Manufacturing method of rubber member for tire

A manufacturing method and component technology, applied in tires, applications, household appliances, etc., can solve the problems of poor appearance, uniformity and tire quality, thickening and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

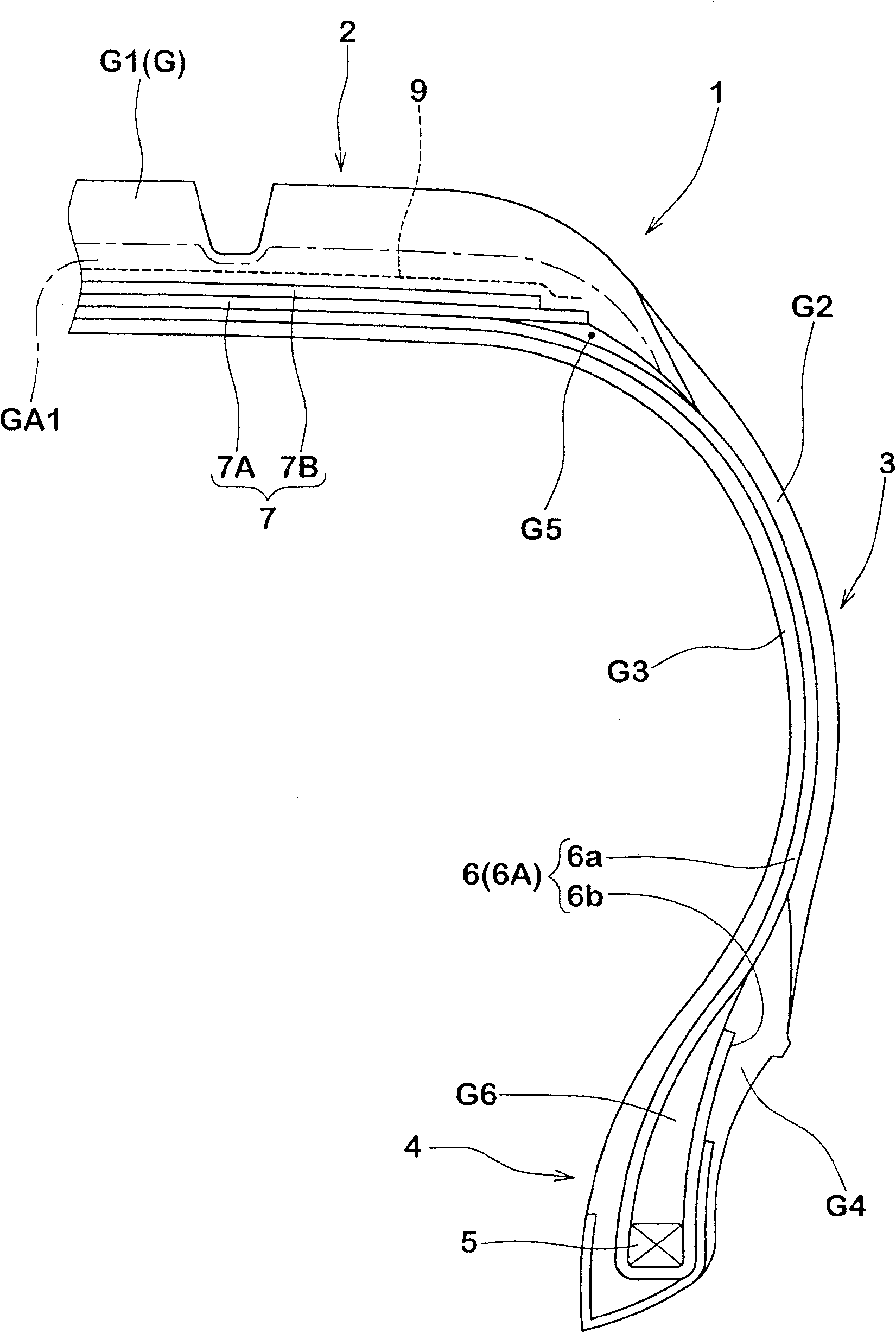

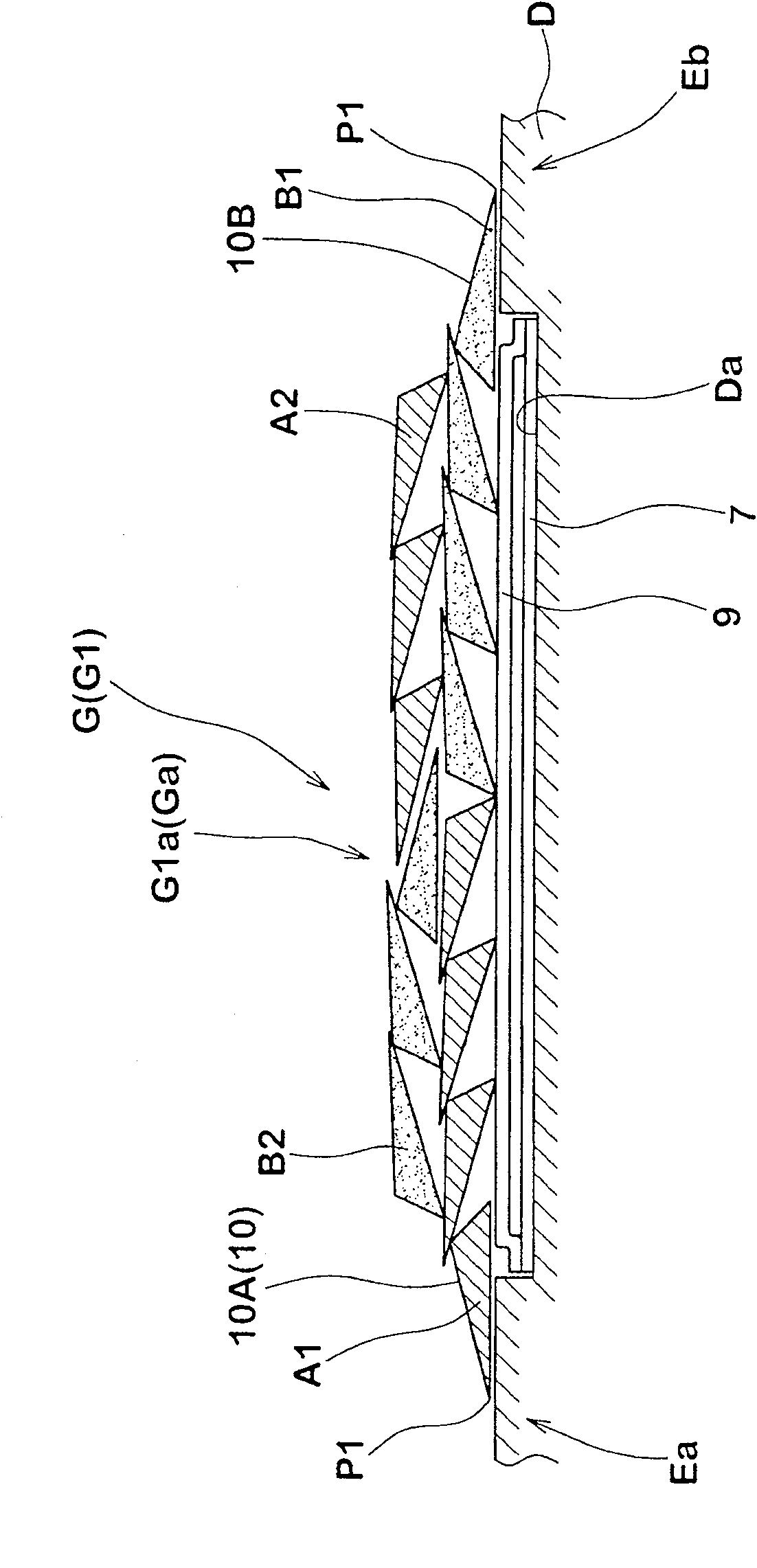

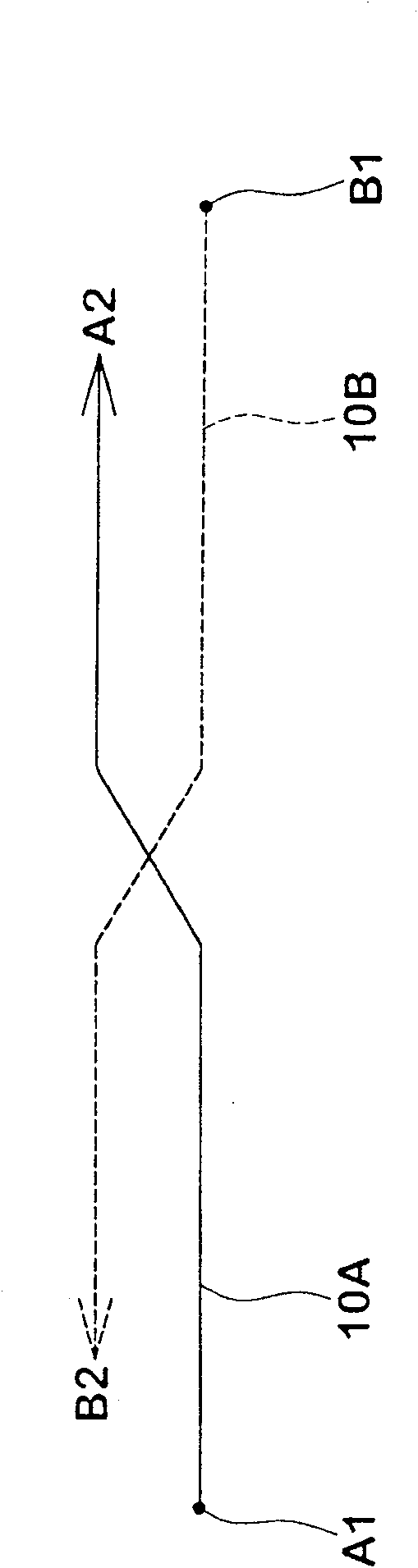

Method used

Image

Examples

Embodiment 1

[0056] A pneumatic tire (tire size 215 / 45ZR17) in which the tread rubber was formed using rubber strips having the specifications in Table 1 was manufactured, and the defect formation and uniformity of the outer surface of each test tire were compared and evaluated. Other specifications are the same except those shown in Table 1.

[0057] (1) The formation of defects

[0058] The wear of the outer surface of the tread was inspected on 30 test tires by visual inspection, and evaluated according to the following standards A, B and C.

[0059] A: No abrasion or the like was found.

[0060] B: A small defect is found. (mild level that does not require trimming)

[0061] C: A large defect is found. (Need trim level)

[0062] (2) Uniformity

[0063] According to the JASO C607 standard, the RFV (O.A.) was measured using a forced vibration (FV) test device, and the average value of 30 test tires was obtained.

[0064]

Embodiment 2

[0066] Pneumatic tires (tire size 215 / 45ZR17) were manufactured in which sidewall rubber was formed using rubber strips having the specifications in Table 2, and the handling properties of the rubber strips and the defect formation on the outer surface of each tire were compared and evaluated. In this case, the rubber strip according to the conventional embodiment uses a rubber strip having a rectangular cross-sectional shape (α=β=90°). The rubber strip according to the present embodiment uses a rubber strip having a trapezoidal cross-sectional shape (α=β). All other specifications except Table 2 are the same. In addition, each column in Table 2 describes the evaluation of the defect formation condition of the upper layer part, and the evaluation of the handling performance of the rubber strip of the lower layer part.

[0067] (1) The formation of defects

[0068] A non-defective product is set as a case where there is no wear or the like or a case where there is a small def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com