Double-chamber ampoule

A container and flexible technology, applied in the field of double-chamber ampoules, can solve the problems of high manufacturing cost, too large, unusable container solutions, etc., and achieve the effect of rapid absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

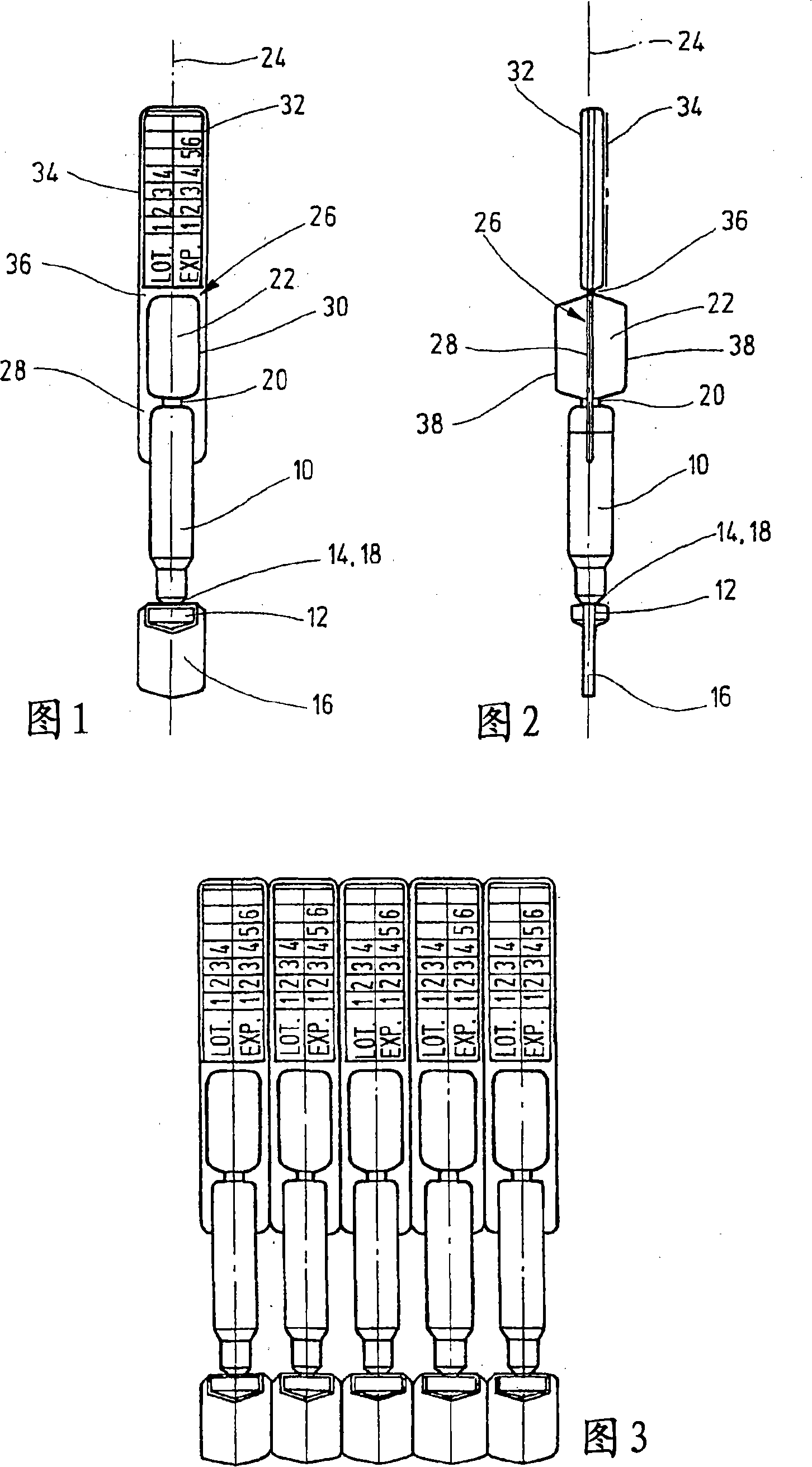

[0016] The container shown in the accompanying drawings consists of a transparent, elastic and flexible plastic, which can be manufactured, filled and non-woven by blow molding machines alone (see Figures 1 and 2) or together with other containers (see Figure 3). bacteria seal. The container has a tubular ingredient chamber 10, the lower end of which is seen in the figure closed by a twist closure (twist closure) 12, which has a constricted break slit 14 and a handle 16 for unscrewing the twist closure 12, to release the discharge opening 18 located at the lower end of the batching chamber 10. There is a conveying medium in the dosing chamber 10, for example a paste-like viscous medium such as eye ointment; the conveying medium preferably also includes a low-viscosity medium or even an aerosol, which can be discharged from the dosing chamber 10 during the spraying process Port 18 exits the container. The tubular structure of the ingredient chamber 10 facilitates insertion in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com