Press-fit pin

An uncompressed, arm part technology, applied in the direction of fixed/insulated contact members, electrical components, connections, etc., can solve problems such as increased contact resistance, insufficient effective contact area, increased contact pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

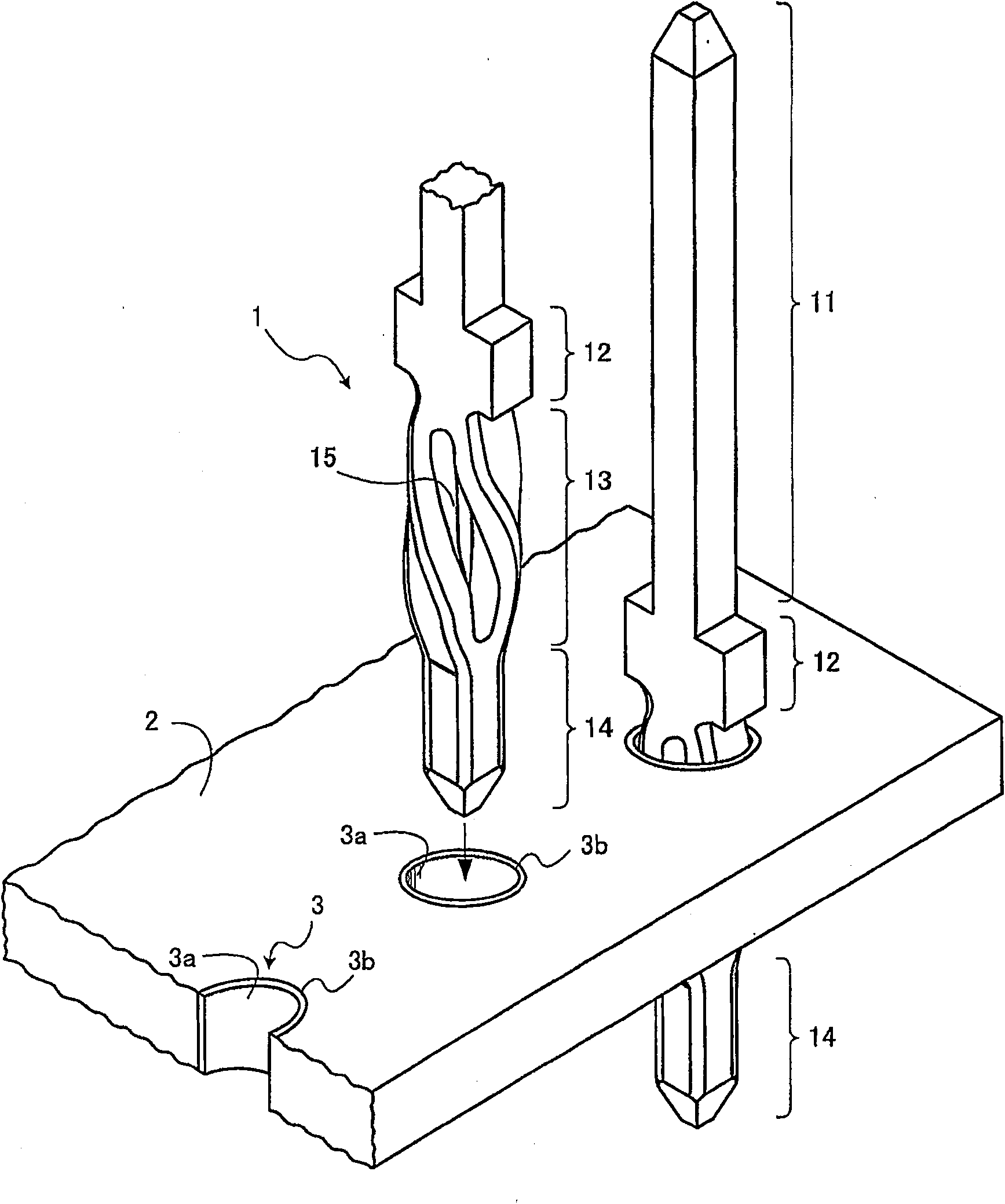

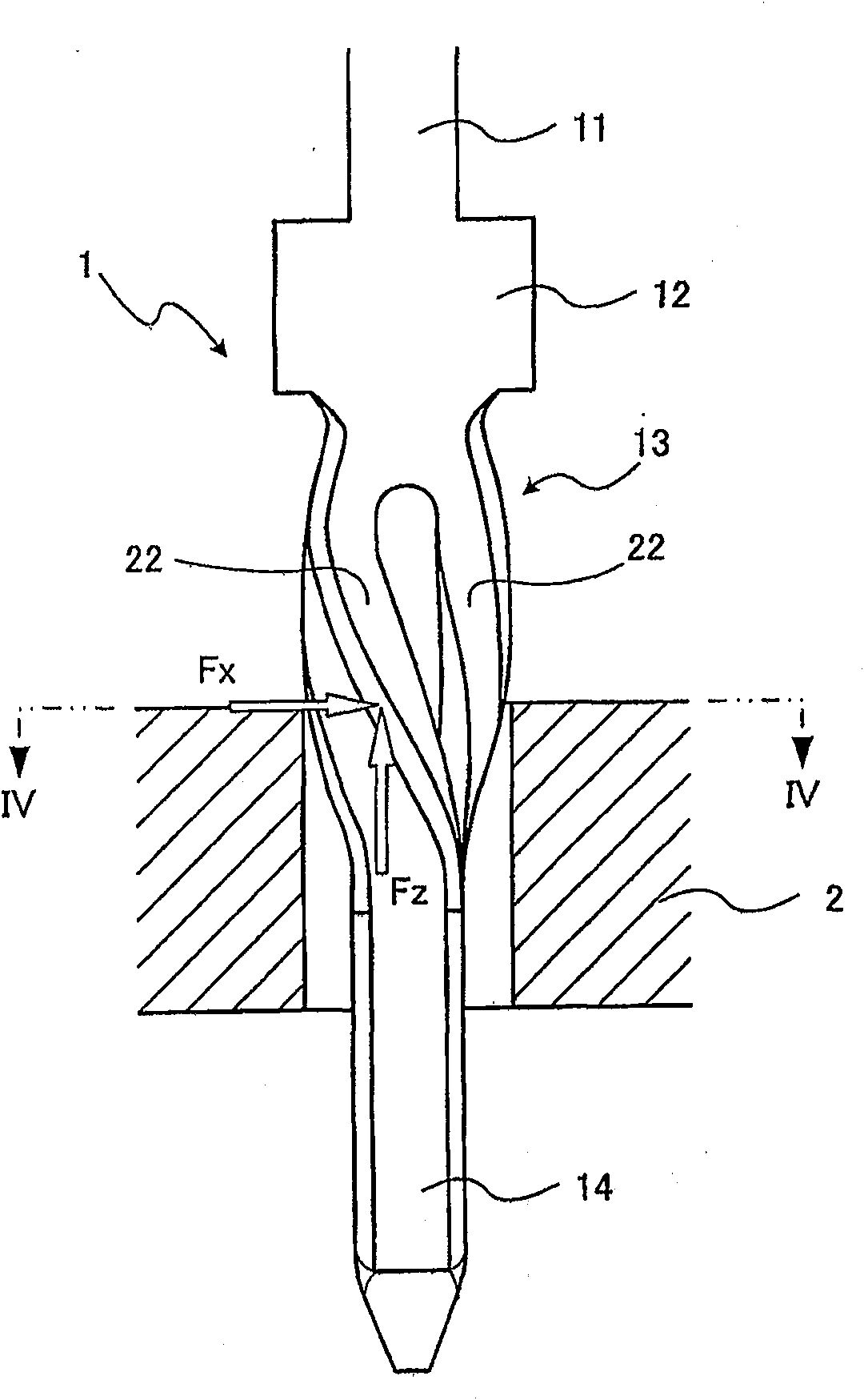

[0020] figure 1 A perspective view is shown of a press-fit pin inserted into a substrate, such as a printed circuit board, according to an embodiment of the invention. Such as figure 1 As shown, a press-fit pin 1 is press-fitted into a through-hole 3 formed on a printed circuit board 2 . The inner surface 3a of the through hole 3 is plated, and the opening 3b of the through hole 3 forms a part of the outline of a circuit pattern (not shown). A press-fit pin 1 press-fitted into a printed circuit board 2 mechanically secures a male connector thereto (not shown), forming a terminal of the male connector. The male connector mounted to the printed circuit board 2 is configured to connect to a mating connector, ie a female connector, thereby electrically interconnecting the terminals of the two connectors.

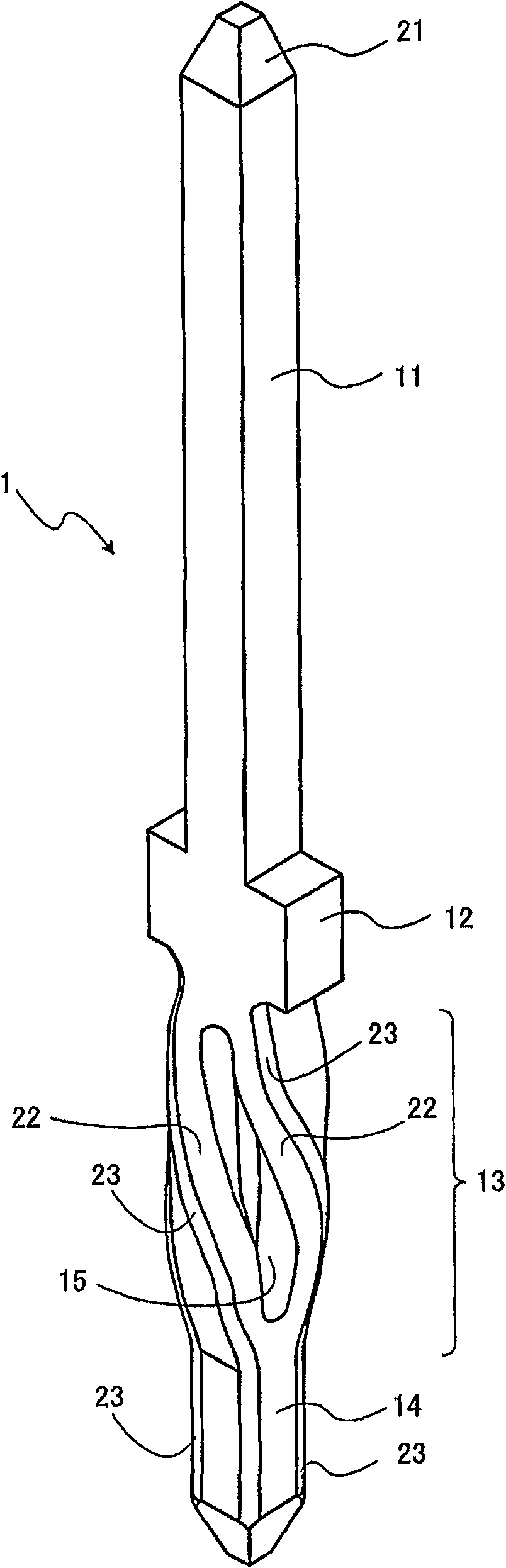

[0021] The press-fit pin 1 can be manufactured by punching out a pin of a predetermined shape from a metal plate made of copper alloy, extruding the punched pin, and then twi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com