Method and preheating control apparatus of compressor

A preheating control and compressor technology, applied in engine control, AC motor control, pump control, etc., can solve problems such as compressor temperature error, difficulty in performing compressor preheating control, and inability to correctly estimate motor coil resistance, etc., to achieve Effects of eliminating voltage errors and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

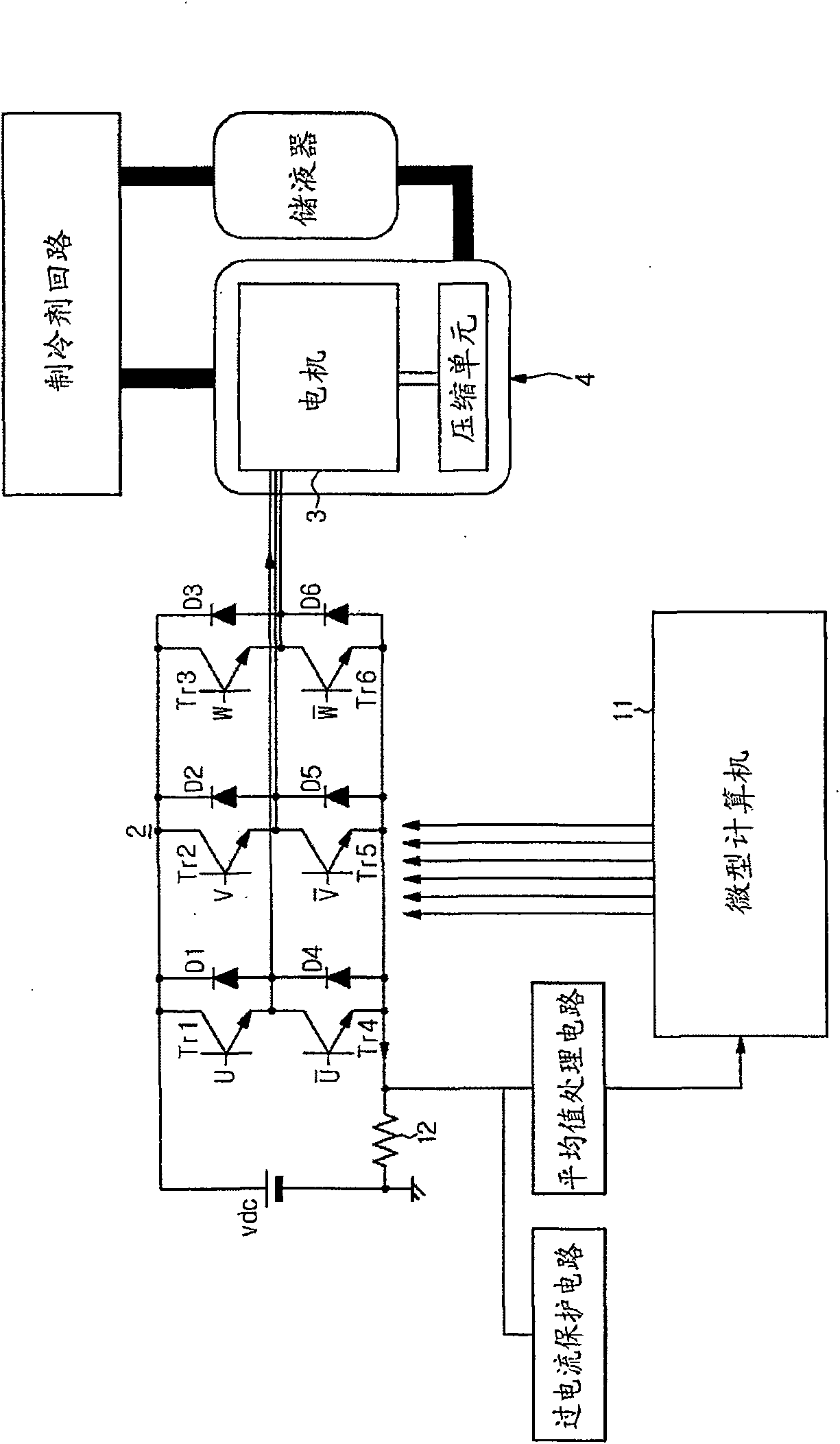

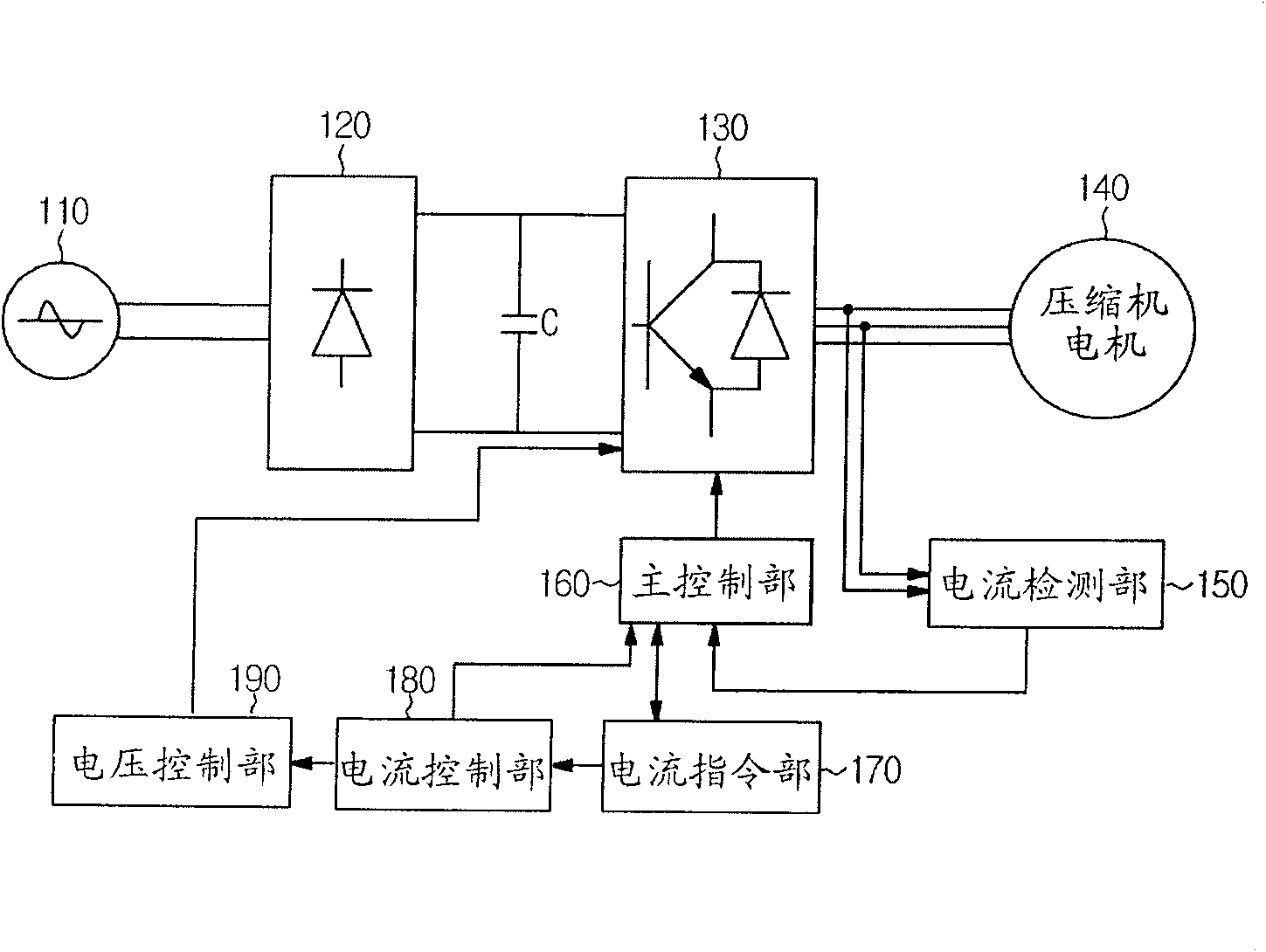

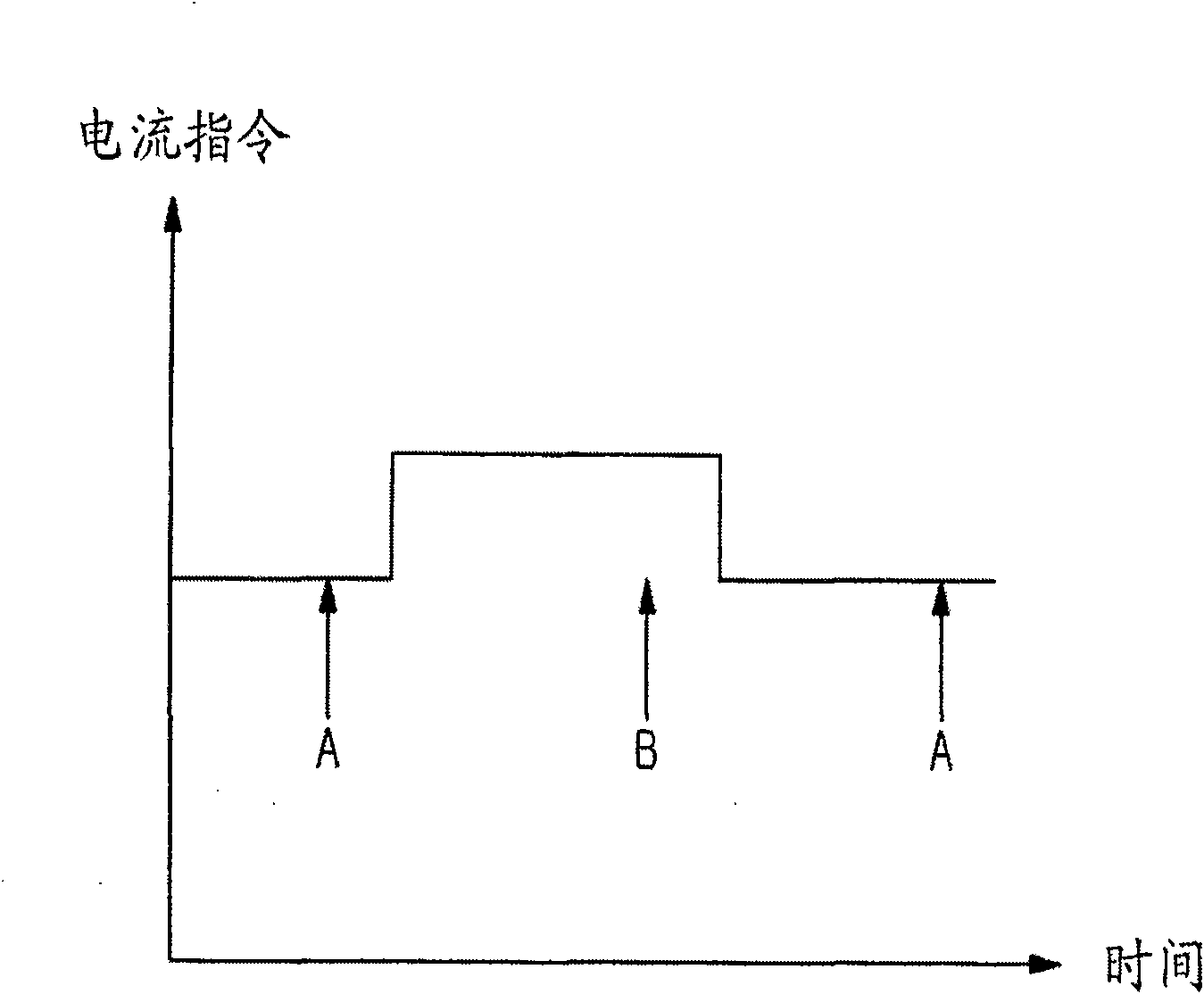

[0022] figure 2 It is a structural diagram of the drive system of the compressor motor provided according to the embodiment of the present invention. The rectifier unit 120, the inverter 130, the compressor motor 140, the current detection unit 150, the main control unit 160, the current command unit 170, and the current control unit The unit 180 and the voltage control unit 190 are constituted.

[0023] The rectifier 120 rectifies the alternating current (AC) power source 110 to generate a direct current power source, and the rectified direct current power source is smoothed by a capacitor (C) to supply a direct current (DC) power source.

[0024] The inverter 130 converts the DC power supplied by the rectifier unit 120 into a three-phase AC power (U, V, W) in the form of pulses having an arbitrary variable frequency and supplies it t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com