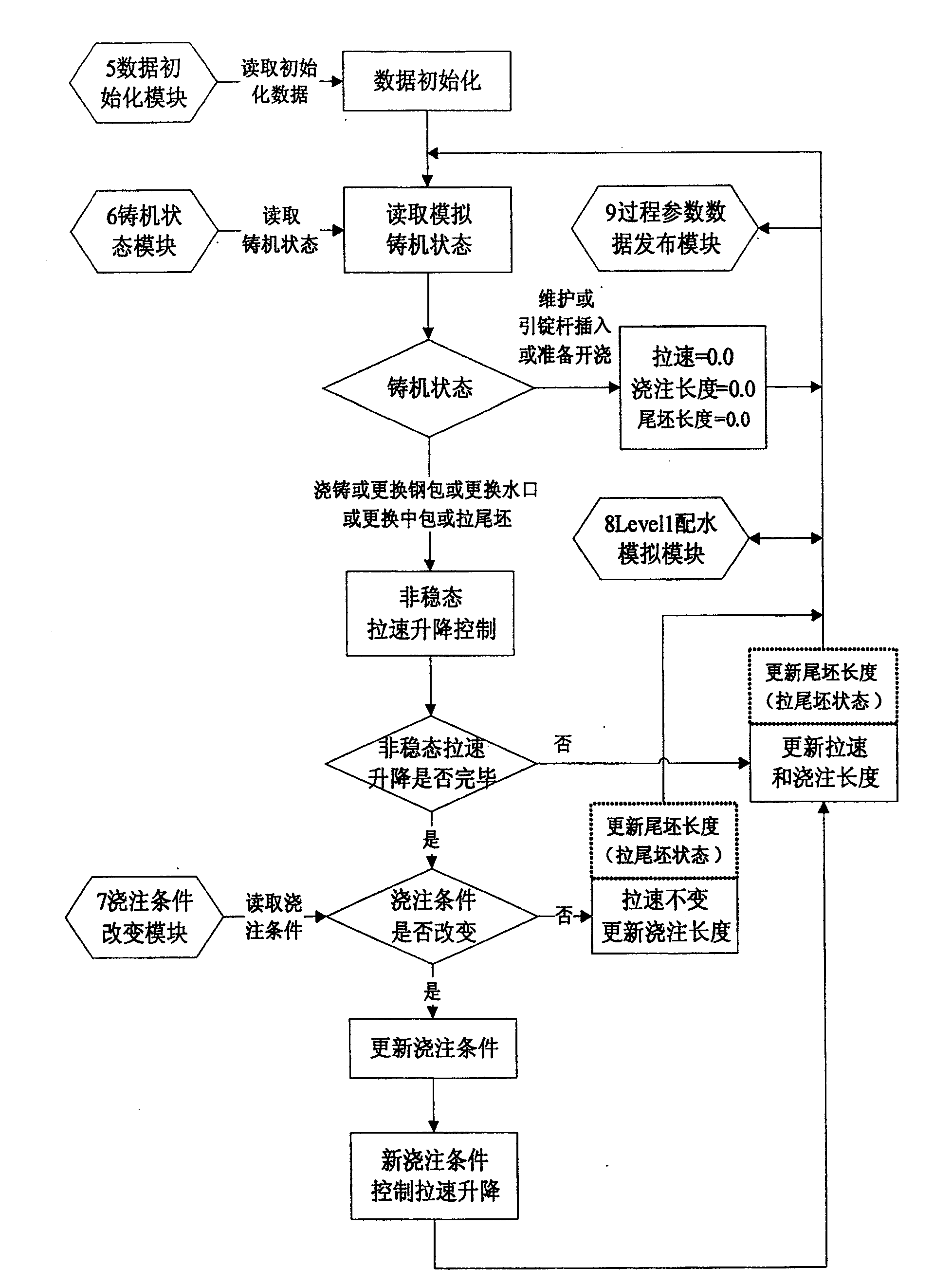

[0022] After setting the process parameters reasonably, refer to figure 2 , the user inputs the initialization data through the data initialization module 5 according to the actual needs, and switches the casting machine status through the casting machine s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com