Engine oil filter element

An oil filter and filter cartridge technology, applied in the installation/connection of lubricant purification devices, lubricating parts, pressure lubricants, etc., can solve the problems of reducing the filter area and increasing the filter area, to increase the filter area, increase The effect of filter area and flow increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

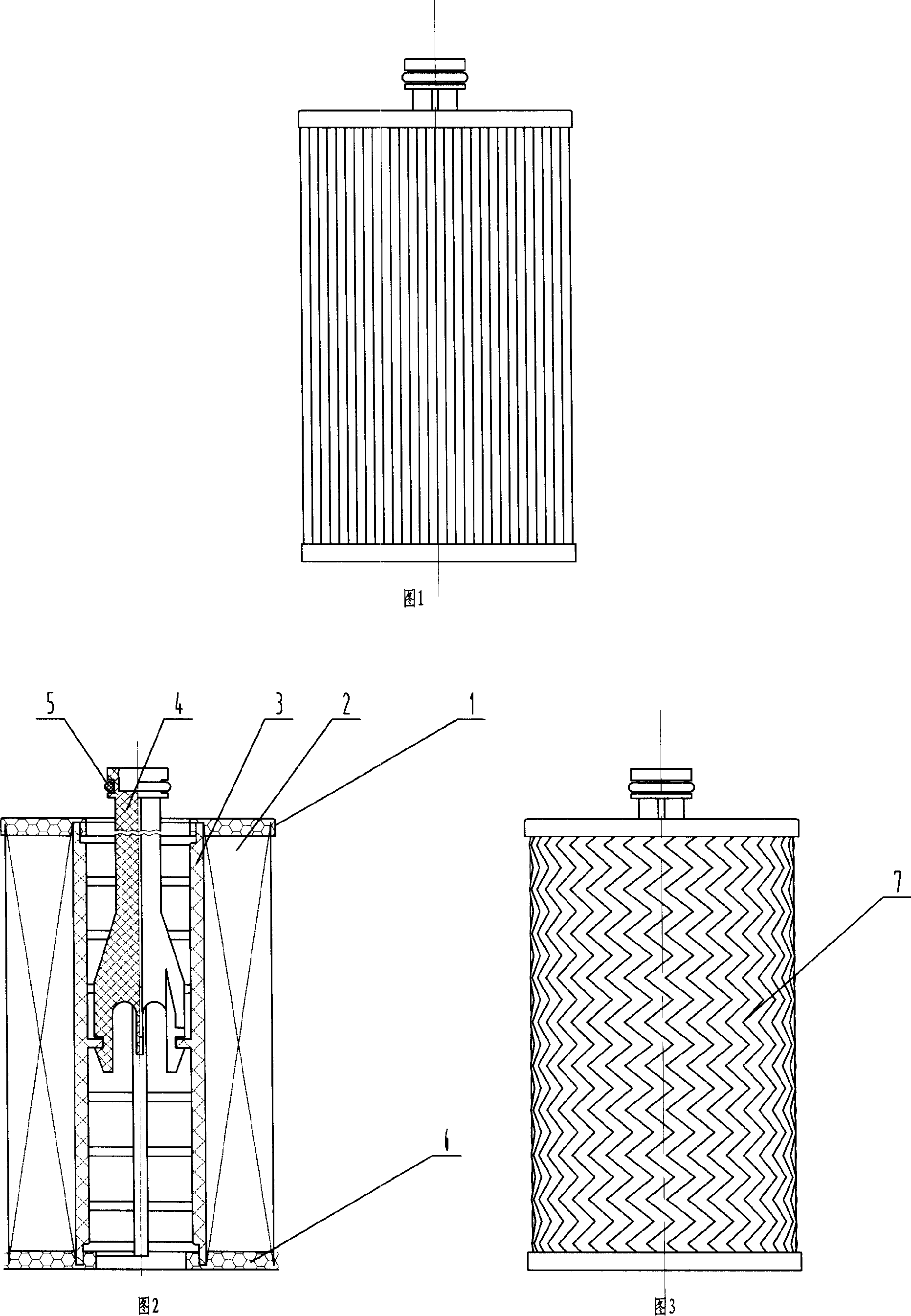

[0010] Referring to Fig. 1, the oil filter element includes upper and lower end caps 1, 6, a filter cartridge 2 and a central pipe 3, the filter cartridge 2 is formed by arranging filter paper into a number of wavy hinges 7 on the circumference of the central pipe 3, The upper and lower end caps 1, 6 are arranged at both ends of the filter cartridge 2, and the present invention adopts the upper and lower end caps 1, 6 of epoxy resin material to bond the central tube 3 and the filter cartridge 2 with an adhesive, so that the oil inlet of the filter element Separated from the oil outlet through the filter cartridge 2, the upper and lower end caps 1, 6 made of this epoxy resin material have increased the larger filter cartridge filtration area than the metal end cap. The center pipe 3 is used to support the filter cartridge 2 and increase the strength of the filter element. After the oil is filtered from the outer surface of the filter cartridge 2, the oil is discharged from the c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap