Straight moving type three-way electromagnetic valve

A three-way solenoid valve, direct-acting technology, applied in the field of solenoid valves, can solve problems such as excessive power consumption, increased power consumption, and reduced valve life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

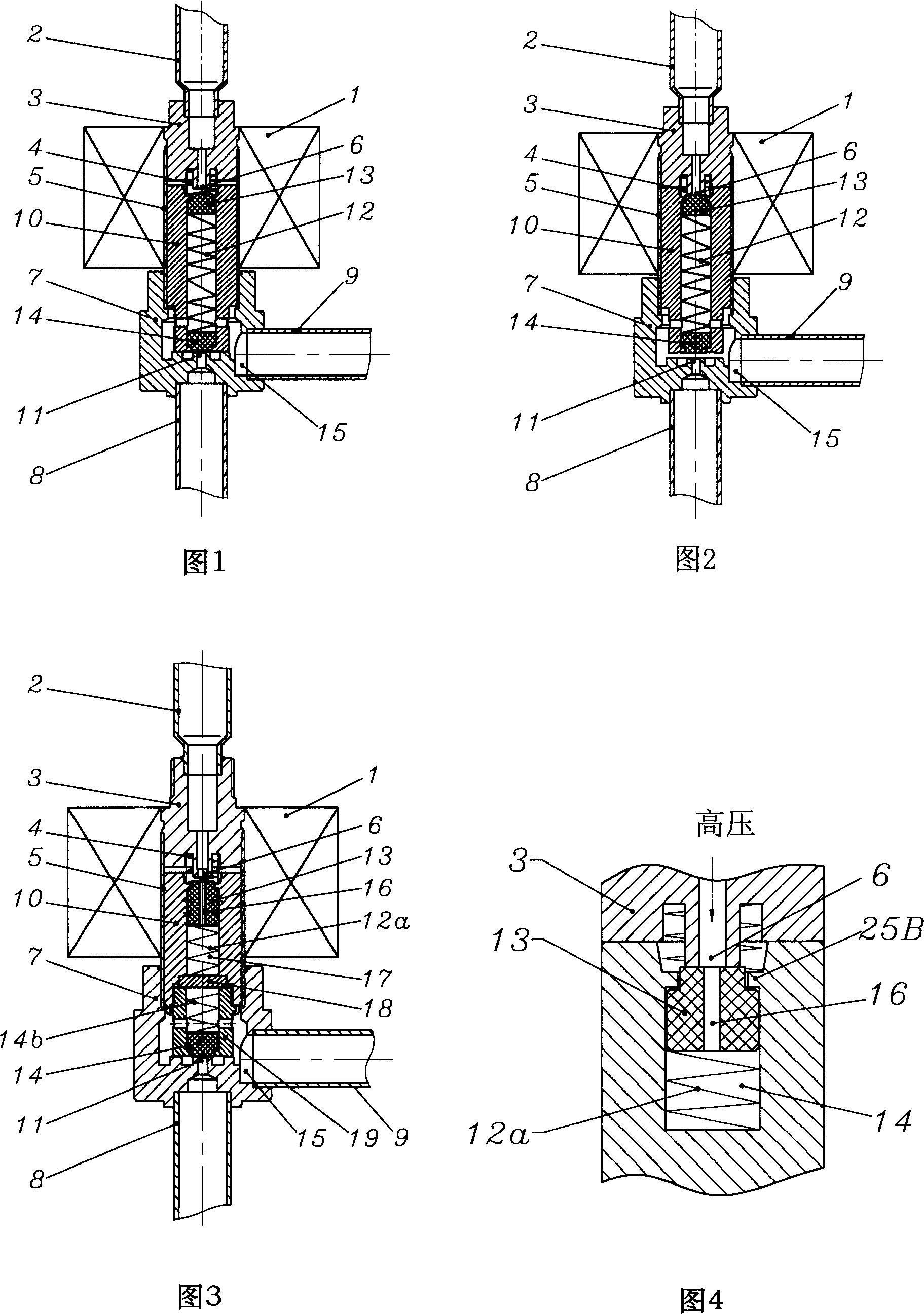

[0029] The new direct-acting three-way solenoid valve shown in Figure 3 includes a head 3 and a valve seat 7 connected to the upper and lower ends of the casing 5, respectively, and the core iron 10 in the casing 5 and the head 3 are reset. Spring 4, A valve port 6 is opened on the head 3 and connected to the A connecting pipe 2, and the B valve port 11 and outlet 15 are opened on the valve seat 7 and connected to the B connecting pipe 8 and the C connecting pipe 9 respectively; in order to facilitate the assembly of A Sealing plug 13, B sealing plug 14 and A spring 12a and B spring 12b supporting them, core iron includes body 10 and end sleeve 19 assembled on the lower end of body 10, A sealing plug 13 and B sealing plug 14 are respectively connected with A valve port 6 corresponds to the B valve port 11; A channel 16 is opened on the A sealing plug 13 to communicate with the closed cavity 17 at the rear end of the A sealing plug 13. The key of this structure is to construct ...

Embodiment 2

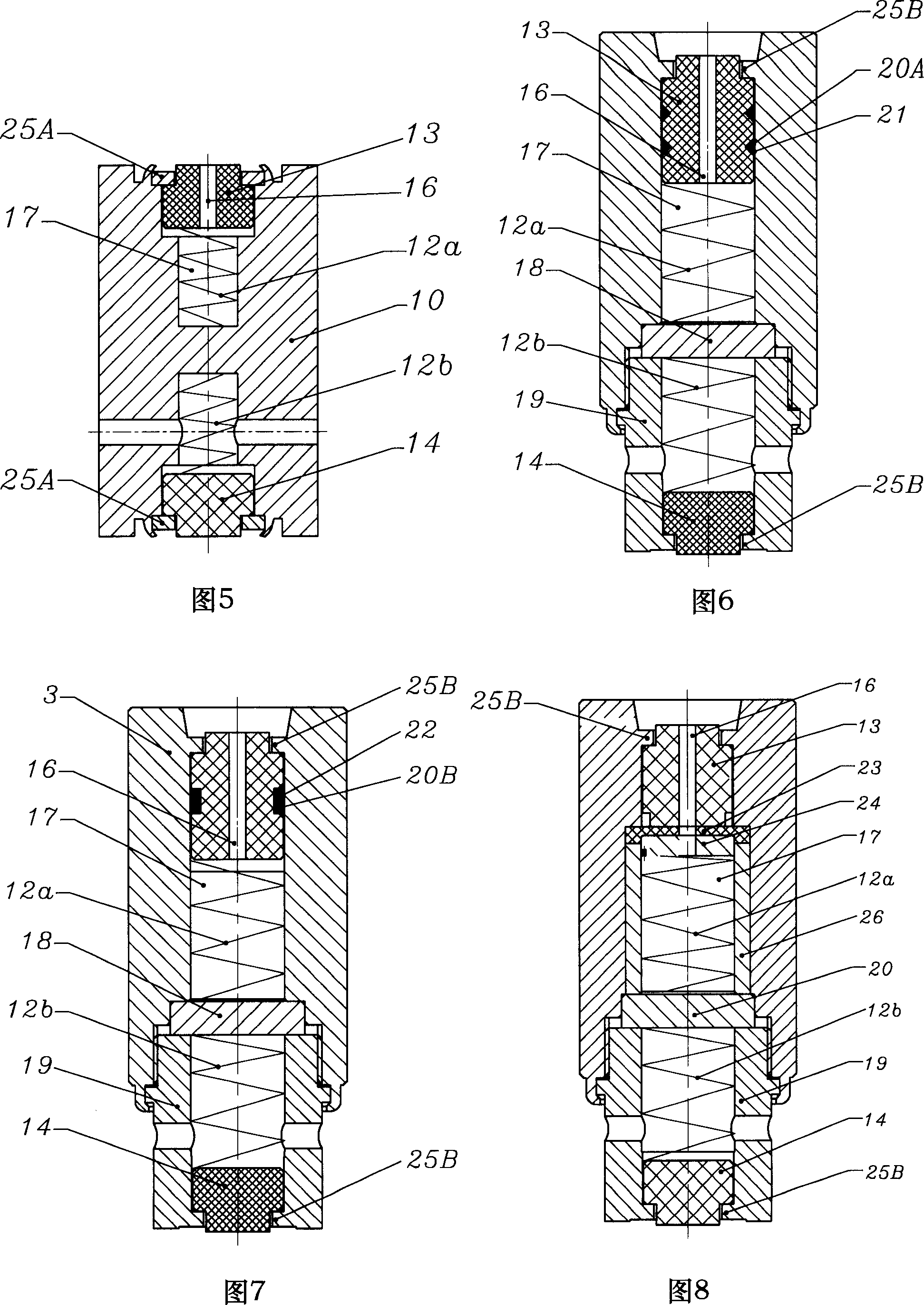

[0031] The difference between the direct-acting three-way solenoid valve shown in Figure 5 and Embodiment 1 is that the core iron 10 has only a part, and there are two blind holes on the core iron 10, and the A spring 12a and the B spring are respectively placed inside. 12b, the outer ends of the two springs respectively support the A sealing plug 13 and the B sealing plug 14, and the sealing plugs are held by the gasket 20 riveted on the end of the core iron. Its working principle is the same as above, and will not be repeated here.

Embodiment 3

[0033] The difference between the direct-acting three-way solenoid valve shown in Figure 6 and Embodiment 1 is that a groove 20A is set on the outer circle of the A sealing plug 13, and the groove is coated with grease, which can reduce the pressure in the inner cavity of the core iron from The periphery of A sealing plug 13 leaks out, so just basically constructed a closed space 17 except the air inlet channel. Its working principle is the same as above, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com