Fastener module and heat radiating device having the same

A technology of heat dissipation device and fastener, applied in elastic/clamping device, circuit arrangement on support structure, cooling/ventilation/heating transformation, etc., can solve problems such as interference, and achieve the effect of low product height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

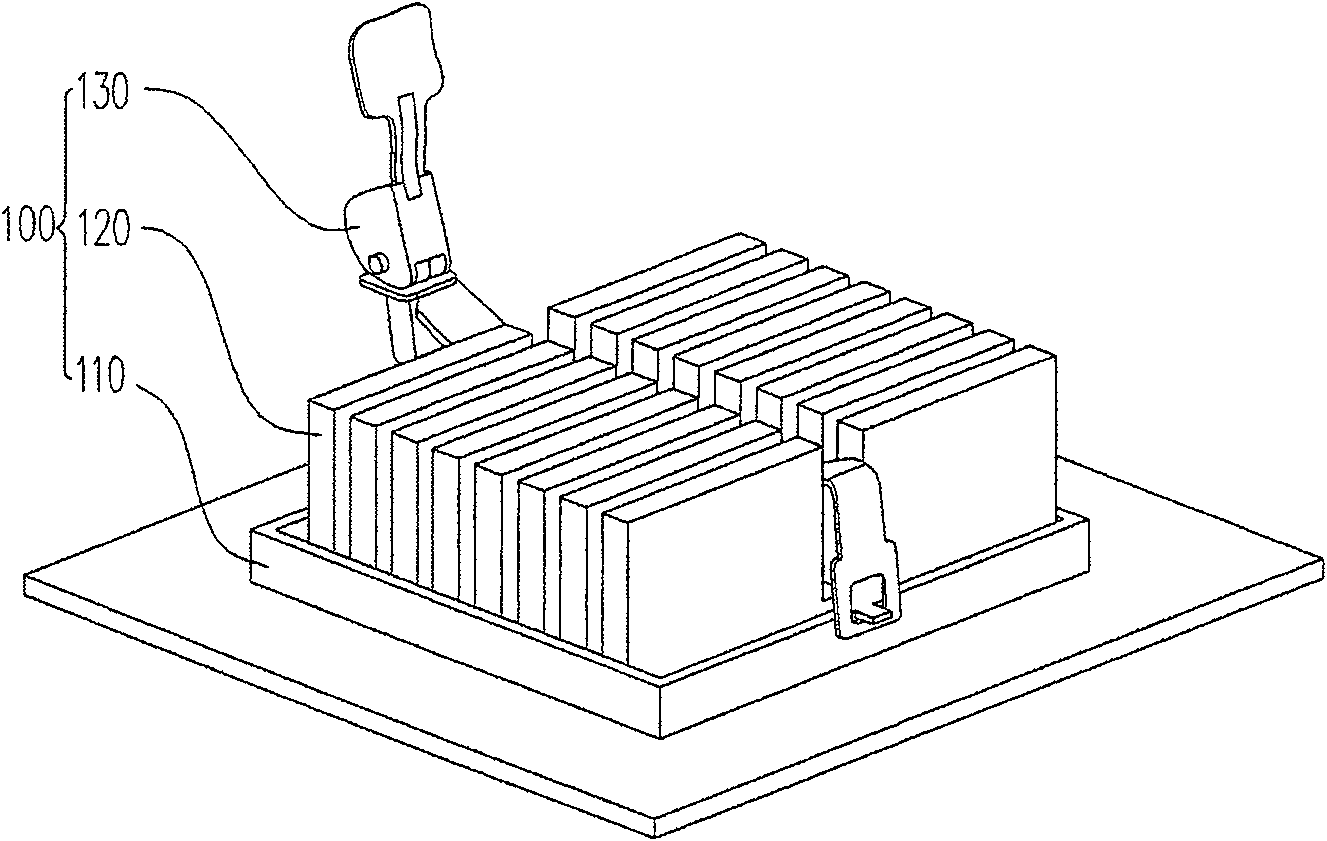

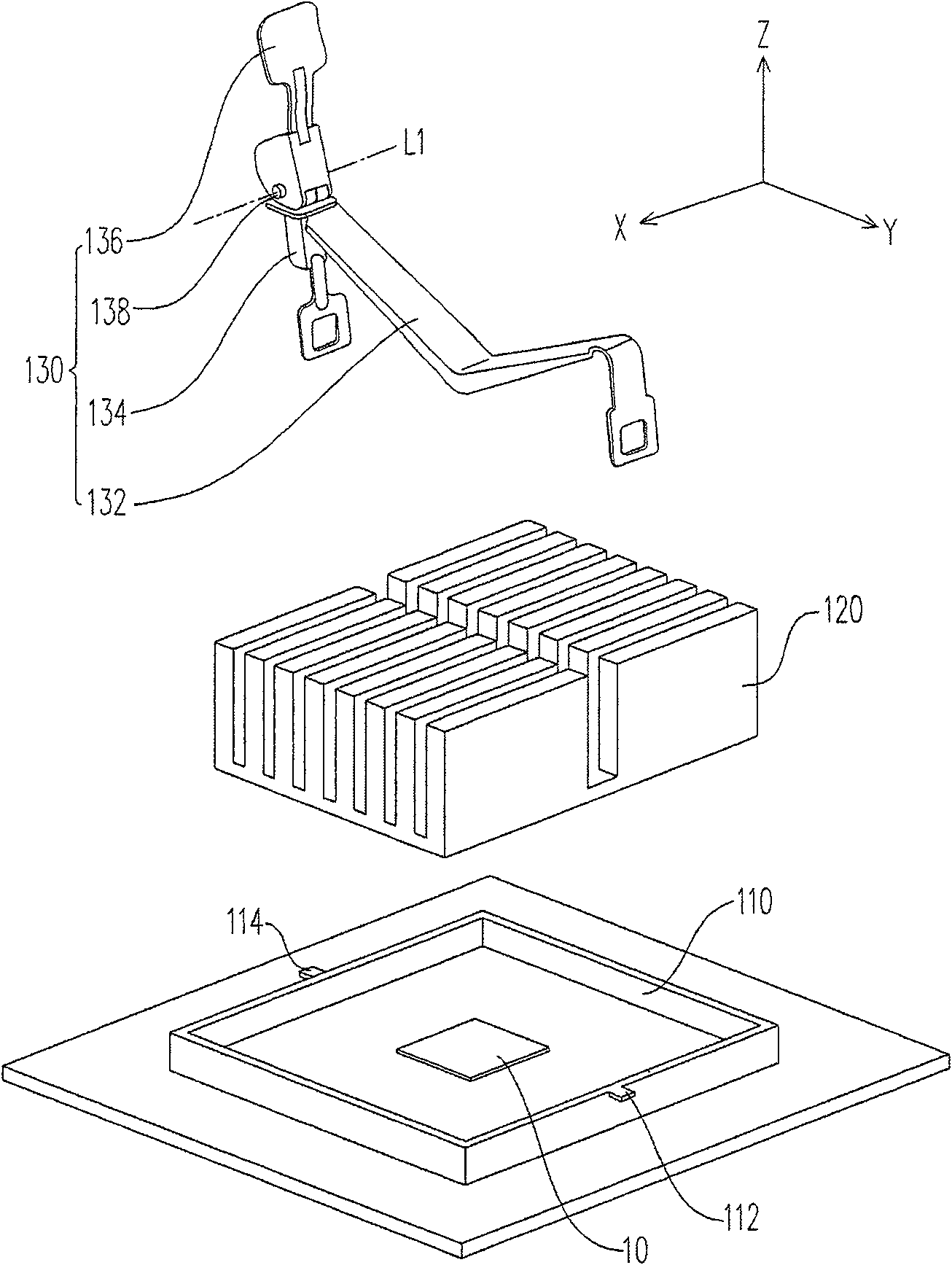

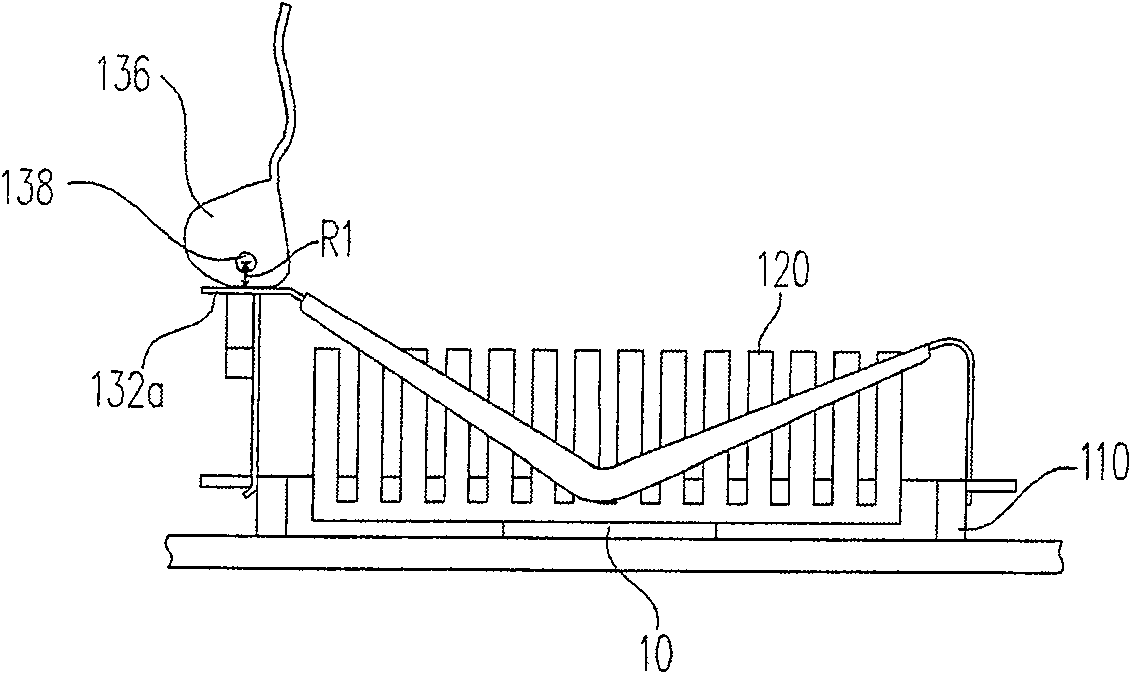

[0028] Figure 2A Is a three-dimensional view of a heat dissipation device arranged on a heat source according to a preferred embodiment of the present invention, and Figure 2B for Figure 2A Exploded view of the heat sink and heat source. Please also refer to Figure 2A versus Figure 2B The heat dissipation structure 200 of this embodiment is suitable for dissipating a heat source 22 on a circuit board 20. The heat dissipation structure 200 includes a fixing module 210, a heat sink 220 disposed on the heat source 22, and a fastener module 230.

[0029]In this embodiment, the fixing module 210 is disposed on the circuit board 20 and surrounds the heat source 22, and the fixing module 210 has a first buckling portion 212 and a second buckling portion 214. In addition, the radiator 220 is, for example, an extruded radiator or other appropriate type of radiator, and the fastener module 230 is spanned across the radiator 220 and is fastened to the first fastening portion 212 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com