Hydraulically actuated impact apparatus

A drive and impact technology, used in mechanically driven excavators/dredgers, construction, earth movers/shovels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

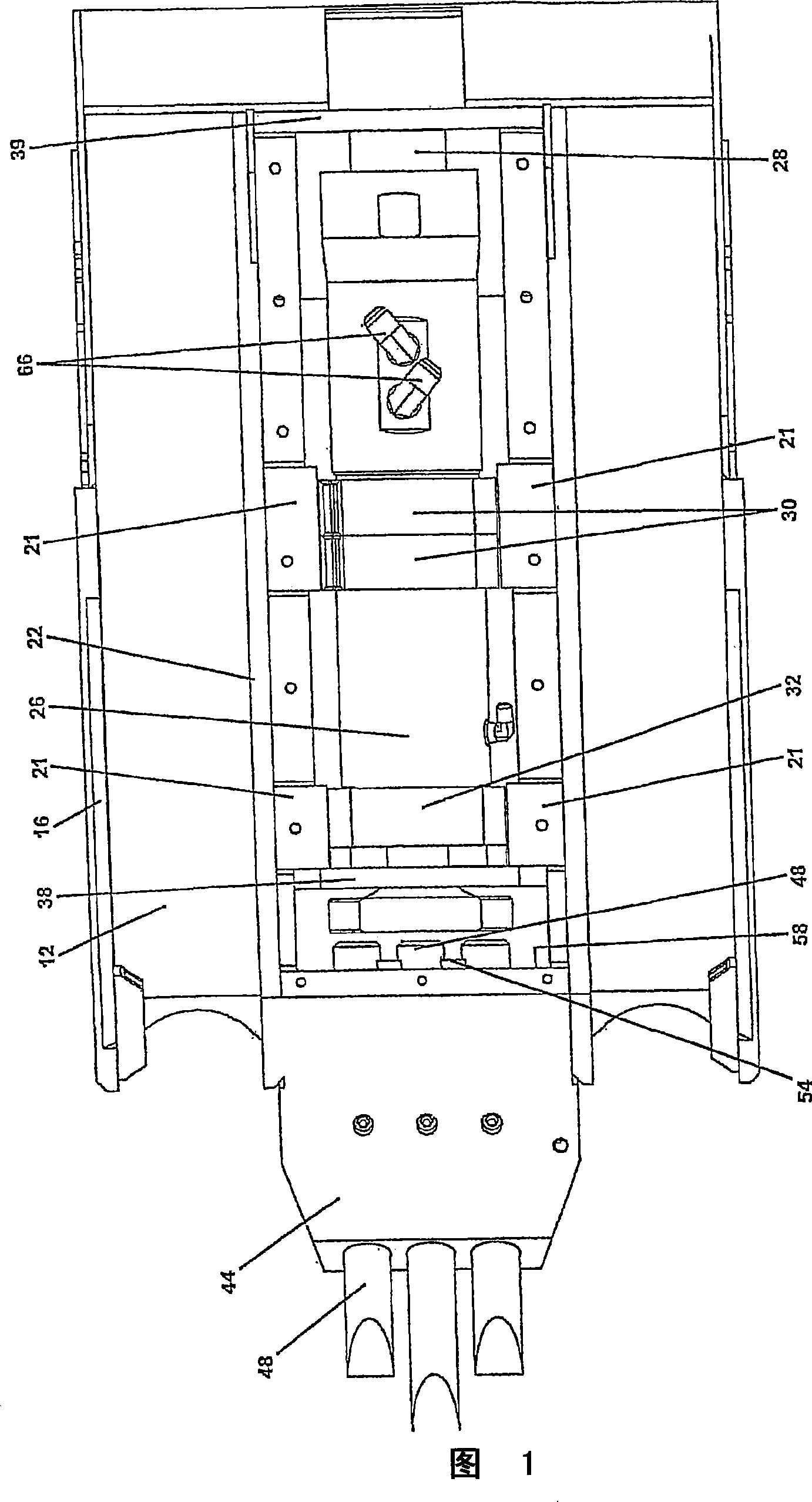

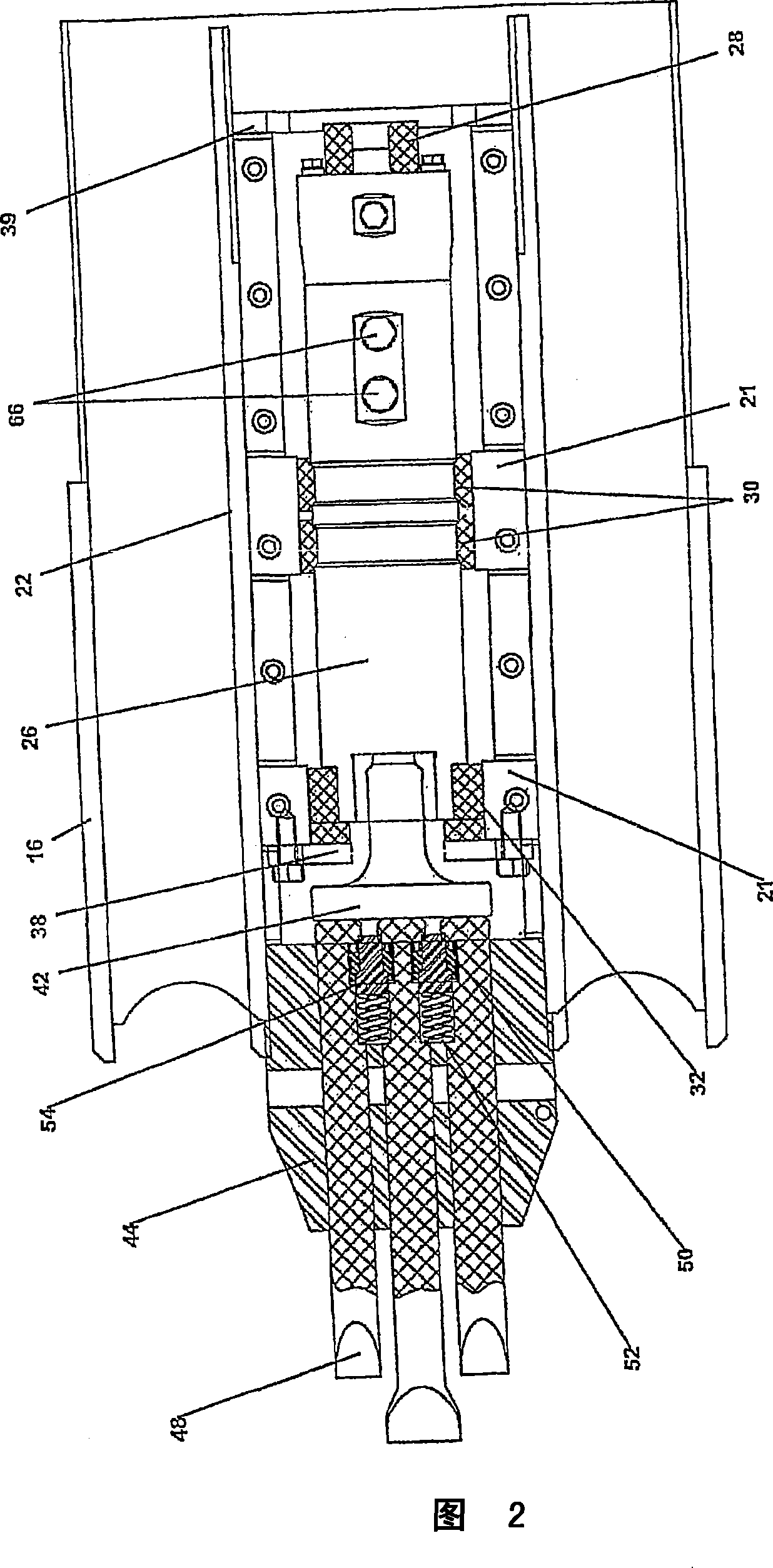

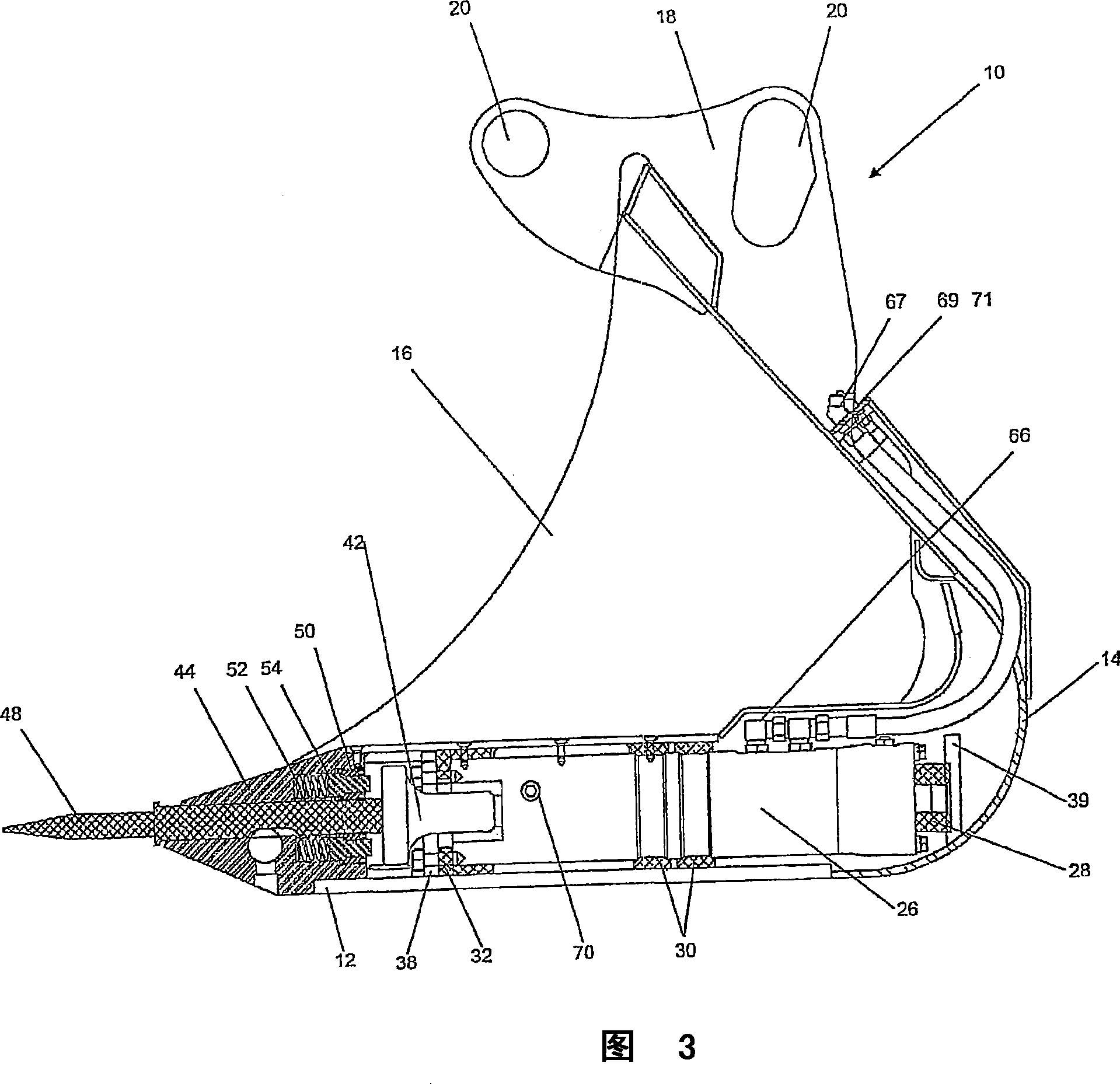

[0043] As mentioned in the Summary of the Invention, the present invention relates to an impact driver assembly. While the impact driver assembly may be used alone, in a preferred embodiment, the impact driver assembly 26 is preferably incorporated into a digging bucket.

[0044] Referring in more detail to the drawings and to the reference numerals therein, a preferred embodiment of the present invention is shown in FIGS. Dig in the bucket. In this regard, the bucket 10 is similar to US Patent No. 6,574,891.

[0045] The bucket 10 has a base 12, a rear wall 14, and side walls 16 with mounting brackets 18 having holes 20 in the upper surface for securing purposes.

[0046] Based on its purpose and its width, each bucket 10 is fitted with one or more impact drive assemblies 26 (for a multipurpose impact drive, see Figures 13-17). When used in series (more than one impact driver assembly per bucket 10), each impact driver assembly 26 is mounted side by side, separated by an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com