Radial tyre injection type vulcanizing capsule mold

A radial tire, curing bladder technology, applied in tires, household appliances, other household appliances and other directions, can solve the problems of unsatisfactory work performance, low product yield, complex glue injection, etc., to improve steam utilization efficiency, reduce costs, The effect of convenient glue injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

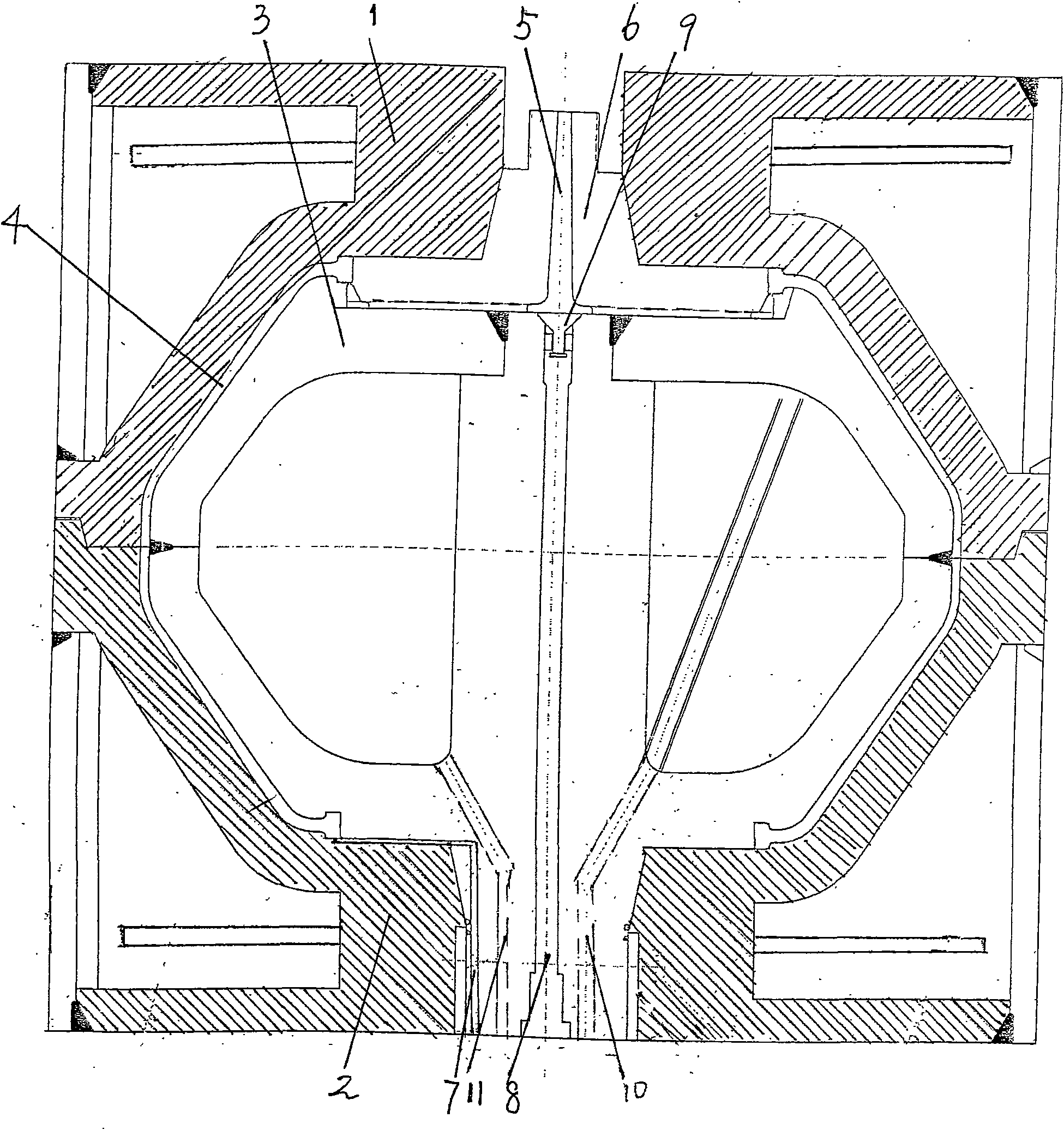

[0011] An injection type vulcanization bladder mold for a radial tire, comprising an upper mold 1, a lower mold 2, and a core mold 3, in the core mold cover 6 (or in the upper mold) above the mold cavity 4 formed by the upper mold, the lower mold and the core mold , the injection hole 5 communicating with the inner cavity of the mold is set, and the vacuum passage 7 communicating with the inner cavity of the mold is set under the inner cavity of the mold.

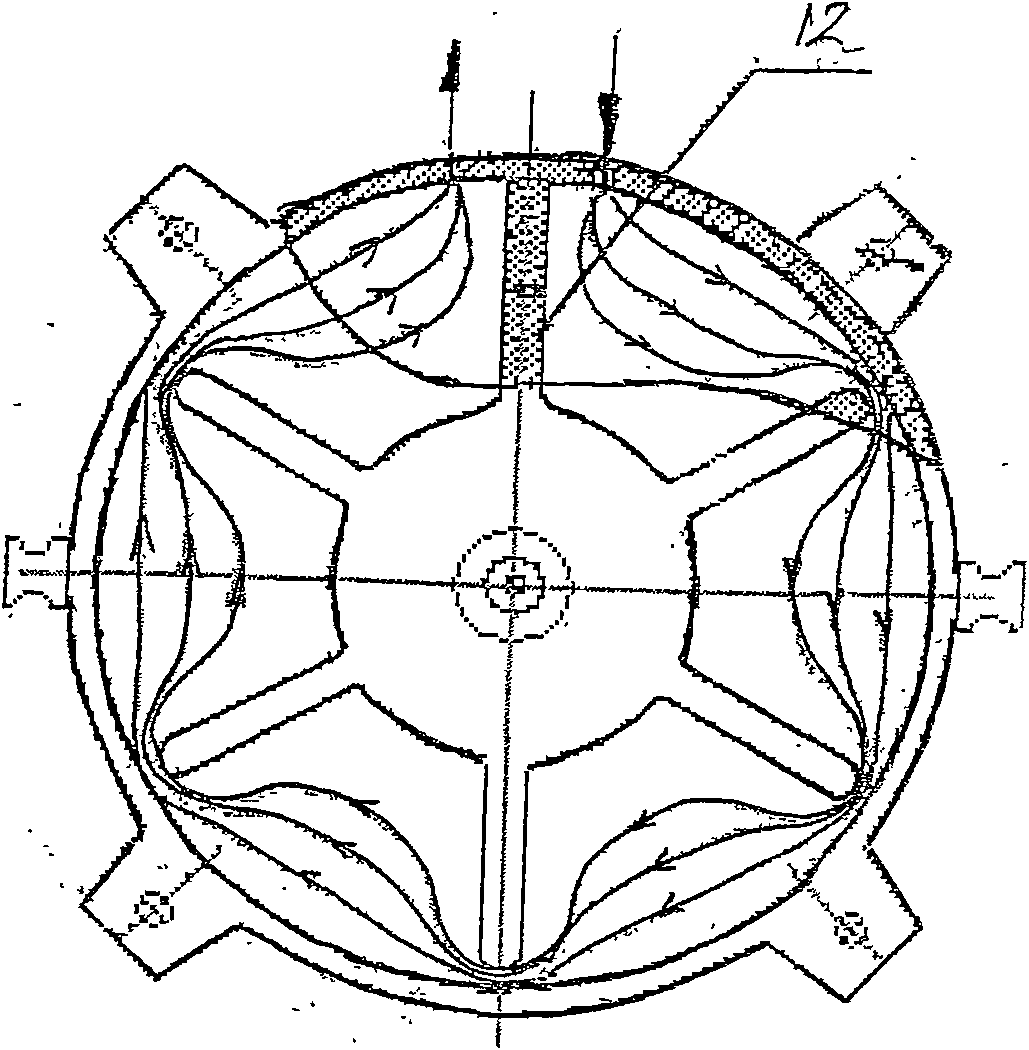

[0012] A gas channel 8 is arranged in the middle of the mandrel, and the gas channel communicates with the outer surface of the mandrel through an air valve 9, and can be demolded by gas. The inner cavity of the core mold communicates with the inlet and outlet pipes 10 and 11 of the heating medium. The outer cavities of the upper and lower molds are provided with flow-guiding partitions 12 for the heat-conducting medium. There are multiple diversion partitions arranged radially. Mold surface accuracy ≤0.05mm, concentricit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com