35kv 3-phase dry type hollow current-limiting reactor

A current-limiting reactor and reactor technology, applied in transformer/inductor cooling, transformer/inductor coil/winding/connection, circuit, etc., can solve the problem that cement current-limiting reactor is bulky and cannot achieve the best effect. , poor moisture resistance and other problems, to achieve the effect of light weight, simple and reasonable structure, good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

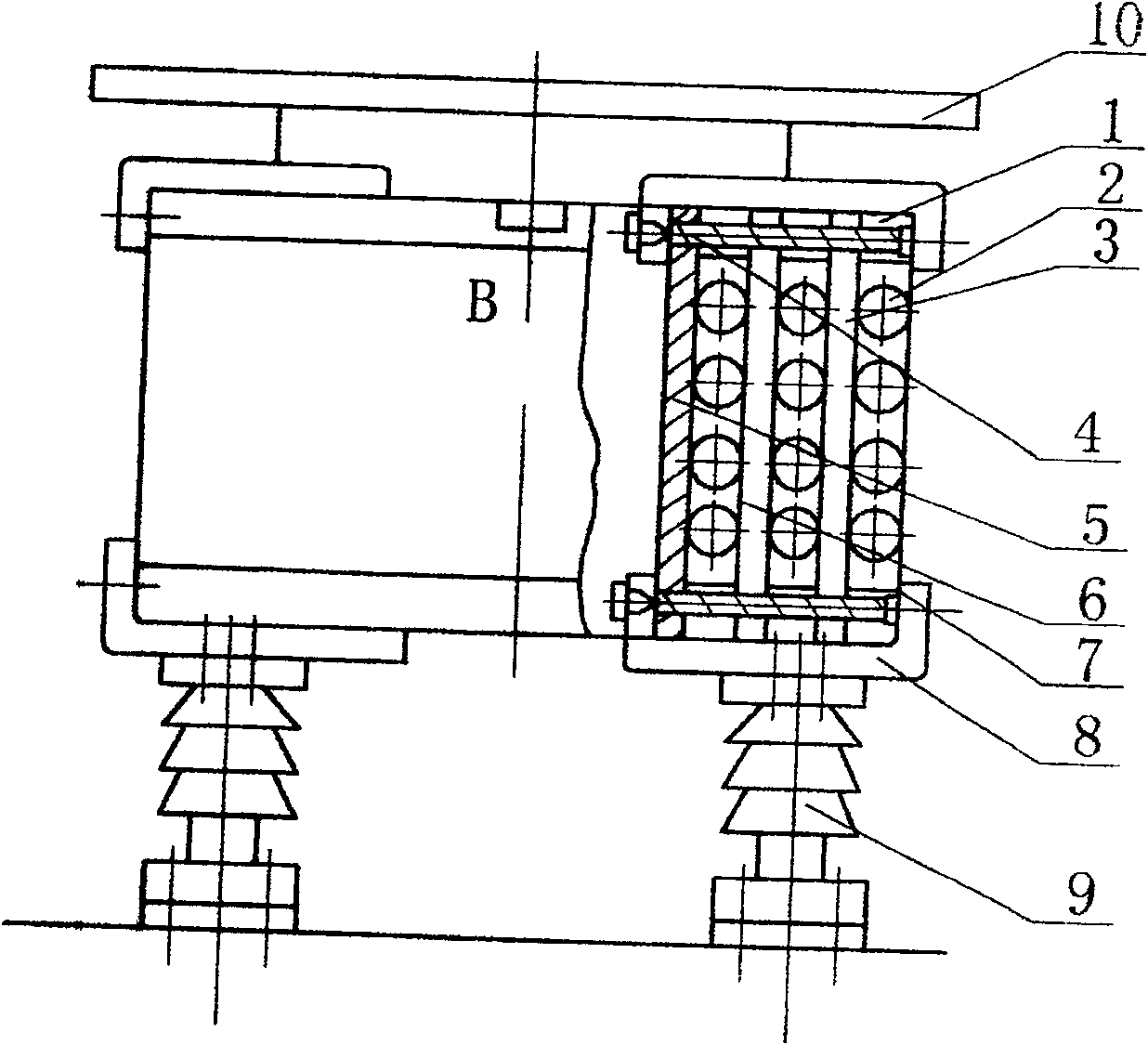

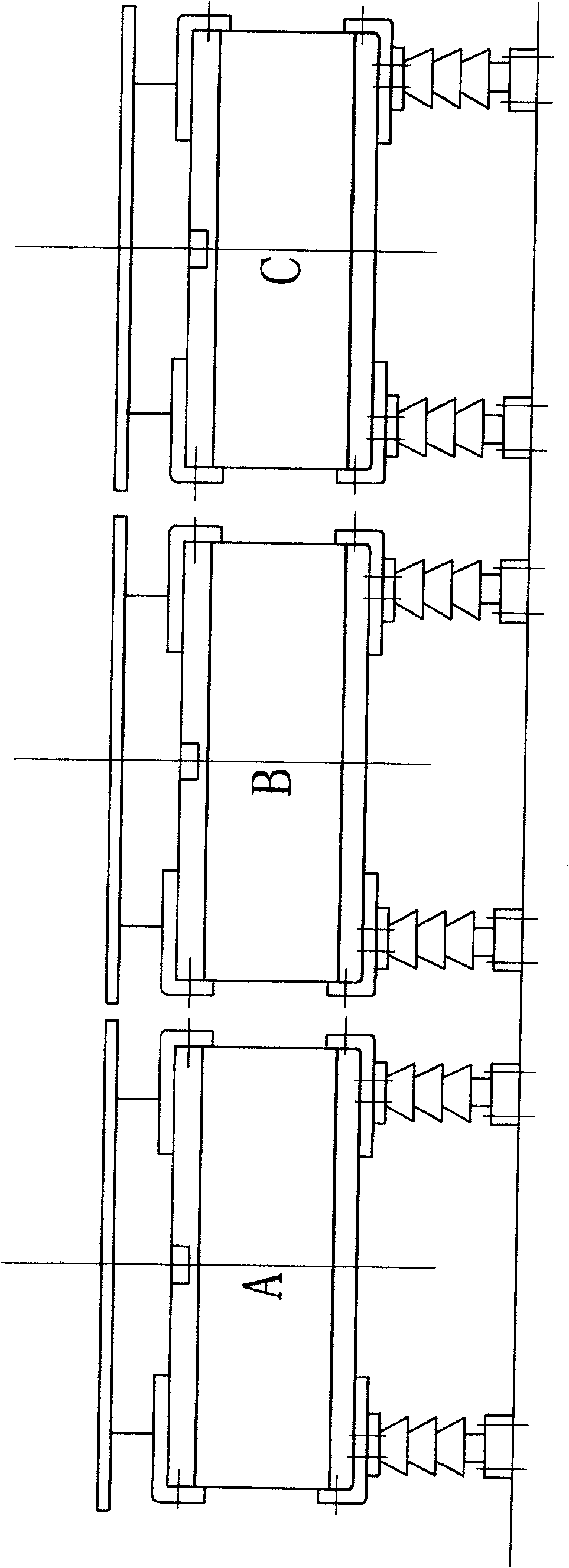

[0024] See figure 1 , 35 kV three-phase dry-type air-core current-limiting reactor, including a coil, epoxy glass cloth drum 5, and upper and lower non-magnetic steel support plates 8, and the coil of the reactor is wound with copper strands 2 composed of multiple thin copper wires On the epoxy glass cloth drum 5, the thickness of the epoxy glass cloth drum is δ=3mm on one side. Copper stranded wire 2 is covered with high temperature resistant, corrosion resistant, waterproof and moisture proof polyvinyl chloride insulation layer, each layer of coil is coated with epoxy resin curing agent 6; between each layer of coils, there is an F-class insulation cold drawn Air duct strip 3, the air duct strip is provided with ventilation grooves to make the coil air flow smoothly and there is no ventilation dead angle.

[0025] The upper and lower ends of the coil are equipped with end insulation 1 of epoxy glass fiber cloth plate formed by hot pressing, and the thickness of the end insu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com