Motorcycle frame with bent beam

A curved beam motorcycle and frame technology, which is applied to motorcycles, bicycle frames, motor vehicles, etc., can solve problems such as troubles, increased production cost investment, and loss of the compact characteristics of curved beam vehicles, achieving low cost, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

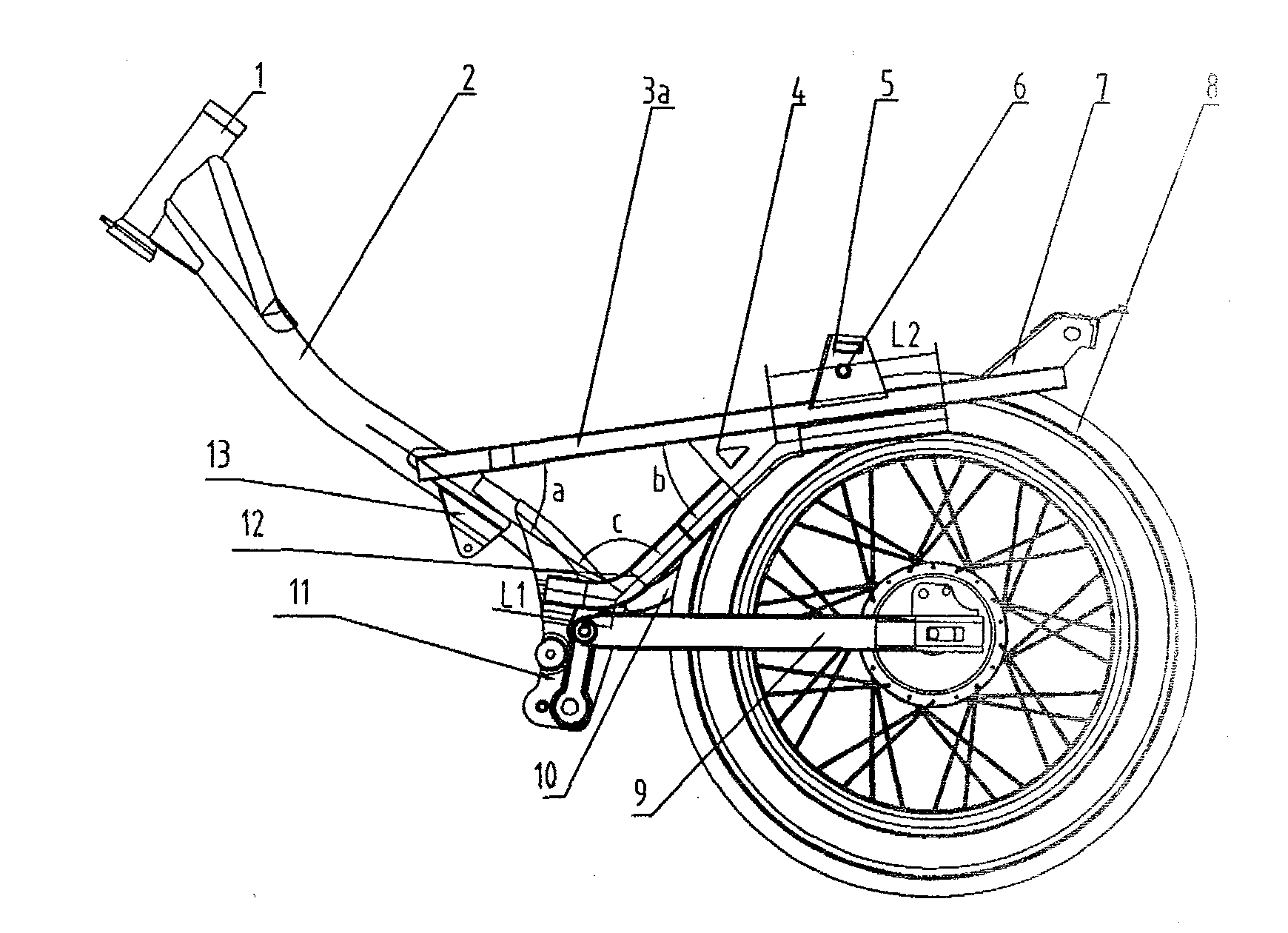

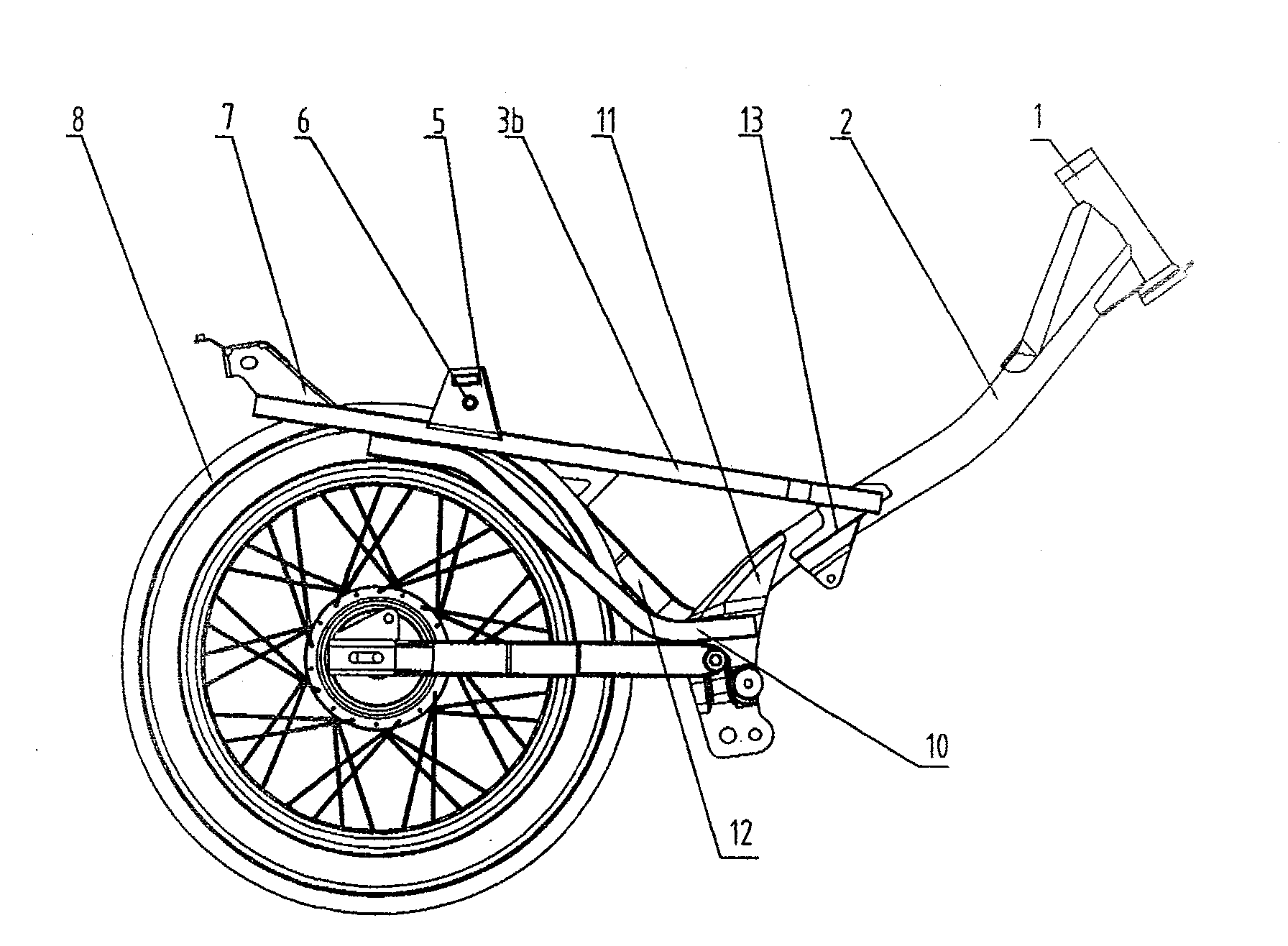

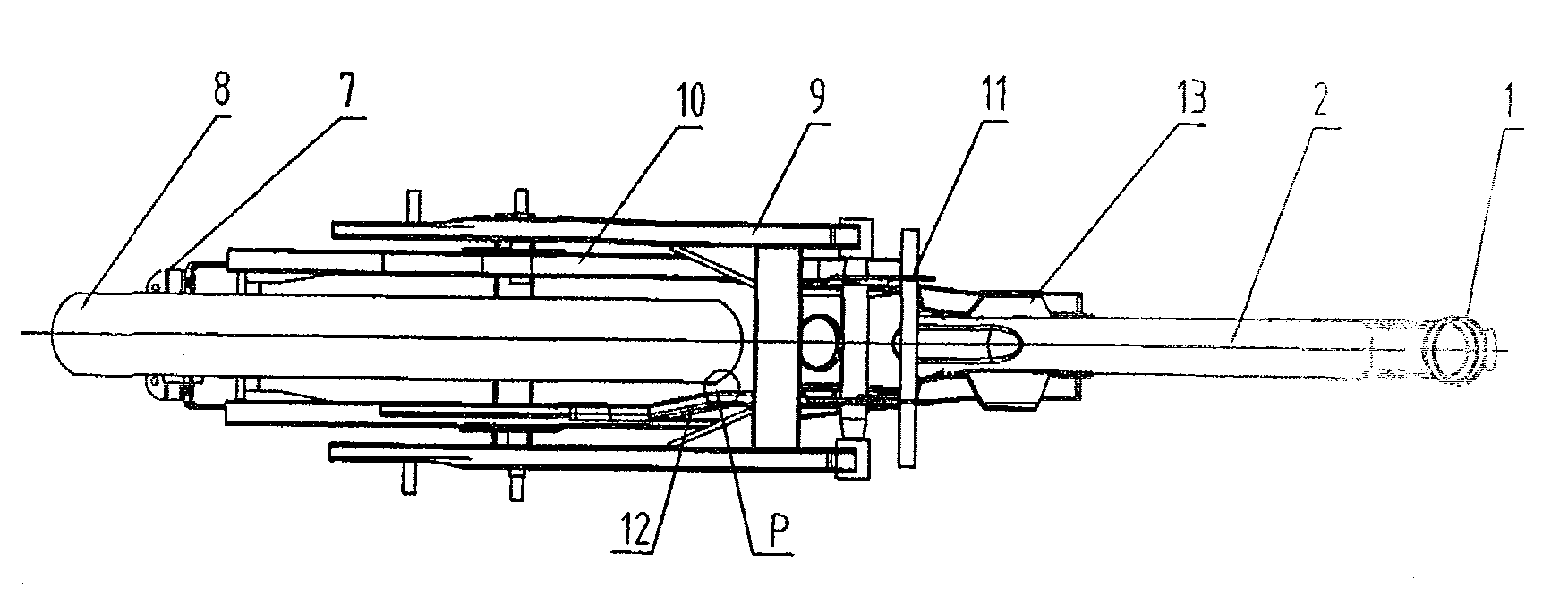

[0016] See Figure 1 to Figure 3 , The main beam tube 2 of the two-wheeled curved beam motorcycle frame of the present invention is high in the front and low in the back. The front end of the main beam tube 2 is welded with the head tube 1 and the rear end is welded with the suspension seat 11. The tailstock of the frame is low in the front and high in the rear. The rear damping support base 5 is welded on the tailstock. The rear damping support base 5 is fixedly provided with a shock absorber support shaft 6 for installing rear damping. The tail of the tailstock is welded with a taillight support tube 7 and two tailstocks. The front end of the longitudinal beam is welded to the middle section of the main beam tube 2. The angle a between the tailstock below the tailstock and the central axis of the main beam tube 2 is 40-42°. The main beam tube is welded with the engine near the welded tailstock. A front suspension bracket 13, which suspends the engine together with a suspensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com