A method of cutting off laminate layers, eg a glass-fibre or carbon-fibre laminate layer in the blade of a wind turbine

A technology for wind turbines, cutting methods, applied in the field of laminated layers, capable of solving problems such as delamination problems not given

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

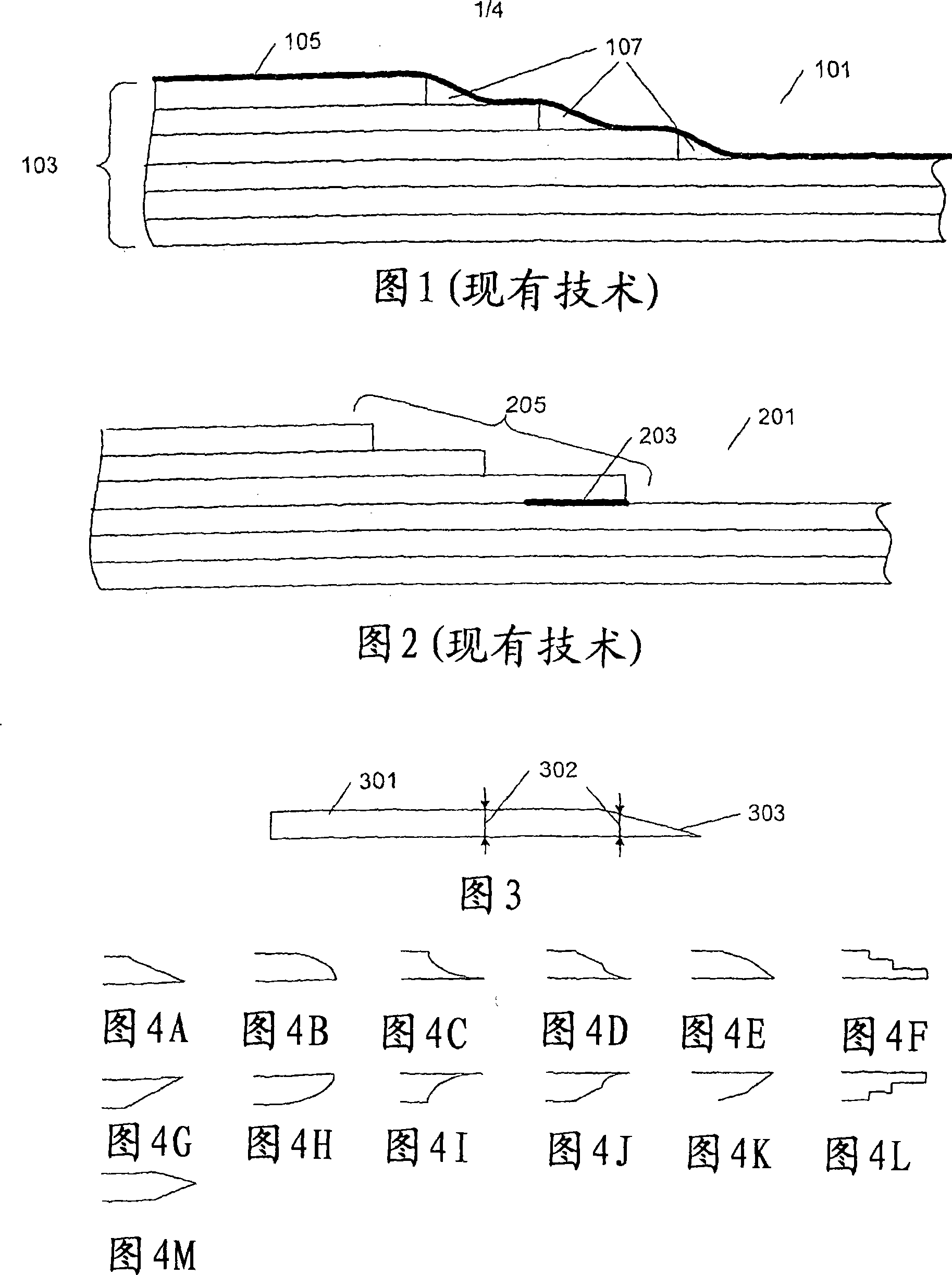

[0026] FIG. 1 is a cross-sectional view of a portion of a known laminated object 101 comprising a plurality of combined laminated layers 103 , wherein the laminated object is made thinner by varying the number of laminated layers 103 . In FIG. 1 , the laminated object 101 initially comprises six laminated layers 103 , and the number of laminated layers 103 is gradually reduced to three laminated layers 103 , whereby the thickness of the laminated object 101 is halved. This decrement occurs gradually to avoid clearly showing notches that would lead to a weakening of the laminated object's strength, but can also occur in areas where the load on the laminated object is not too high. The weight of the laminated layers is minimized. Figure 1 also shows the upper layer 105 and the air pockets 107 and resin-rich regions formed between the upper layer 105 and the lower layer due to taper that can lead to wrinkling in the laminated surface. To avoid these air pockets, where fiberglass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com