Synchronous hinge head and assembly method

A technology of hinged joints and outer parts, which is applied in the field of synchronous hinged joints and assembly, can solve the problems of small ball contact angle, weakened cage, high manufacturing cost, etc., and achieve the effect of weight reduction, small turning diameter and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

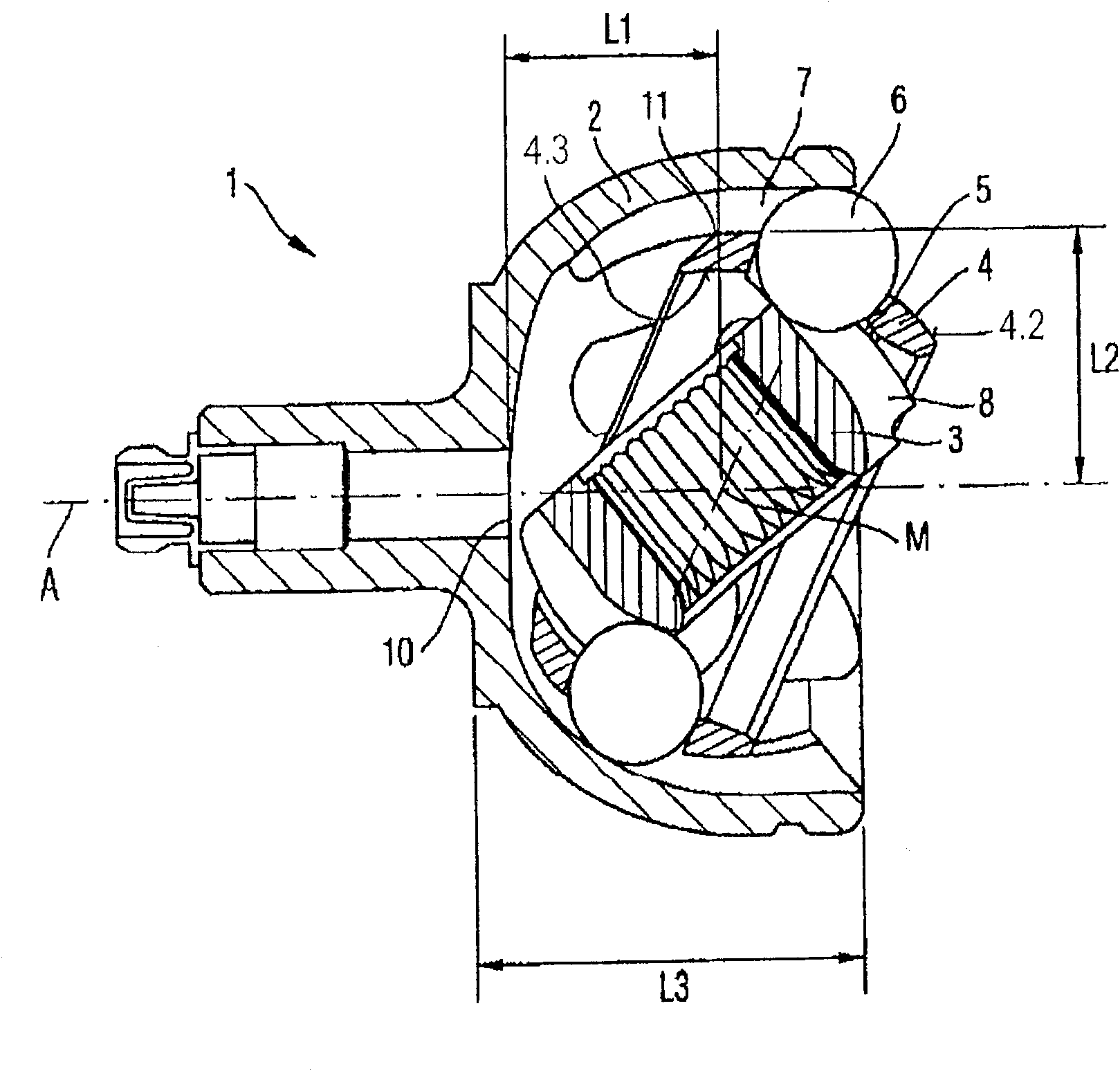

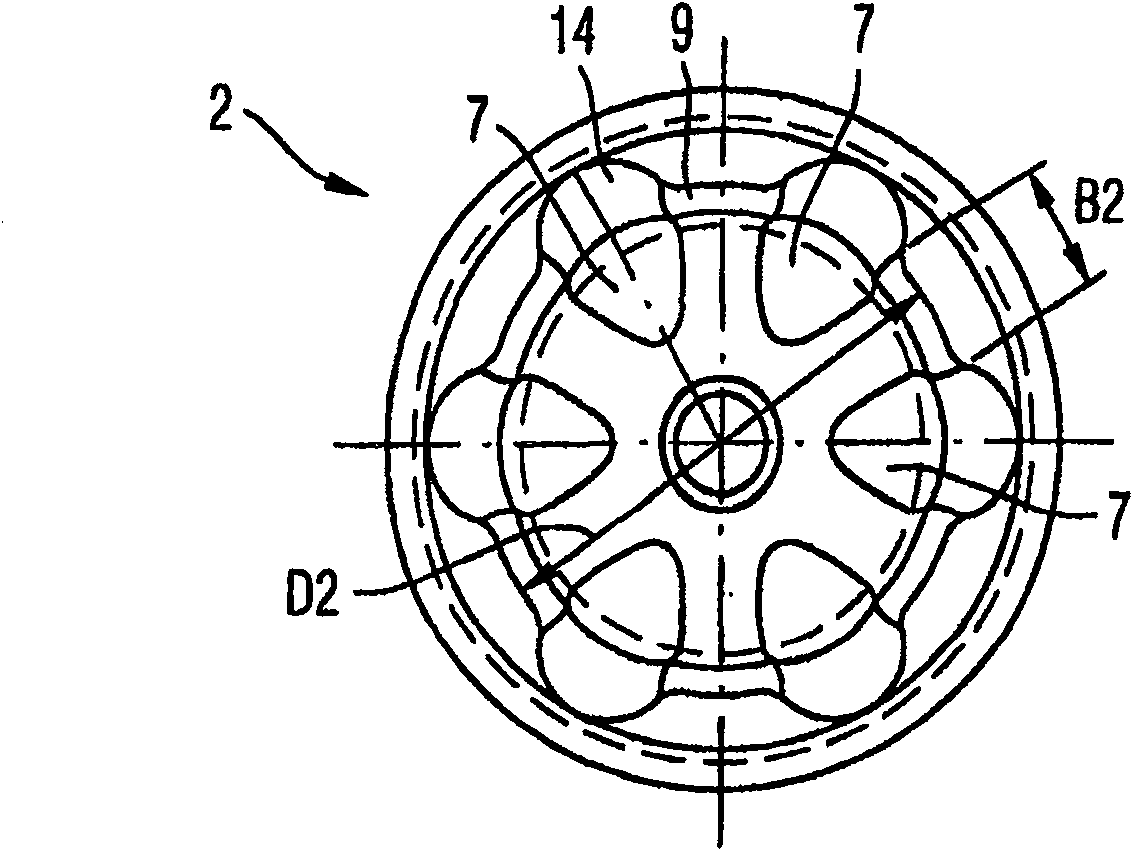

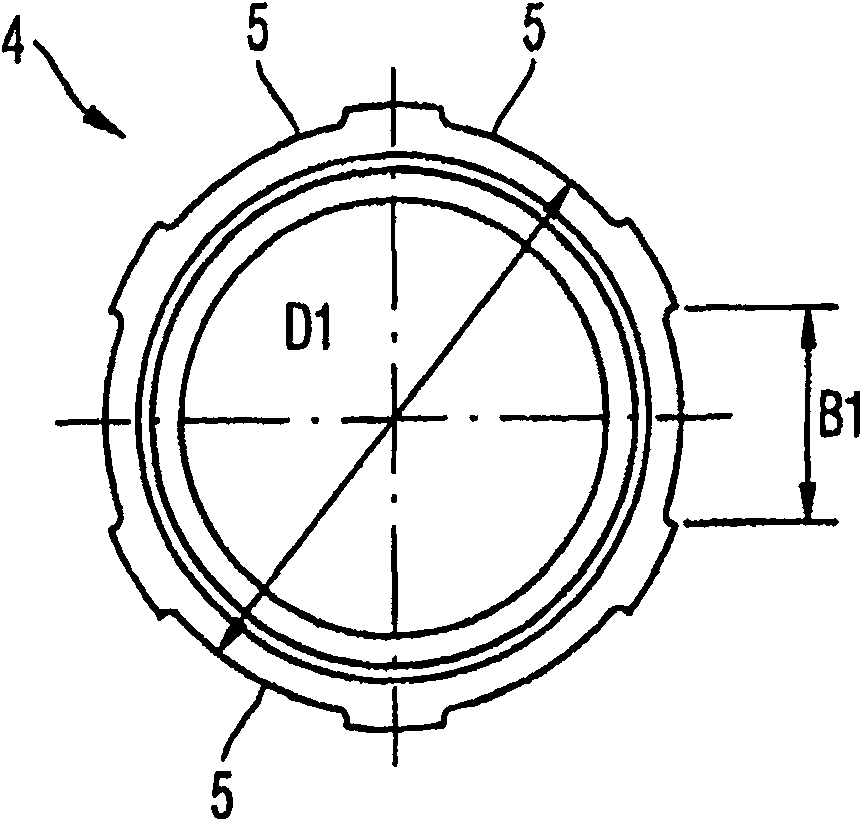

[0041] Figures 1 to 6 The first embodiment shown in shows a synchronous joint 1 for torque transmission with angular balance. The synchronous joint 1 comprises an outer part 2 of bell-shaped design shown here by way of example, an inner part 3 accommodated in the outer part and a cage 4 which can surround a center point M of rotation. It is held pivotally between the outer part 2 and the inner part 3 . For this purpose, spherically curved surfaces 4 . 2 and 4 . 3 are provided on the cage outside and cage inside, which can be slidably guided on corresponding wall sections of the outer part 2 and inner part 3 , respectively. The centers of curvature of the outer surface 4.2 and the inner surface 4.3 are located at the midpoint M of rotation. Although a small axial offset of the above-mentioned center of curvature is possible, such an eccentricity cannot be used to control the ball 6 in the half-angle plane. A plurality of windows 5 distributed in the circumferential directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com