Trigger switch

A technology for triggering switches and disconnecting positions, applied in the direction of electric switches, electronic switches, emergency contact forms, etc., can solve the problem of fine-tuning of motor speed, etc., and achieve the effect of easy fine-tuning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

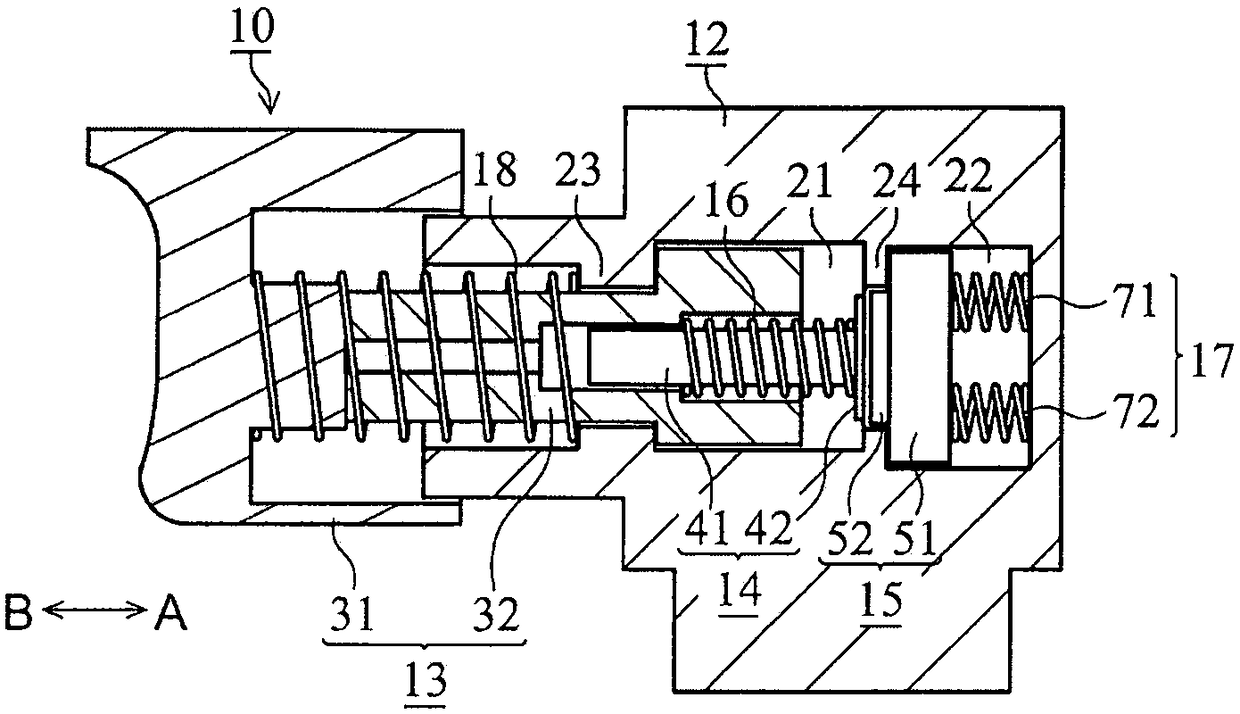

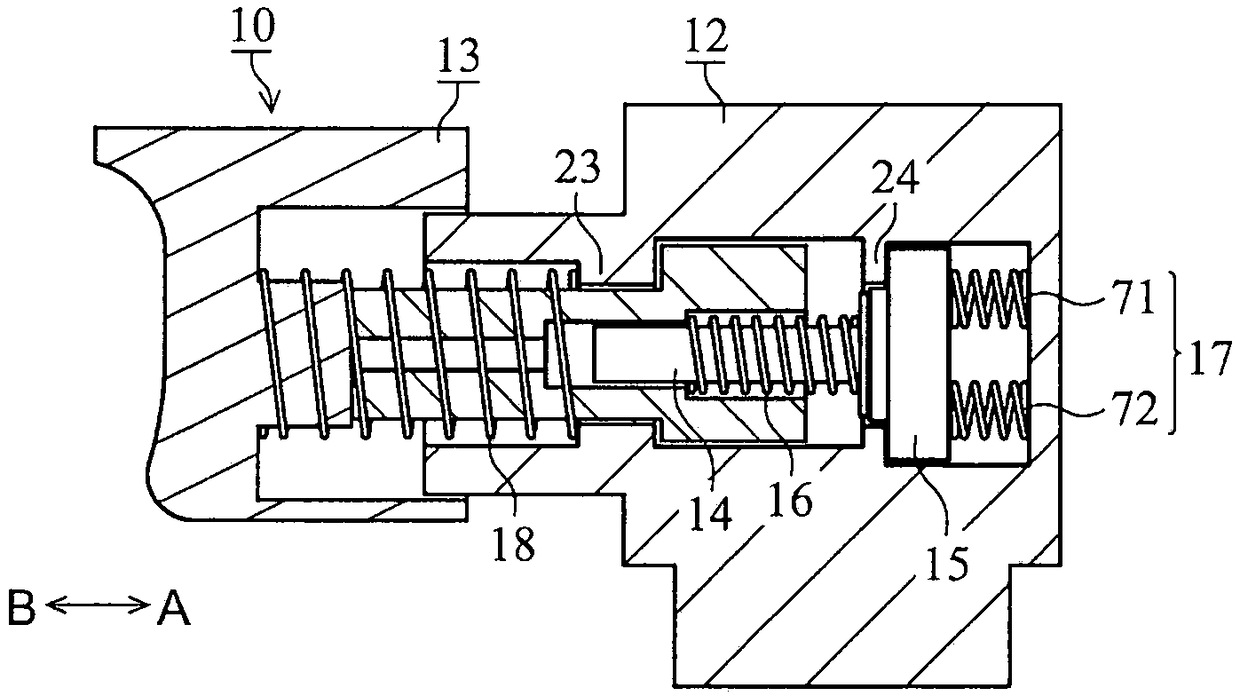

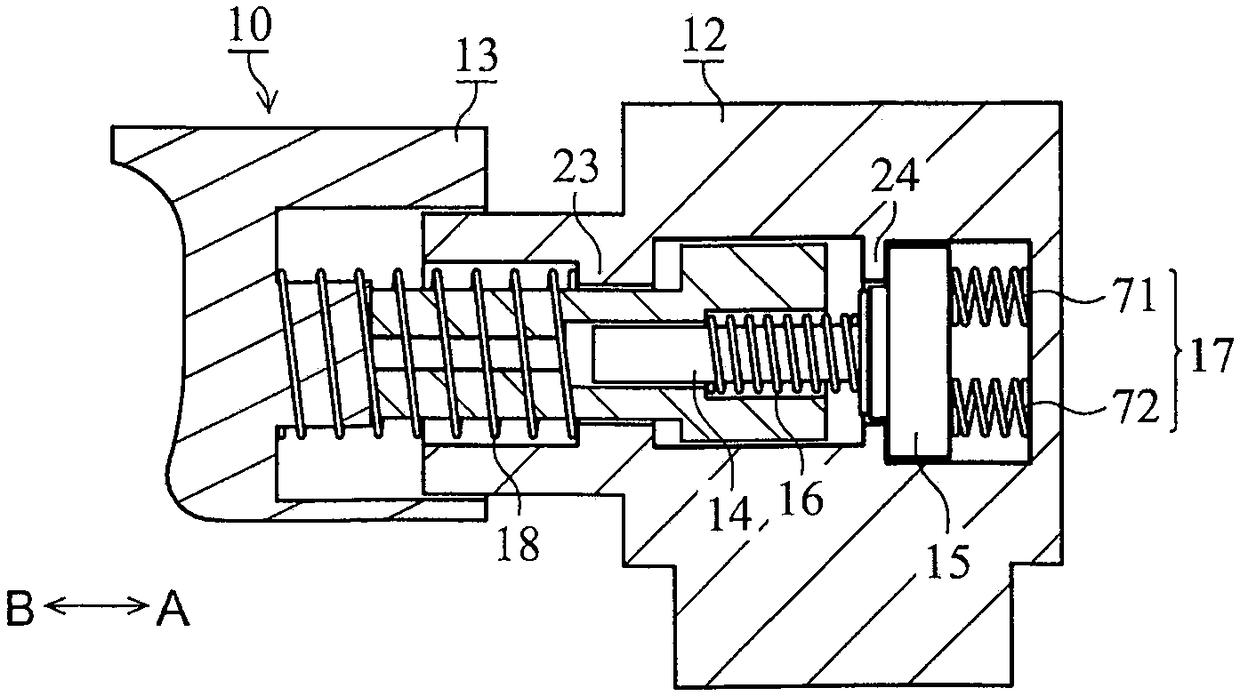

[0037] figure 1 The shown trigger switch 10 is used, for example, in an electric tool including a load such as a motor to adjust the electric power supplied to the load.

[0038] The trigger switch 10 includes a housing 12 . The frame body 12 has two accommodating spaces 21 , 22 and two partition walls 23 , 24 disposed inside. The partition wall 23 is arranged in the direction B of the storage space 21 and separates the storage space 21 from the outside. The partition wall 23 is provided with a through hole that communicates the storage space 21 with the outside. The partition wall 24 is arranged in the A direction of the storage space 21 and in the B direction of the storage space 22 , and partitions the two storage spaces 21 and 22 . The partition wall 24 is provided with a through hole that communicates the two storage spaces 21 and 22 .

[0039] The trigger switch 10 includes an operation unit 13 . The operation part 13 can be positioned relative to the frame body 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com