Booster compressor

A compressor, booster technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve problems such as poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

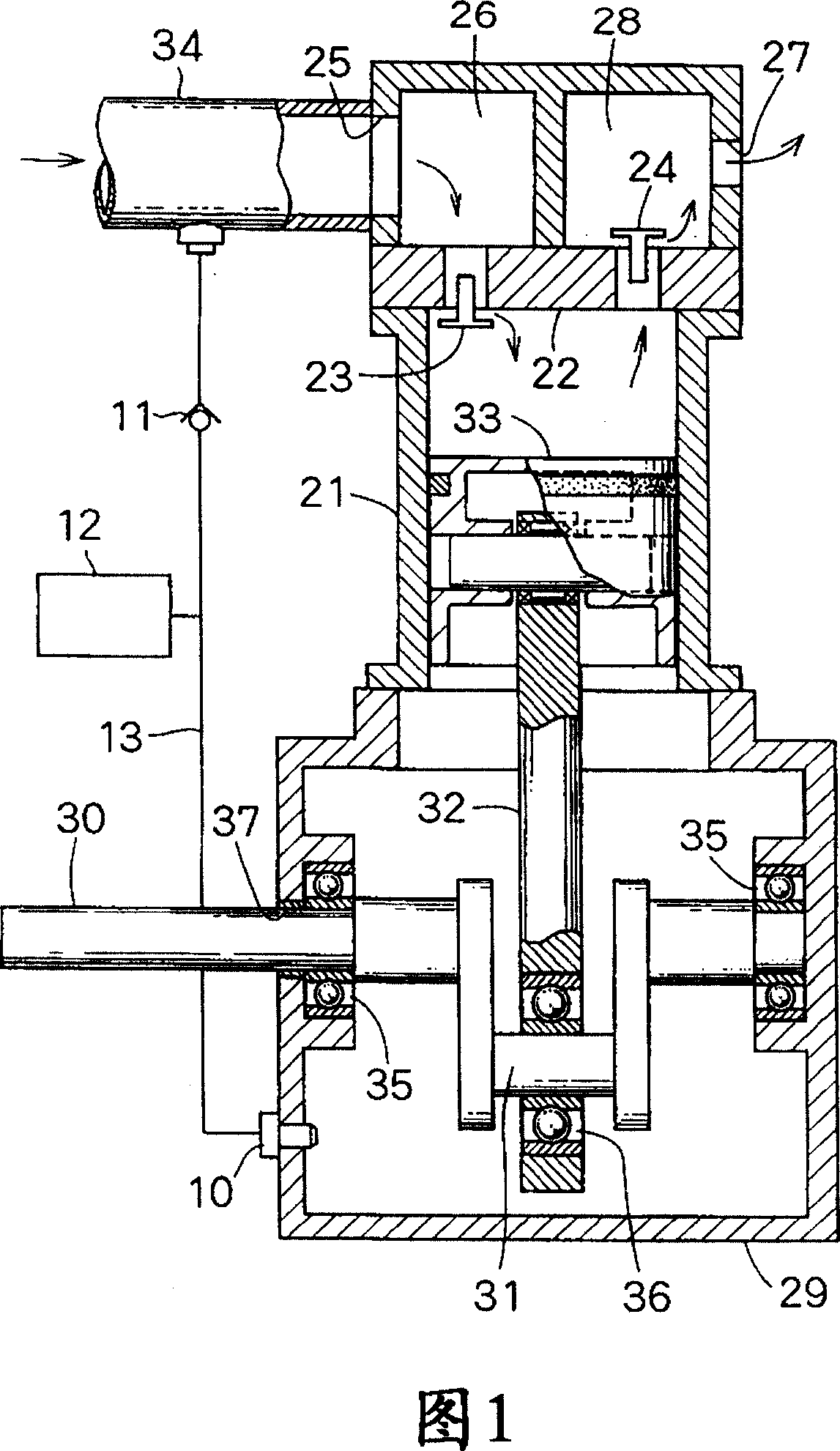

[0016] The basic structure of the booster compressor is not much different from that in Figure 4. The same reference numerals refer to the same elements as in FIG. 4 and descriptions thereof are omitted. Only the differences will be described below.

[0017] In FIG. 1 , the air holes 39 of FIG. 4 are absent. Instead, a compressed gas inlet 10 is formed. The compressed gas flow path 34 is connected to the compressed gas inlet 10 by a bypass pipe 13 comprising a check valve 11 and a pressure regulator 12 such as a pressure regulating valve or a pressure reducing valve, the check valve 11 facing the compressed gas flow path 34 closes and opens in the opposite direction.

[0018] When the compressed gas is supplied to the suction chamber 26 by opening a valve (not shown), the compressed gas is supplied to the crank case 29 through the bypass pipe 13 including the check valve 11 and the pressure regulator 12 and the compressed gas inlet 10, thereby The interior of the crankcase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com