Lubricating system with trace amount

A micro-lubrication, threaded connection technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., to achieve the effect of less consumables, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

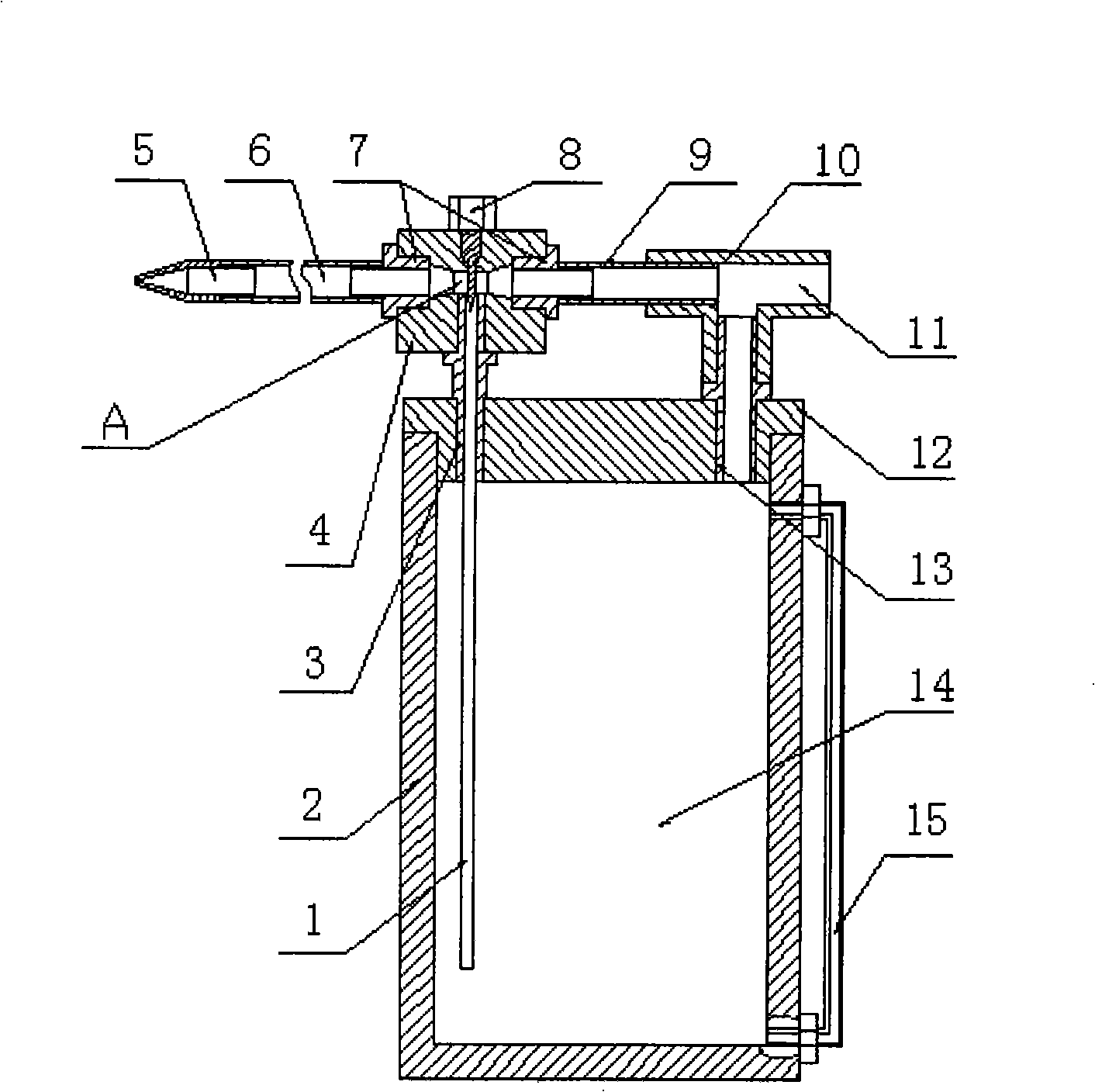

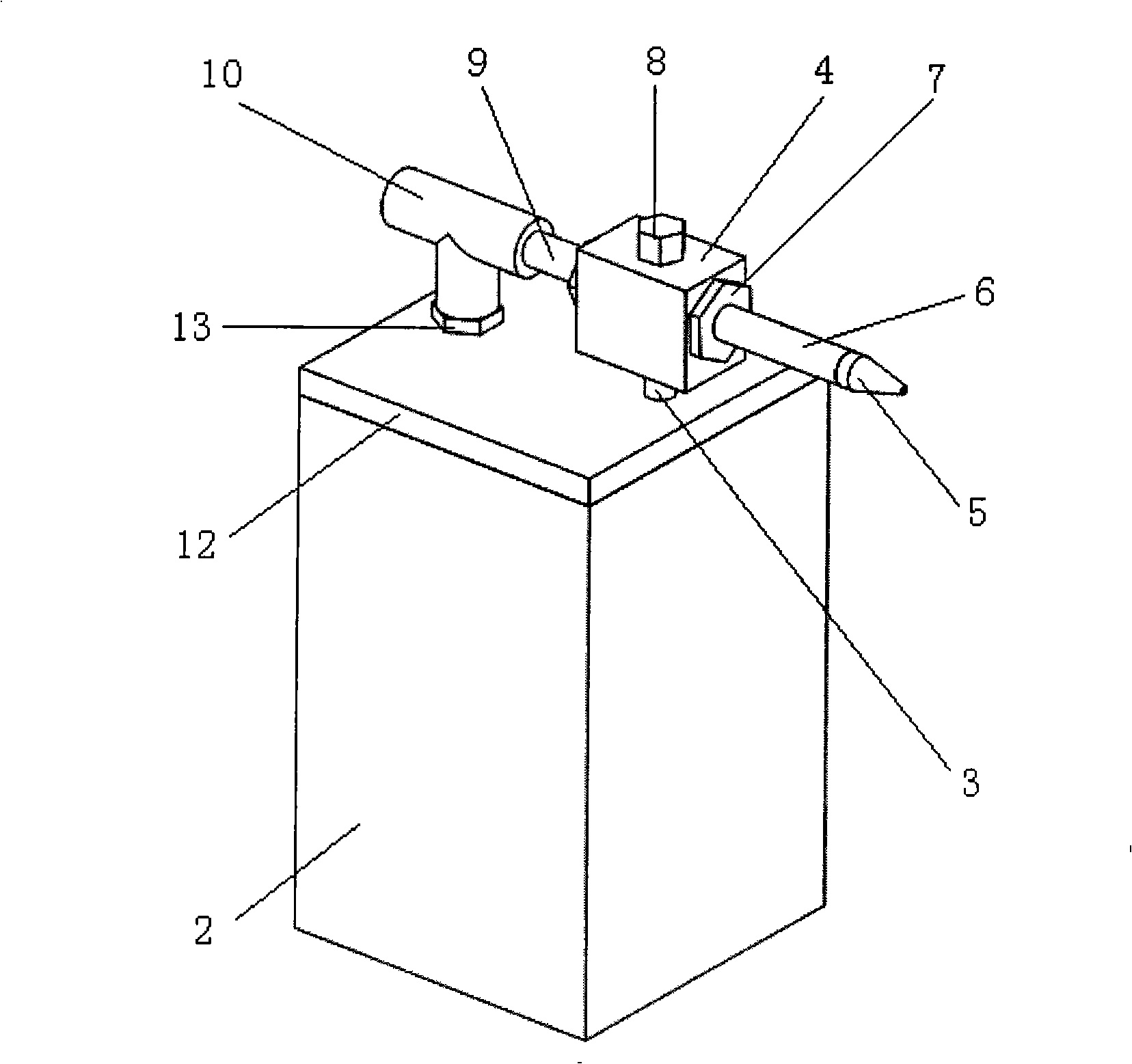

[0029] The working mode of the device of the present invention is introduced in detail below through a specific embodiment:

[0030] A kind of minimum quantity lubrication system of the present invention, such as figure 1 , image 3 As shown, the system consists of a cavity wall 2, an upper cover 12, a fluid guiding hose 1, a large threaded connecting column 13, a liquid suction device 4, a casing 9, a small threaded connecting column 3, a tee pipe 10, and a flow regulating valve 8 , transfer pipe 6 and nozzle 5.

[0031] The cavity wall 2 and the upper cover 12 form a hollow and closed cavity 14, and their junctions are provided with threaded holes, which are connected by screws.

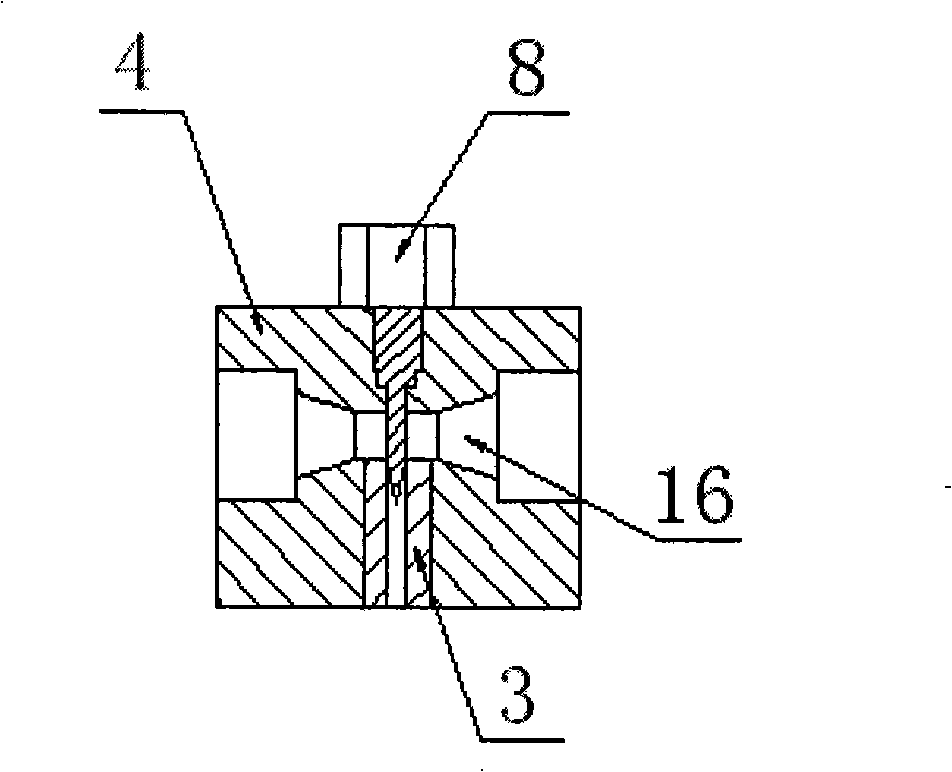

[0032] The liquid guiding hose 1 passes through the central hole of the small thread connecting column 3 and is glued to the inner wall of the small thread connecting column 3 , and one end thereof is located at the circumferential wall in the through hole of the liquid suction device 4 . For in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com