Near dry cutting liquid supply apparatus

A quasi-dry cutting and fluid supply technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., to achieve the effect of simple production, convenient operation and less resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

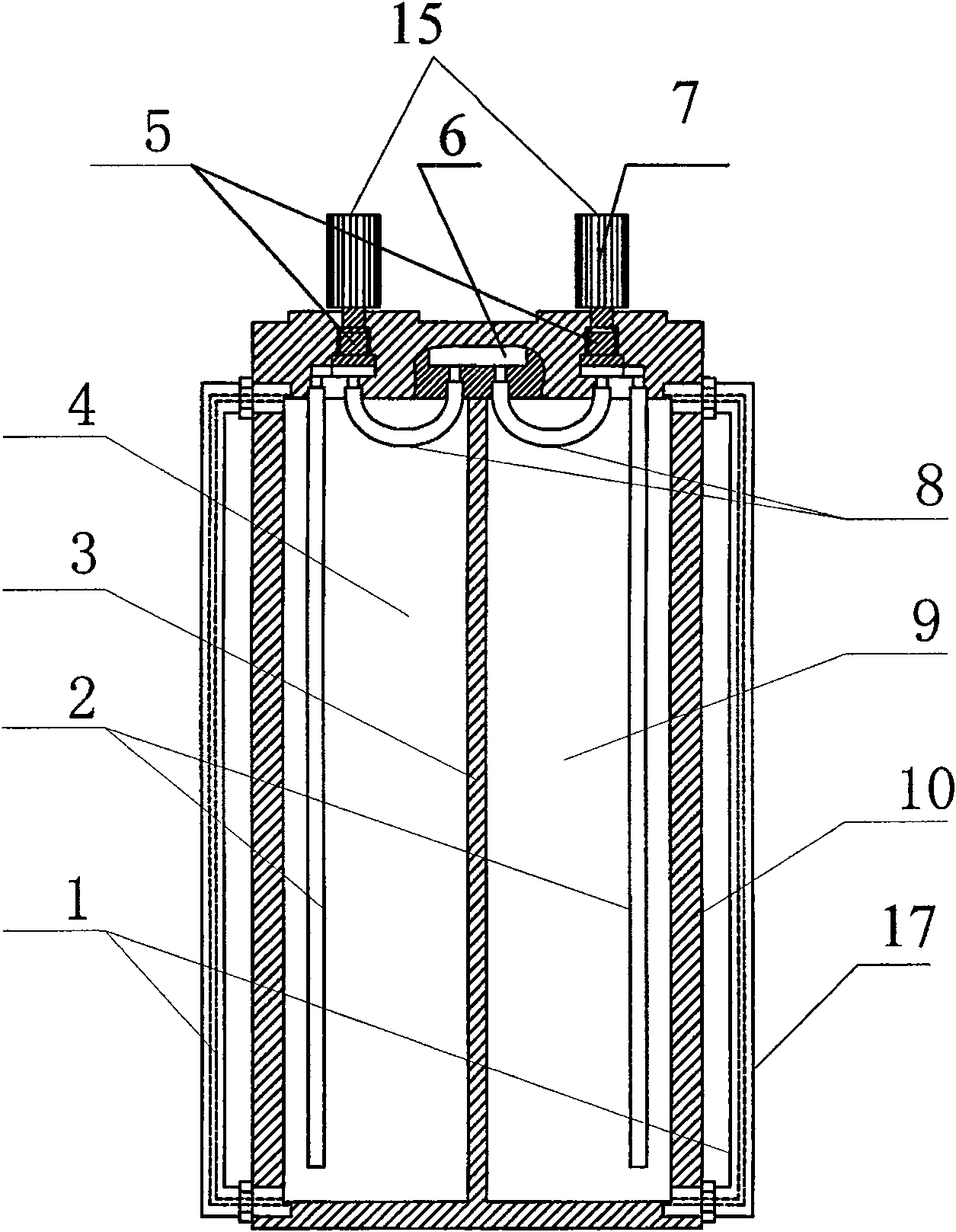

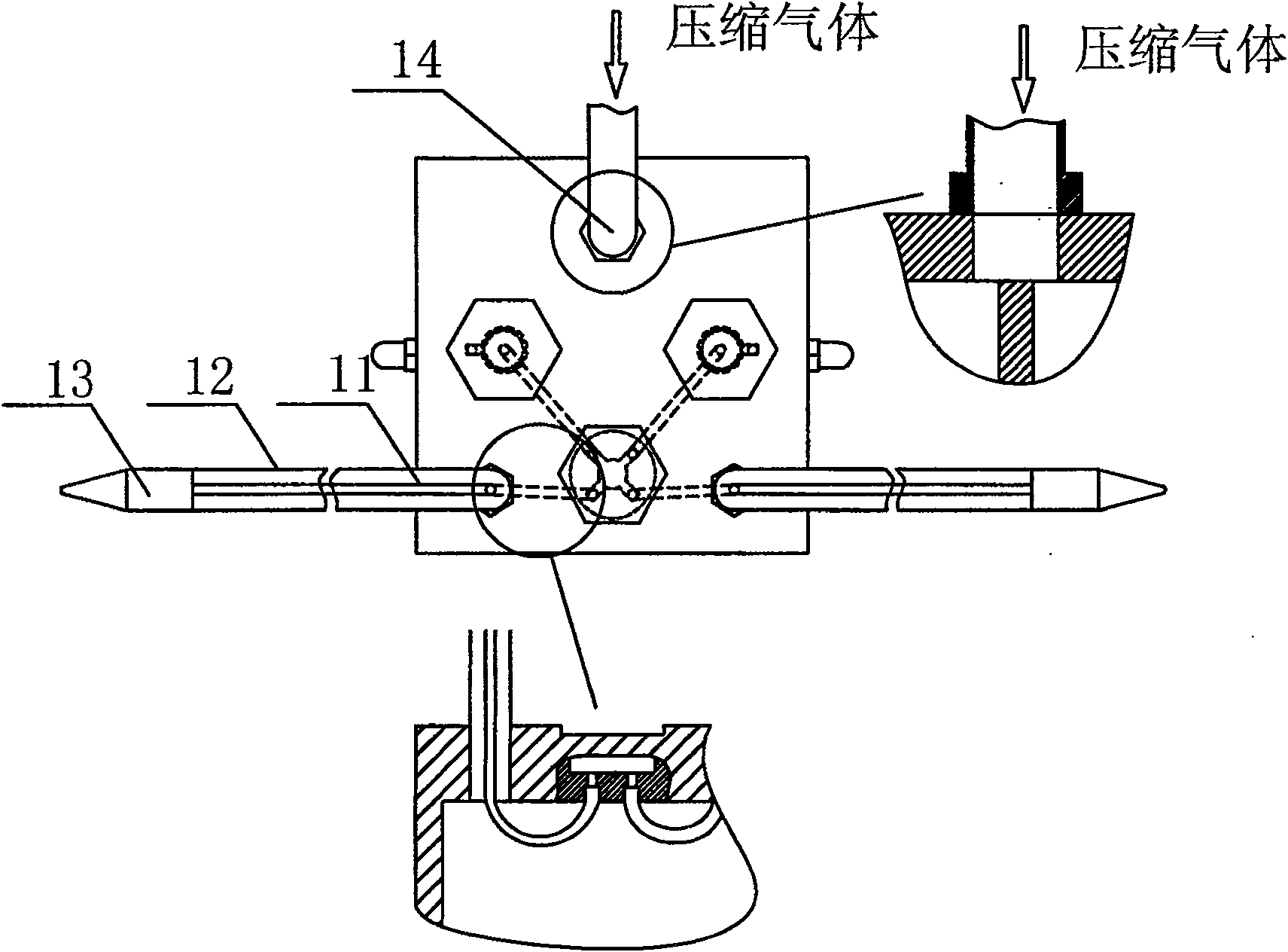

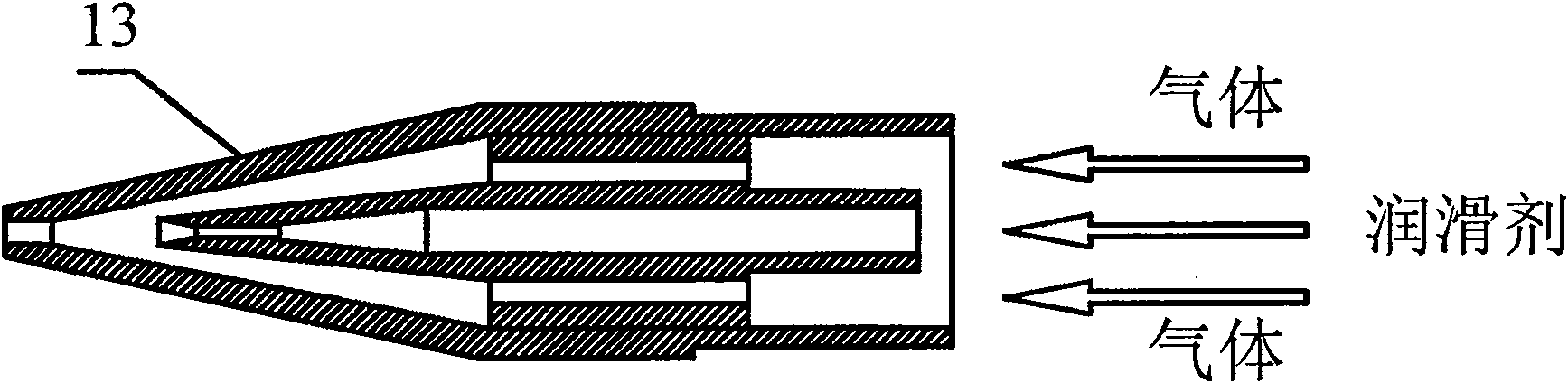

[0028] A quasi-dry cutting liquid supply device of the present invention, please refer to figure 1 , figure 2 , which includes a chamber wall 10, a chamber, a partition 3, a regulating valve 15, a mixing chamber 6, a catheter tube 8, a fluid guide tube 2, an inner tube 11, an outer tube 12, a compressed gas inlet 14 and a nozzle 13. The cavity wall 10 and the cavity form a hollow closed cavity 17; the partition plate 3 is placed in the cavity, and the cavity is divided into two compartments, namely, a first cavity 4 and a second cavity 9; There are two regulating valves 15, which are screwed to the top of the cavity to adjust the flow of lubricant or gas; the mixing cavity 6 is located at the top of the cavity 17, and is used to mix different lubricants or gases with lubricant; The liquid introduction pipes 2 are respectively placed inside the first chamber 4 and the second chamber 9, and one end thereof is connected with the regulating valve 15 for guiding the lubricant int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com