Novel precision grinding polishers

A polishing machine, a precise technology, applied in the direction of surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of easy grinding of samples, hand-held loading blocks, and difficult precise control of grinding volume, etc., to achieve Improve utilization rate, ensure parallelism and improve polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

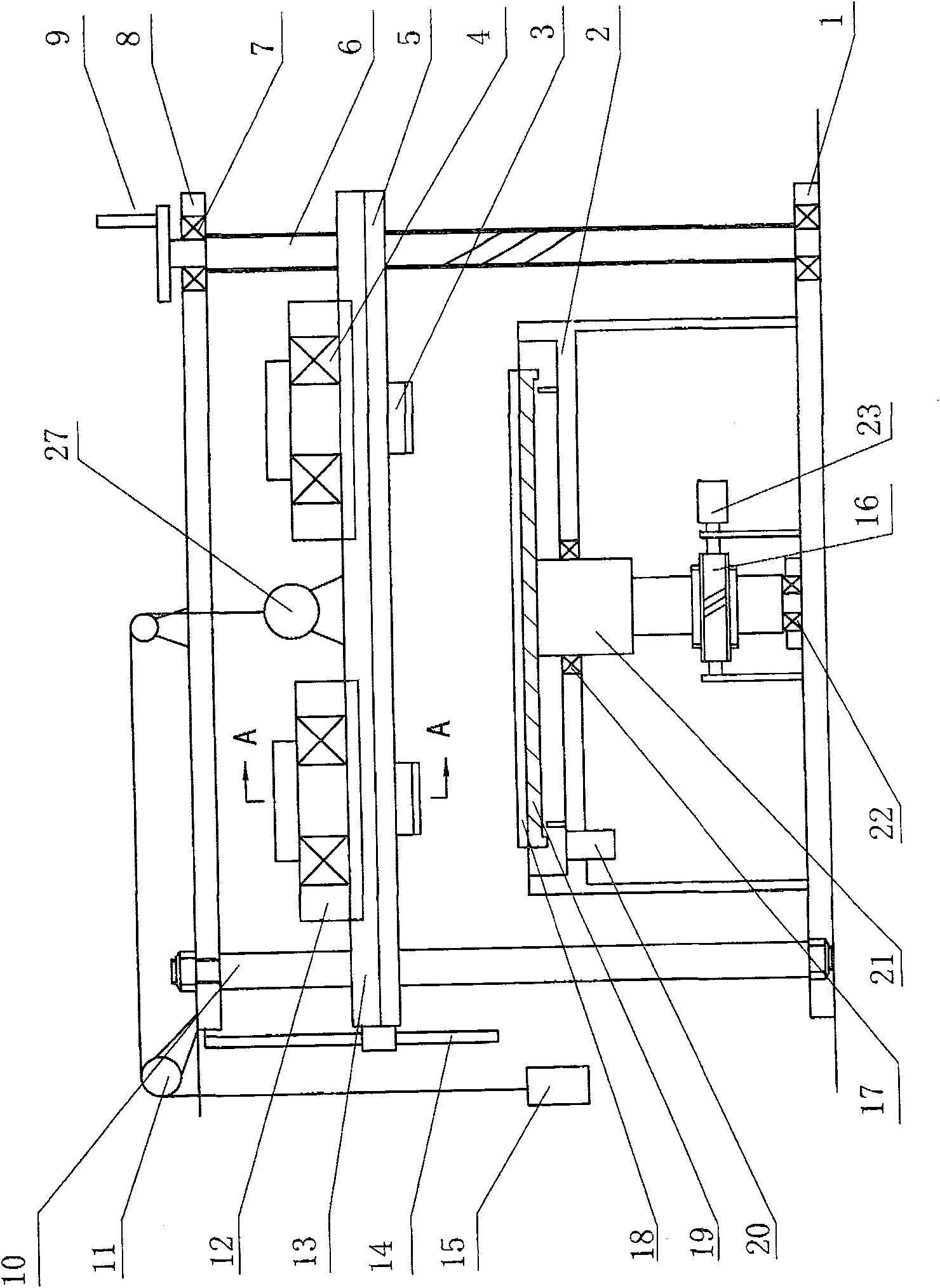

[0019] exist Figure 1-3 In the shown embodiment: the main shaft 21 is vertically installed between the frame 2 and the base 1 through the bearing 17 and the bearing 22, the upper end is bonded to the polishing disc 19, and the lower end is bonded to the turbine of the worm reducer 16, and the worm reducer The input end worm of device 16 is connected with motor 23 output shaft through shaft coupling. The motor 23 and the worm gear reducer 16 are all fixed on the base 1 by bolts.

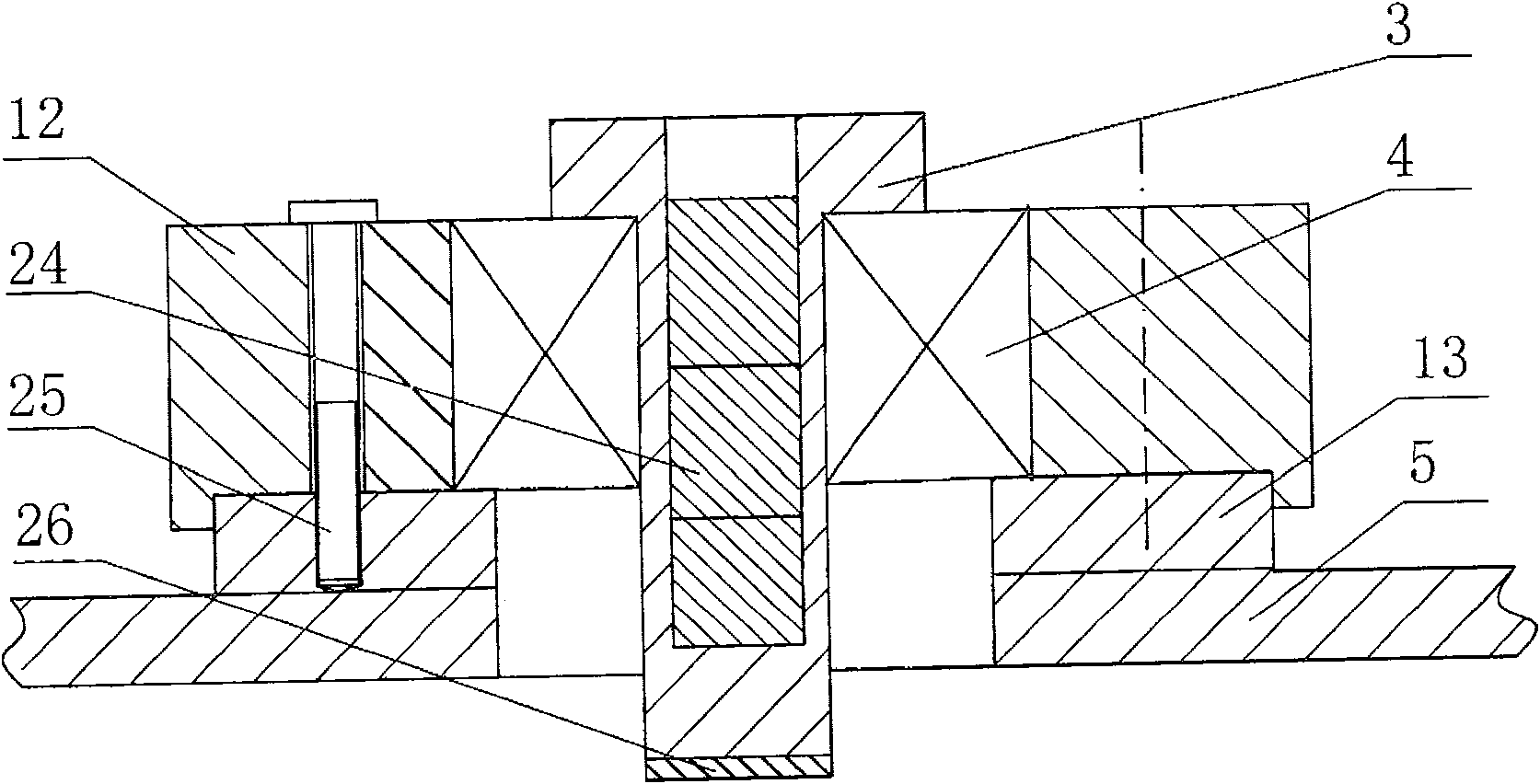

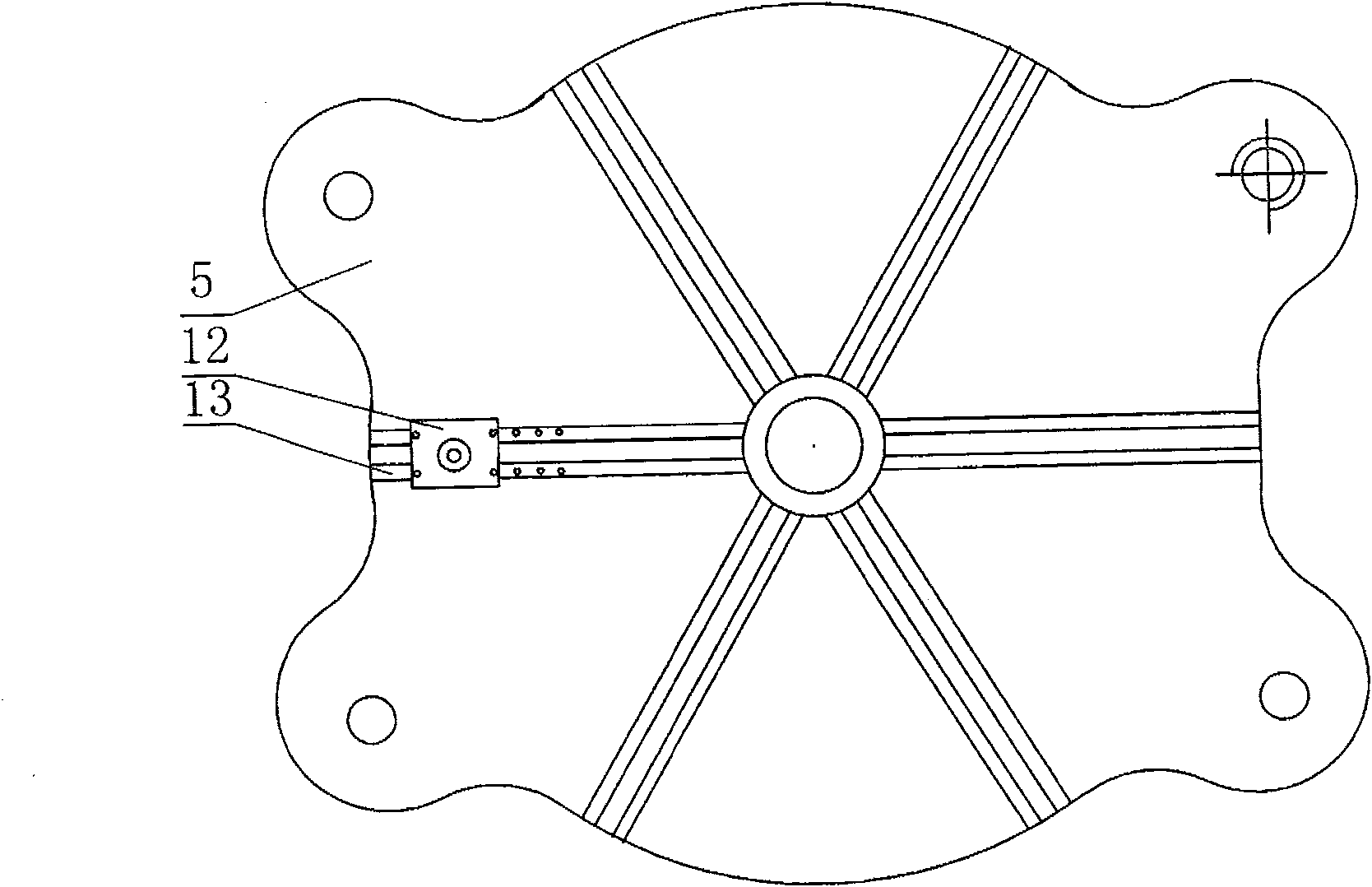

[0020] The precision lead screw 6 is vertically installed between the top plate 8 and the base 1 through the first bearing 7, and the upper and lower ends of the guide column 10 are respectively fixedly connected with the top plate 8 and the base 1 by bolts and kept parallel to the precision lead screw 6 . The middle plate 5 is installed between the top plate 8 and the base 1 and is positioned above the polishing plate 19. Its through hole is in clearance fit with the guide post 10, and its threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com