Clamp device and clamping system using such device

A clamping device and conical technology, applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of large size and complex structure, and achieve the effect of improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

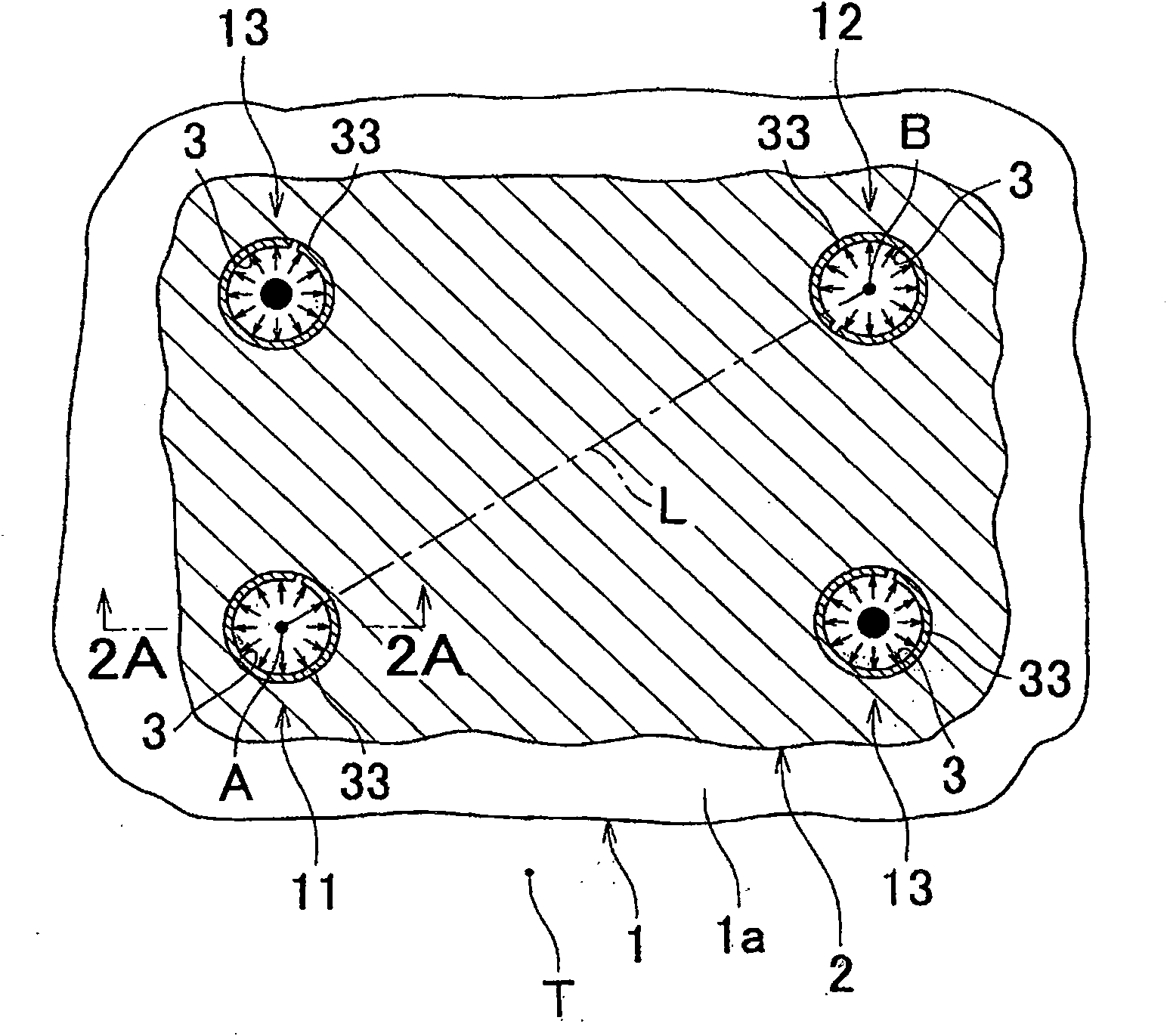

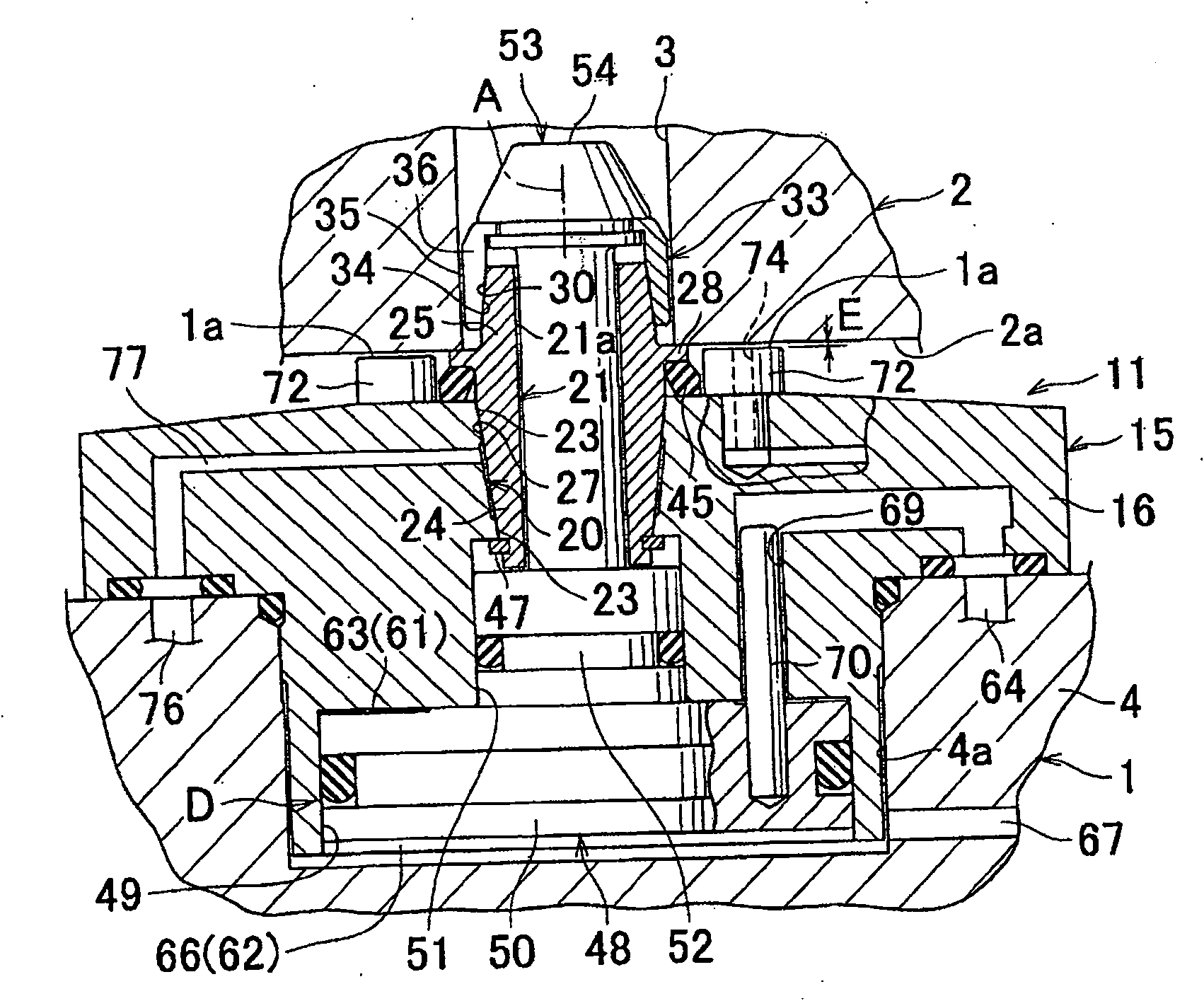

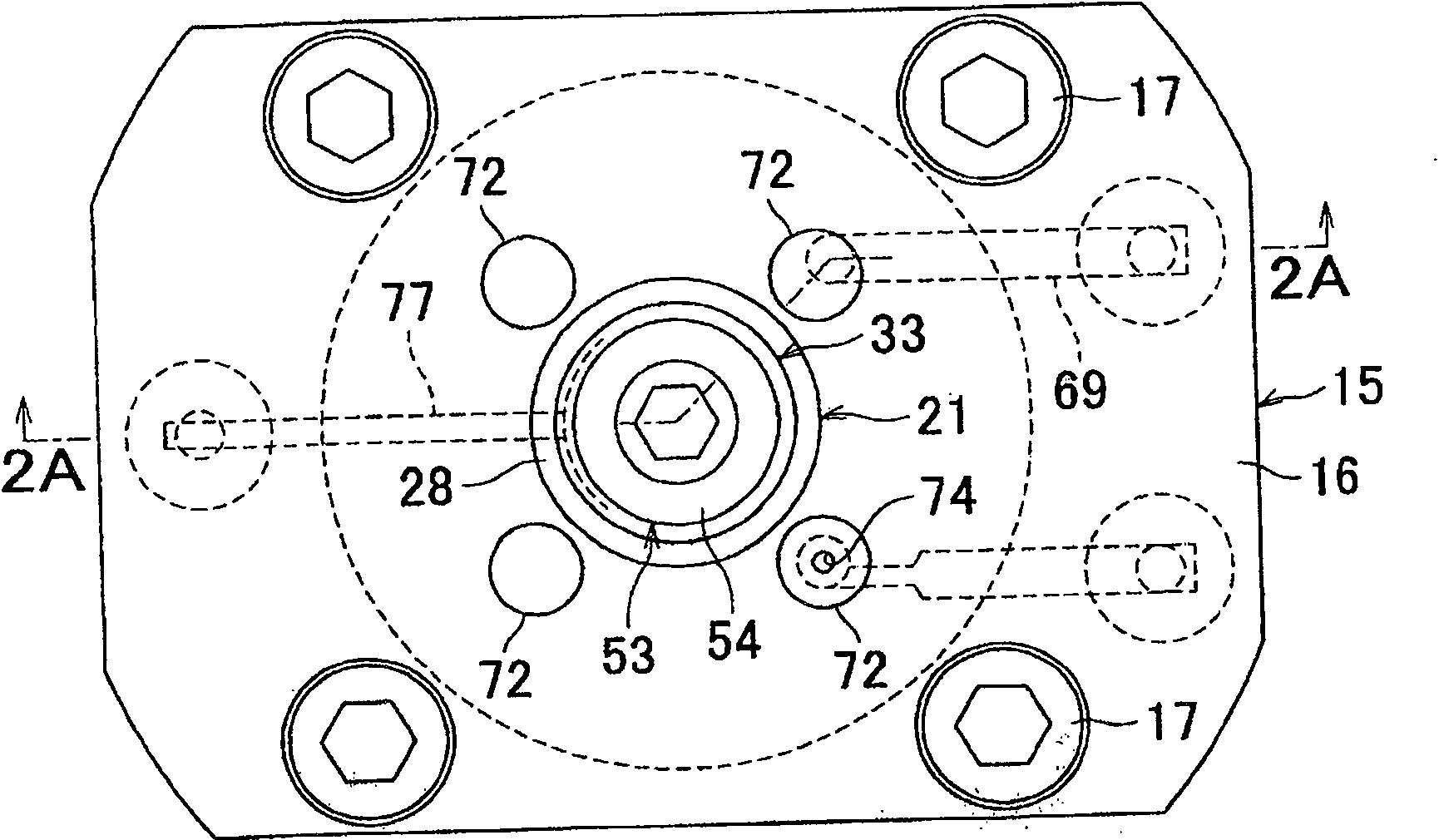

[0064] Figure 1-Figure 7B One embodiment of the present invention is shown and exemplifies the application of the clamping device of the present invention to a clamping system for a work pallet.

[0065] figure 1 is a cross-sectional view of the clamping system. Figure 2A is the front view of the section of the first clamping device of the clamping system, and corresponds to the figure 1 or Figure 2B View of the cross-section taken at line 2A-2A. Figure 2B is a top view of the clamping device. Figure 3A-Figure 4B is the view that explains the operation. Figure 5A-Figure 5C Exemplary variants of the first clamping device are shown. Figure 6A and Figure 6B A second clamping device of the clamping system is shown. Figure 6C and Figure 6D Exemplary variants of the second clamping device are shown in each case. Figure 7A and Figure 7B A third clamping device of the clamping system is shown.

[0066] Such as figure 1 and Figure 2A As shown, in this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com