Mechanic type friction feedback central air conditioner pipeline cleaning mechansim

A central air-conditioning, mechanical technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of variable cross-section pipes and insufficient vertical pipes, and achieve low production cost, good stability, The effect of low working environment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

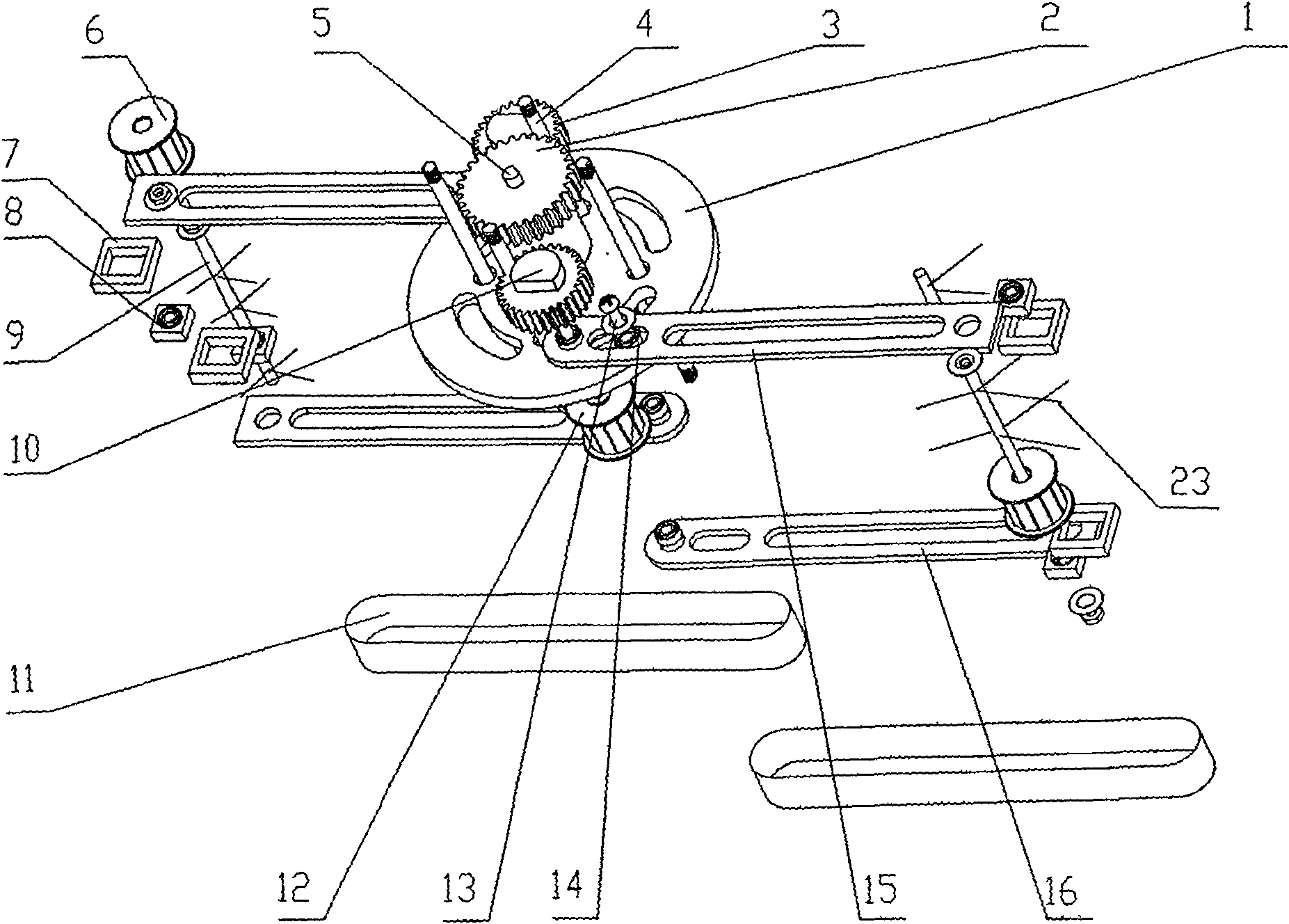

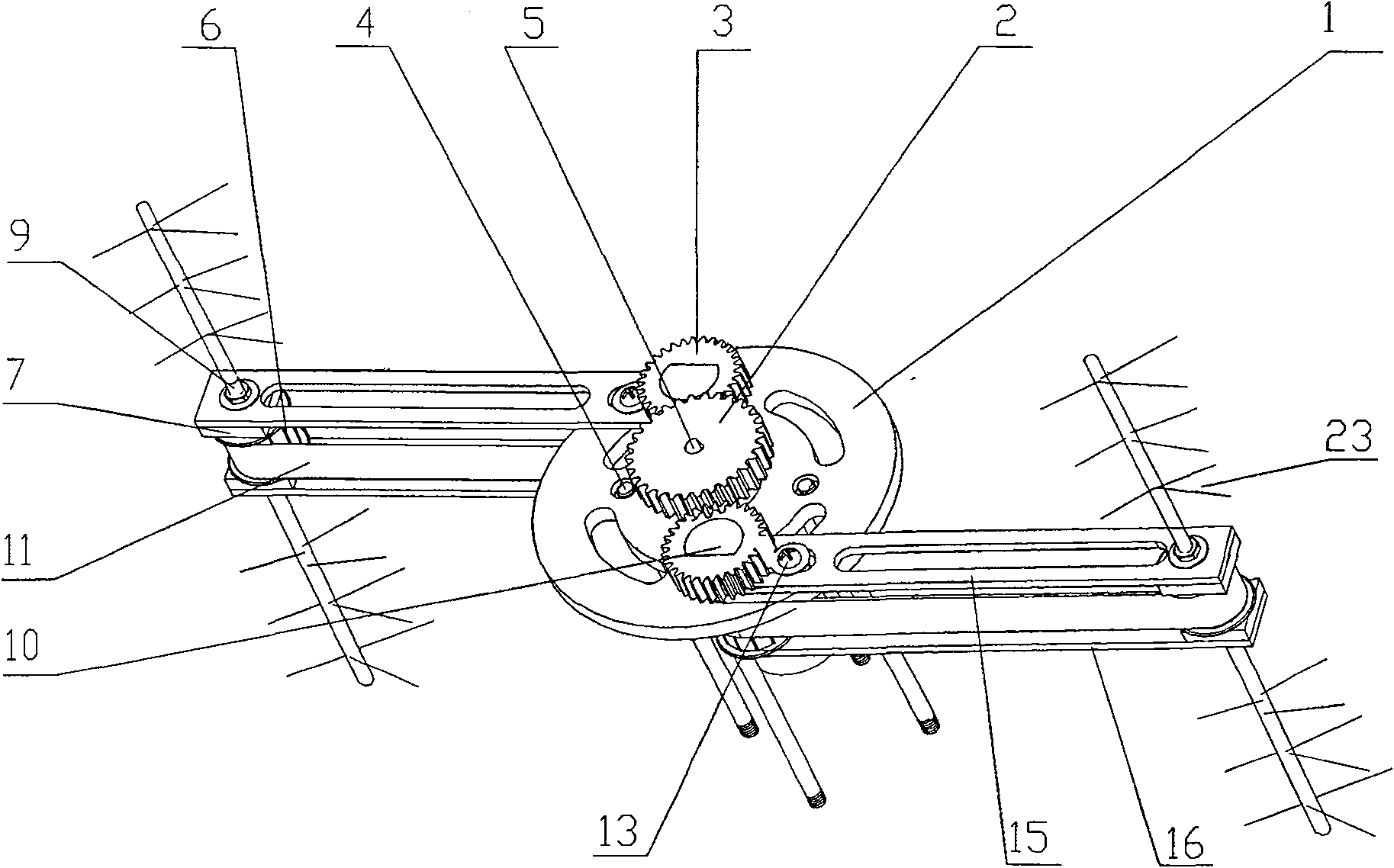

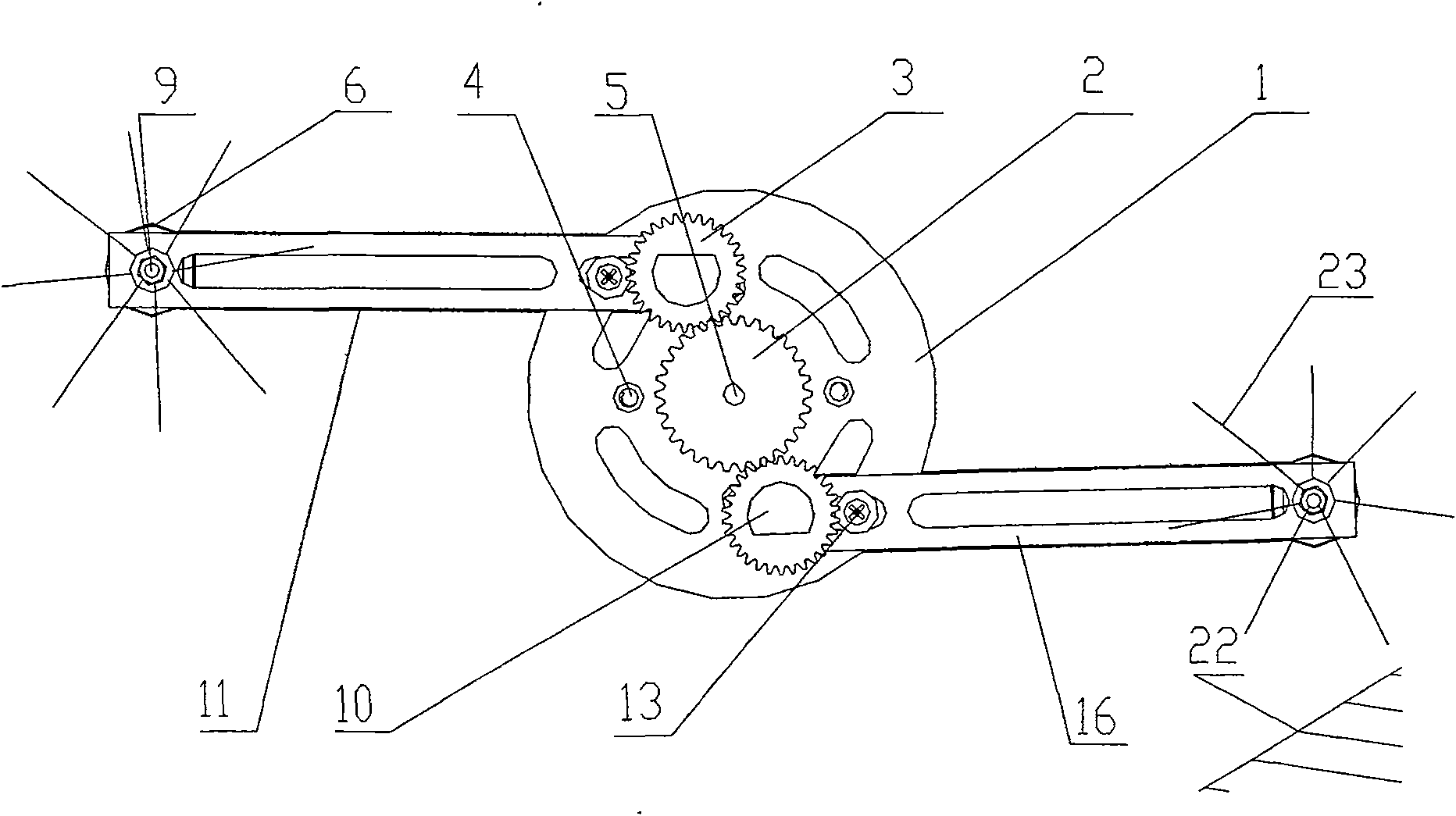

[0016] Such as figure 1 , figure 2 , image 3 As shown, the motor output shaft 5 of the present invention passes through the motor shaft hole 18 in the center of the cleaning base 1 and is fixed together with the driving gear 2. On the cleaning base 1, there are four arc chutes 17 distributed at equal intervals on the same circumference, and the two groups have the same structure. And the symmetrically distributed double chute swing mechanism is installed on the cleaning base 1, wherein: in the first group of double chute swing mechanism, the first driven gear shaft 10 passes through the first driven gear 3, the first pulley The hole at one end of clamp 15, the first chute 17 on the cleaning base, the hole at one end of the first driving pulley 12 and the second pulley clamp 16, the driving gear 2 and the first driven gear 3 mesh; the first fixed shaft 13 Pass throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com