Hydraulic press for multi-layer bamboo wood integrated material

A hydraulic press and material technology, applied in the direction of wood compression, lamination, lamination devices, etc., can solve the problems of difficult-to-process high-density materials, affect the pressure strength, and low pressure bearing capacity, so as to improve production efficiency and product quality quality, increase positive pressure, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

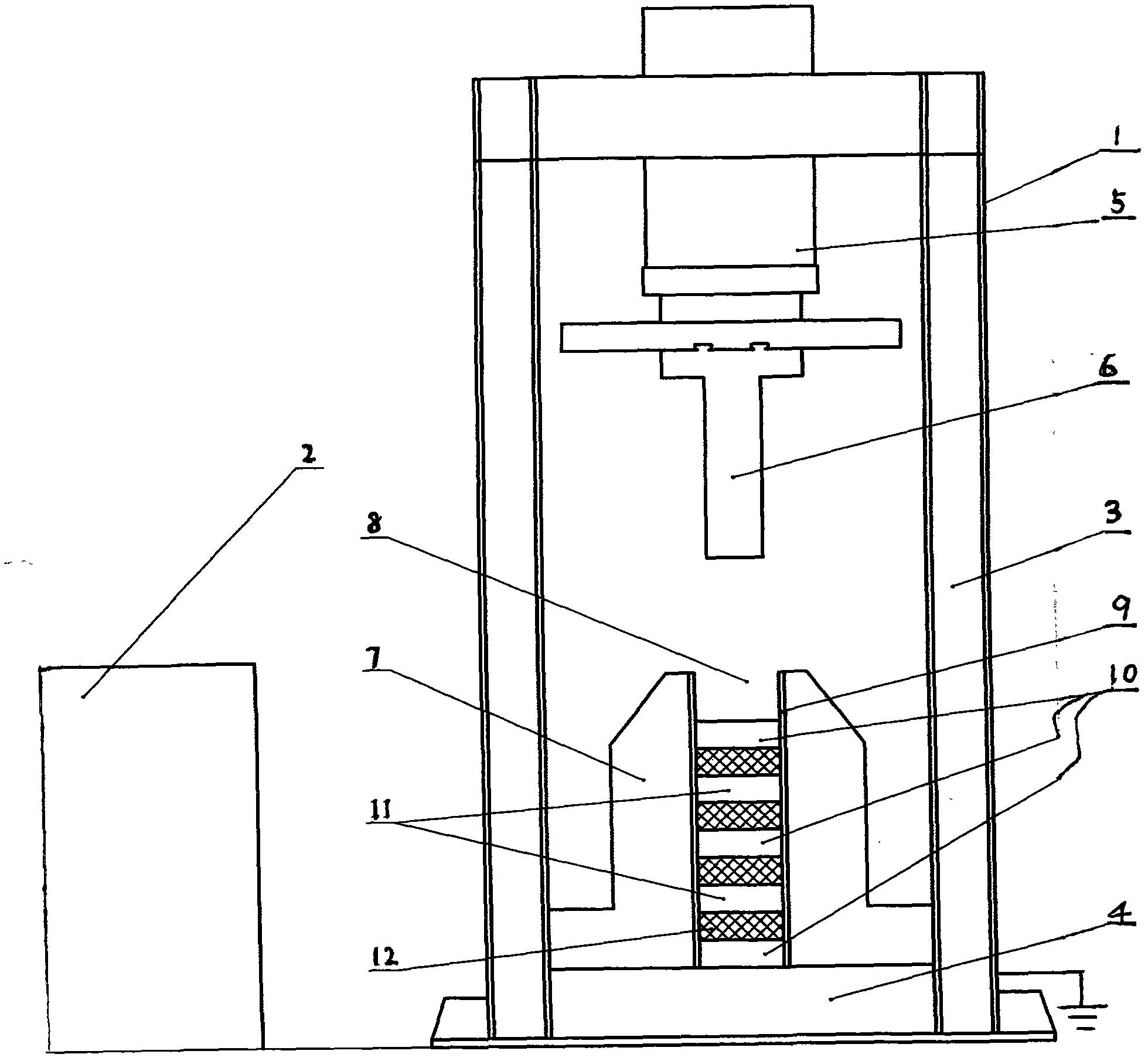

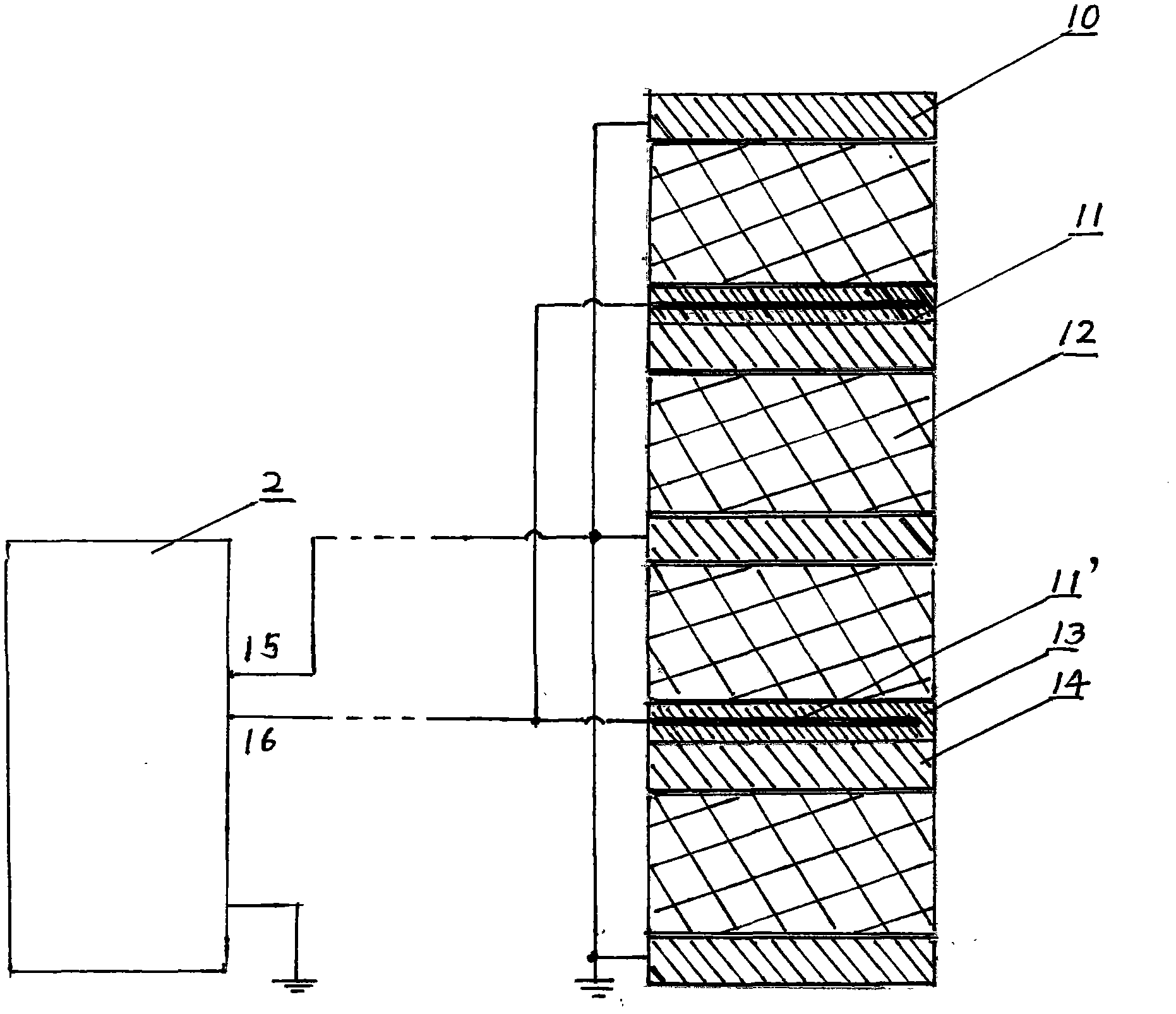

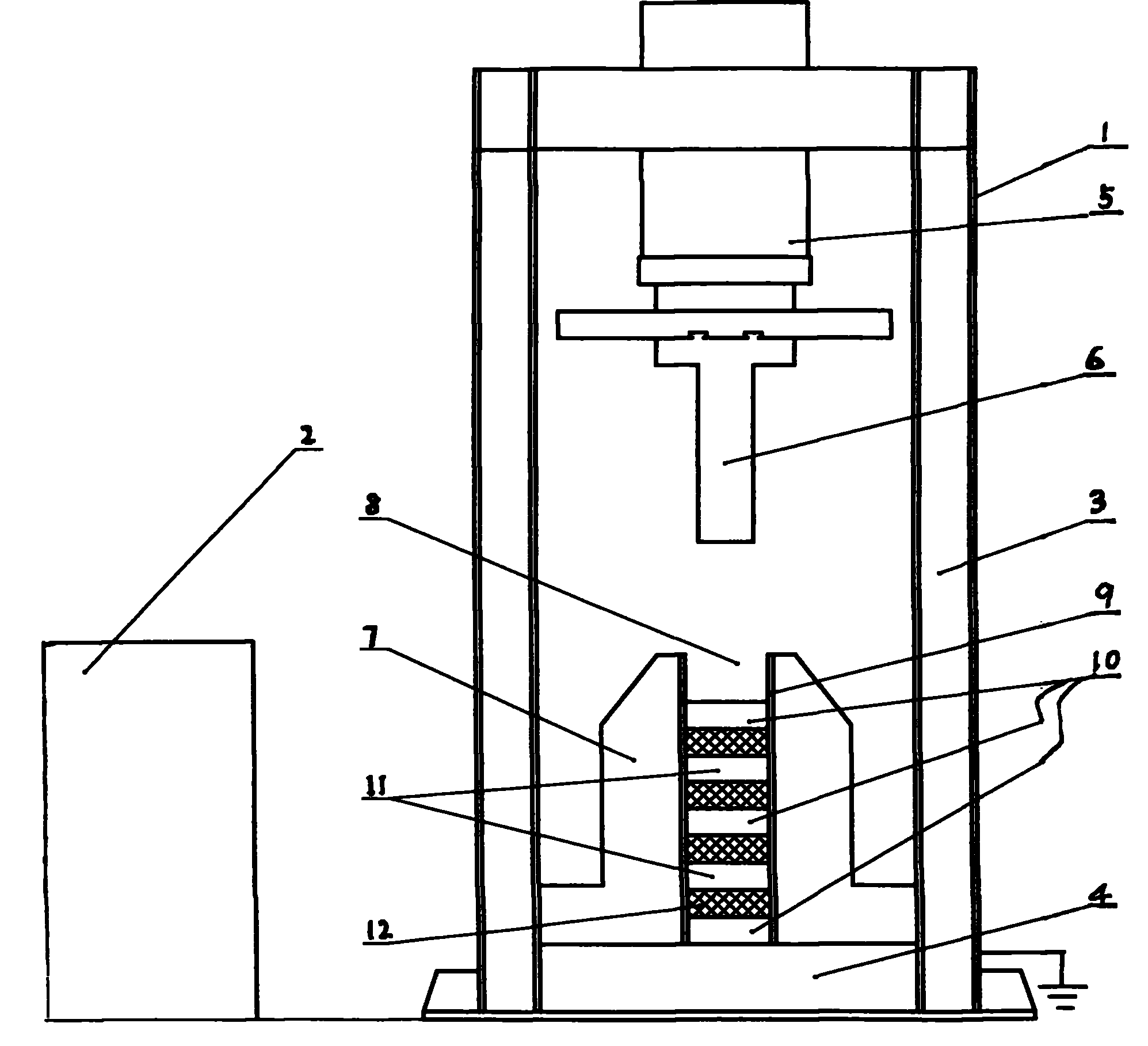

[0010] piece figure 1 And attached figure 2 An embodiment of a high-frequency heating four-layer bamboo-wood integrated material hydraulic press is provided, including a hydraulic press 1 and a high-frequency generator 2, and the hydraulic press 1 includes a frame 3, a base 4, a hydraulic cylinder 5, a lifting cylinder, a pressure head 6, and a template 7. The mold cavity 8 and the high-frequency shielding plate 9 on the side wall of the mold cavity. There are multiple layers of high-frequency heating electrode plates in the mold cavity, including 3 layers of first heating electrode plates 10 and 2 layers of second heating electrode plates 11. The 3 layers of first heating electrode plates 10 include fixed heating electrodes at the bottom of the mold cavity Plate and 2 layers of movable heating electrode plates on it, 3 layers of first heating electrode plates are connected in parallel to the first output terminal 15 of the high-frequency generator through wires, and the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com