Material used for manufacturing microwavetempering machine and defrosting device therefrom

A thawer and microwave technology, applied in the field of thawer, can solve the problems of overcooking, unfavorable thawing rate, high temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present invention is used for making the material of microwave thawing device, comprises following mass percentage composition:

[0024] Alumina Al 2 o 3 86%~95% Magnesium Oxide Powder MgO 1%~4%

[0025] Silicon oxide SiO 2 3%~6% Talc powder 0.50%~2%

[0026] Kaolin powder 0.50% to 2%.

[0027] In the present embodiment, the present invention is used to make the material of microwave thawing device, and above-mentioned each component is successively:

[0028] Alumina Al 2 o 3 90% Magnesium Oxide Powder MgO 3%

[0029] Silicon oxide SiO 2 5% Talc 1% Kaolin Powder 1%.

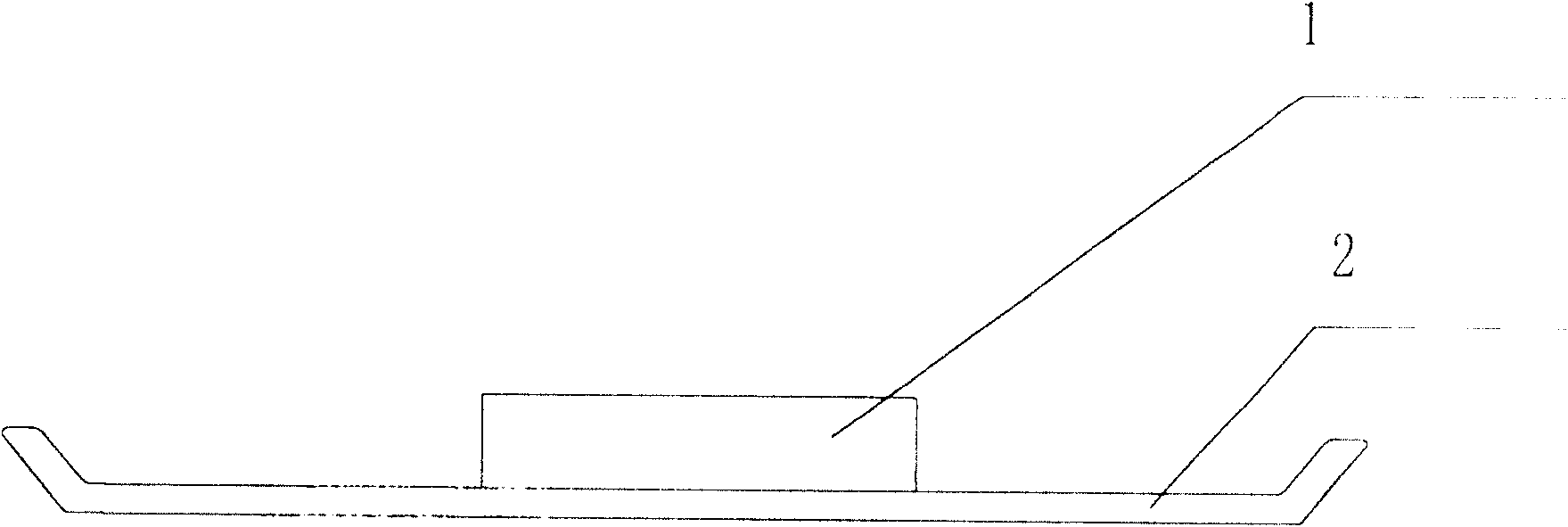

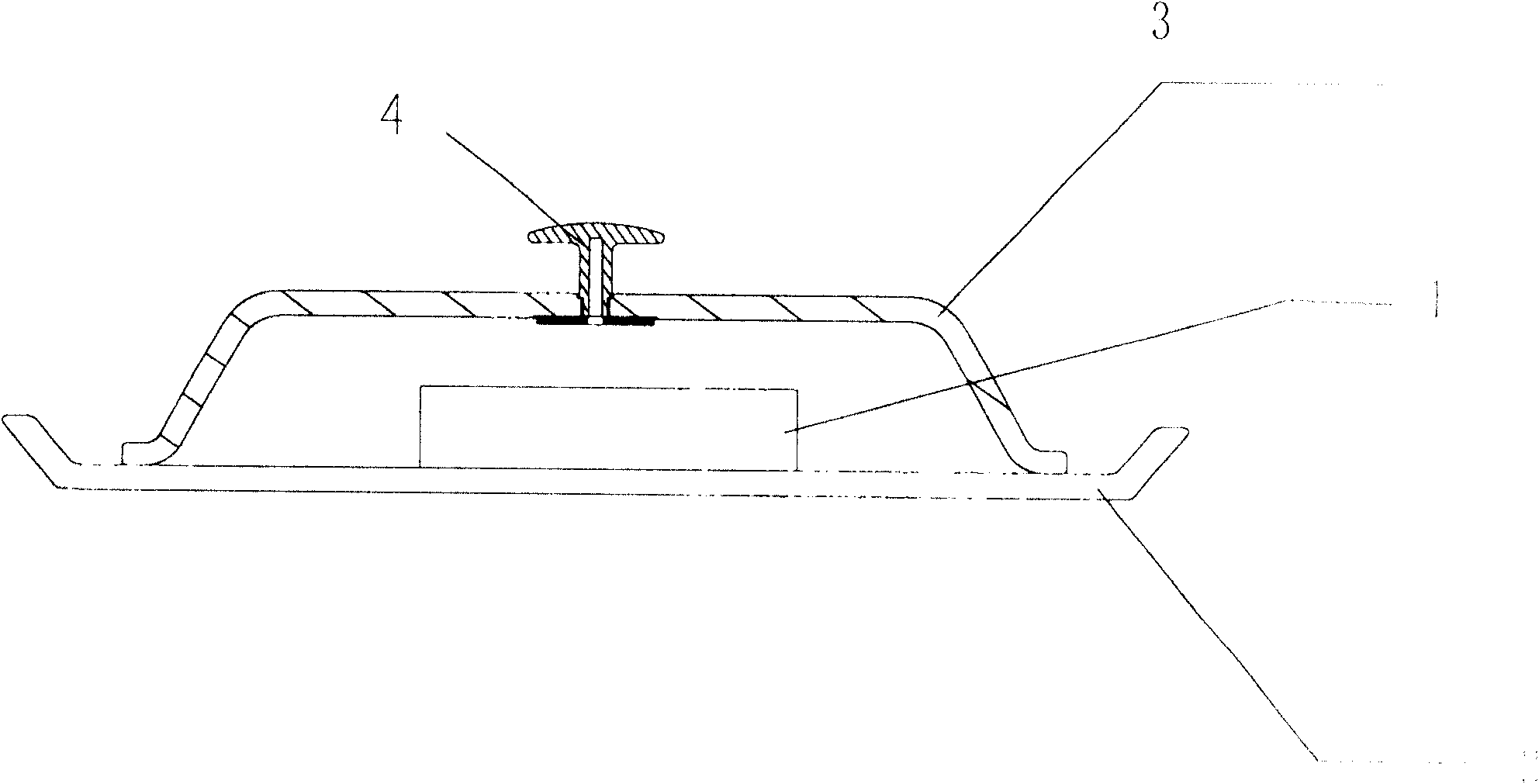

[0030] The structure schematic diagram of the embodiment of the thawing device of the present invention used in microwave ovens to thaw food is as follows figure 2 As shown, the thawing device 3 is made into a pot cover shape that can directly cover the periphery of the food 1 . In addition, the thawer 3 is provided with a handle 4 that is convenient for the user to hold. The ...

Embodiment 2

[0034] The present invention is used for making the material of microwave thawing device, comprises following mass percentage composition:

[0035] Alumina Al 2 o 3 86% Magnesium Oxide Powder MgO 4%

[0036] Silicon oxide SiO 2 6% Talc 2%

[0037] Kaolin powder 2%.

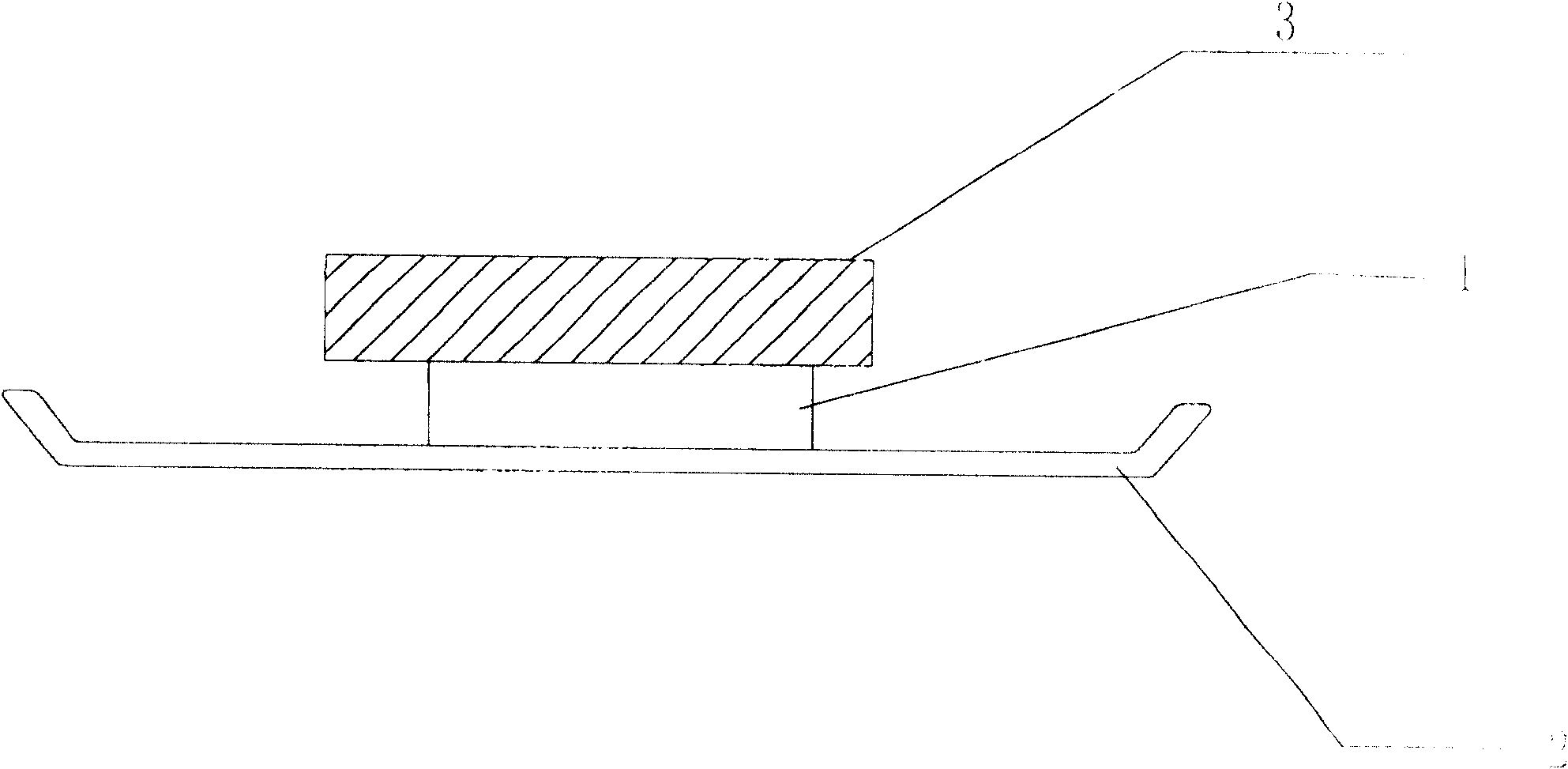

[0038] The structure schematic diagram of the embodiment of the thawing device of the present invention used in microwave ovens to thaw food is as follows image 3 Shown, the thawing device that the present invention makes with above-mentioned material is made disc shape.

[0039] The above-mentioned thawing device 3 is in partial or complete contact with the food 1 . In this embodiment, the thawing device 3 is in full contact with the food 1 .

[0040] The present invention is used for making the material of microwave thawing device, and selection area is 2212mm 2 , A ceramic sample with a thickness of 3mm was tested for its performance parameters under an electromagnetic field of 1MHz. The capacit...

Embodiment 3

[0043] The present invention is used for making the material of microwave thawing device, comprises following mass percentage composition:

[0044] Alumina Al 2 o 3 95% Magnesium Oxide Powder MgO 1%

[0045] Silicon oxide SiO 2 3% Talc 0.50%

[0046] Kaolin powder 0.50%

[0047] The structure of the thawing device of the present invention is the same as that of Embodiment 1, and the working principle of the present invention is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss factor | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com