Manufacturing technology for carbon tube of bamboo composite material wind-driven generator blade

A technology of wind power generators and composite materials, applied in the direction of tubular objects, household components, applications, etc., which can solve the problems of the mechanism of destroying materials, the inability to meet the surface accuracy of products, external dimensions and performance, etc., to achieve low manufacturing costs and meet strength , The effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

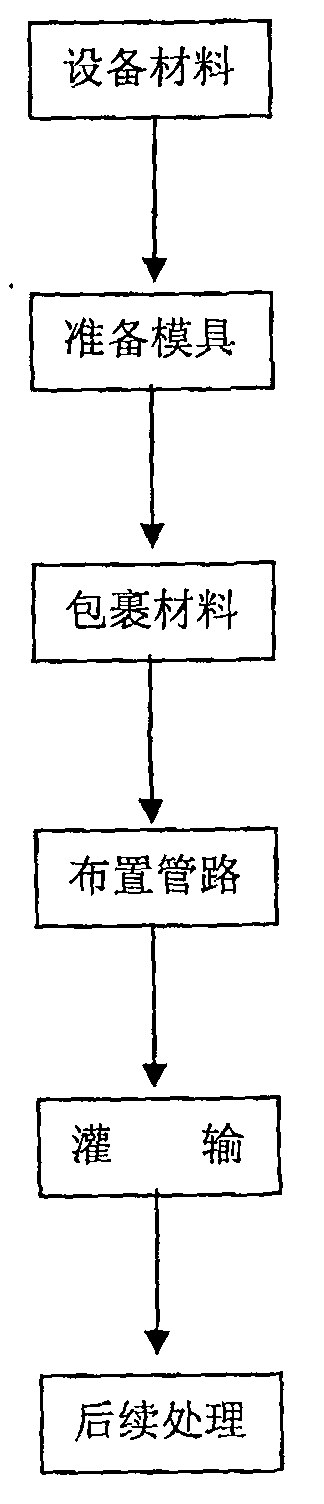

[0034] The manufacturing process of the carbon tube in the bamboo composite wind generator blade of the present invention adopts the following process steps:

[0035] 1. Equipment and material preparation:

[0036] According to the conventional infusion process, the required size and shape of carbon tubes are equipped with moulds, vacuum pumps, air compressors, and vacuum gas storage tanks; materials: carbon fiber cloth, matrix materials and various paving materials are used for organic materials.

[0037] 2. Prepare the mold:

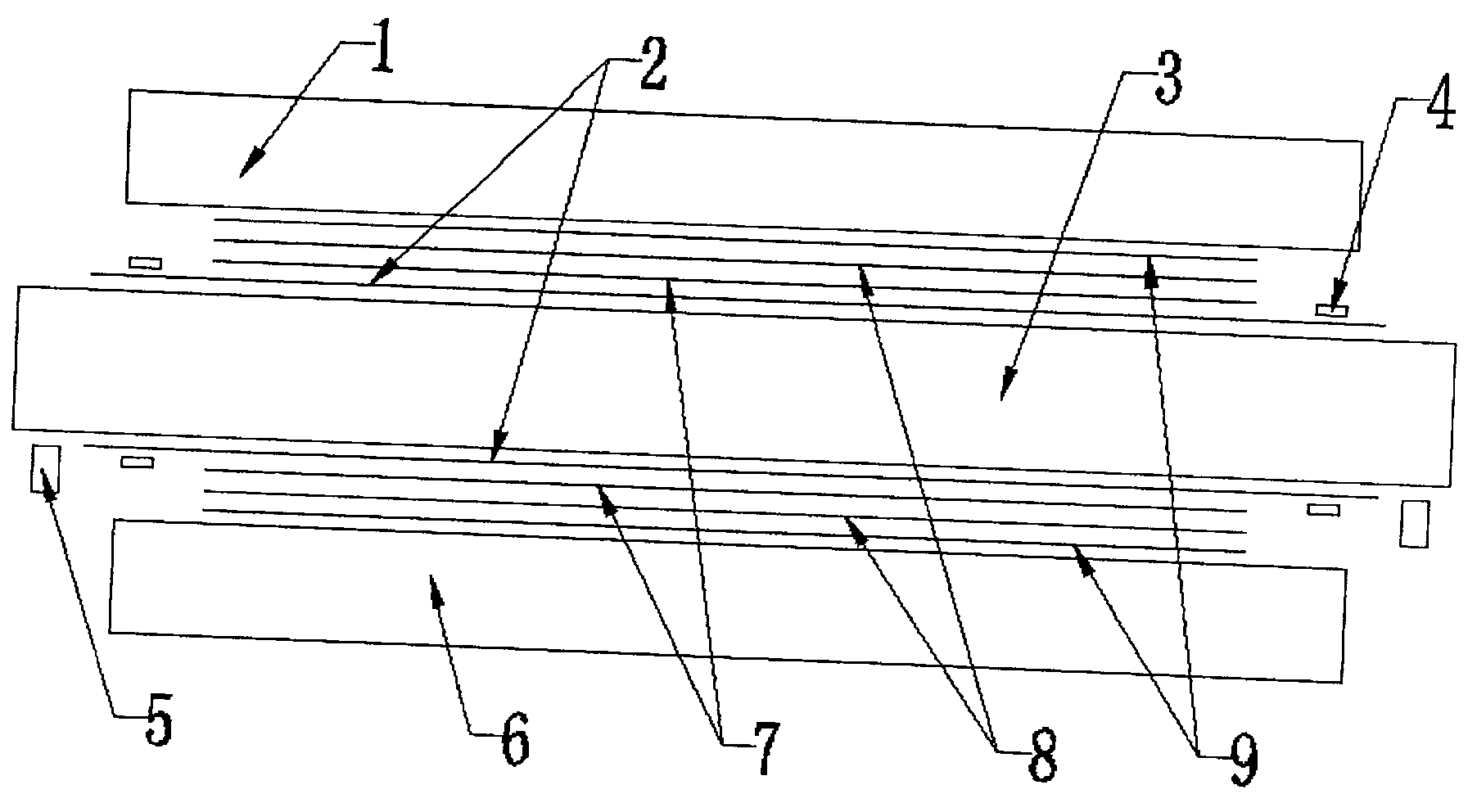

[0038] (a), prepare the mandrel 3 and the upper and lower female molds 1, 6; first remove the impurities on the surface of the mandrel 3, so that the surface of the entire mandrel 3 is smooth; clean the upper and lower female molds 1, 6, and wipe the mold cleaner on the surface , Release agent.

[0039] (b), fix the mandrel 3: wrap the sealing material 2 with silicone liquid and wrap it outside the mandrel 3. After the liquid silica gel is cured, a l...

Embodiment 2

[0051] The manufacturing process of the carbon tube in the bamboo composite wind generator blade of the present invention adopts the following process steps:

[0052] 1. Equipment and material preparation:

[0053] According to the conventional infusion process, the required size and shape of carbon tubes are equipped with moulds, vacuum pumps, air compressors, and vacuum gas storage tanks; materials: carbon fiber cloth, matrix materials and various paving materials are used for organic materials.

[0054] 2. Prepare the mold:

[0055] (a), prepare the mandrel 3 and the upper and lower female molds 1, 6; first remove the impurities on the surface of the mandrel 3, so that the surface of the entire mandrel 3 is smooth; clean the upper and lower female molds 1, 6, and wipe the mold cleaner on the surface , Release agent.

[0056] (b), fix the mandrel 3: wrap the sealing material 2 with a silicone belt outside the mandrel 3 (tightly sleeve the outside of the mandrel) and then c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com