An atomizing spray cooling method for producing cooled meat

A technology of atomization spraying and cooling method, which is applied in chemical instruments and methods, preservation of meat/fish through freezing/cooling, preservation of meat/fish with chemicals, etc. It can solve the problems of different spraying durations and carcass quality effects, etc. question

Active Publication Date: 2010-08-11

JIANGSU SUSHI MEAT

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

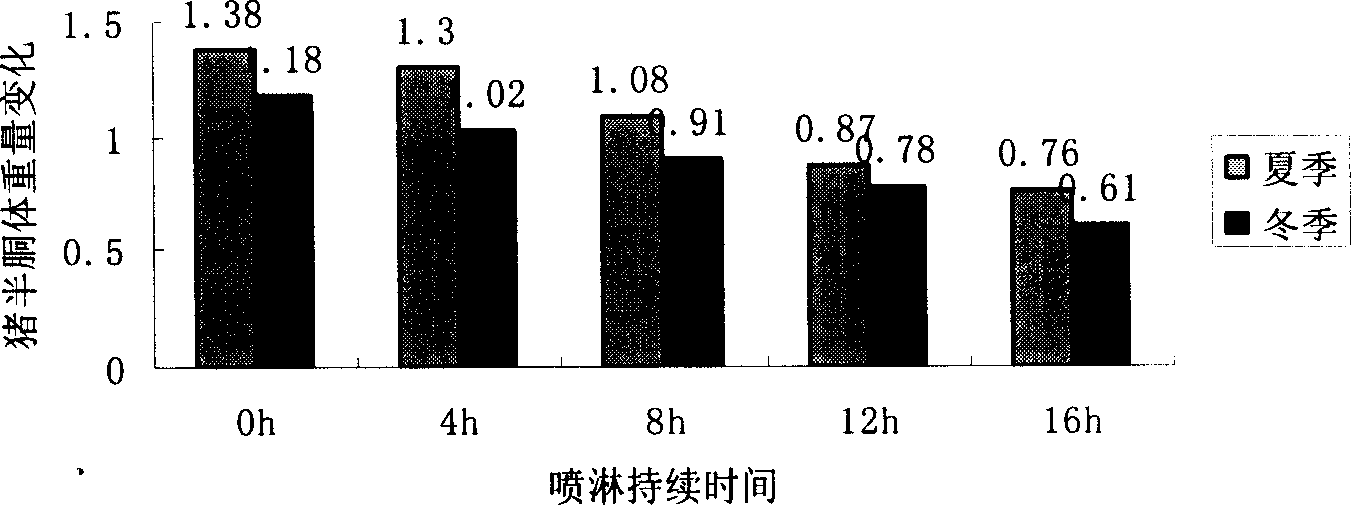

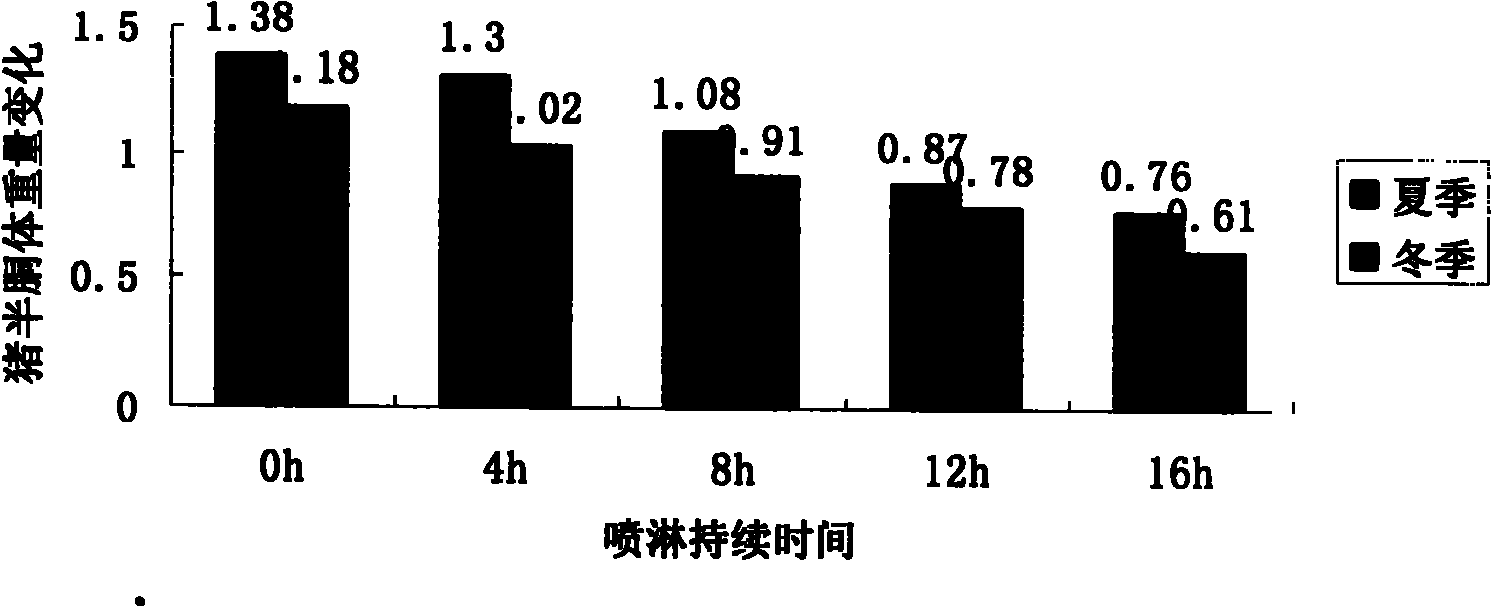

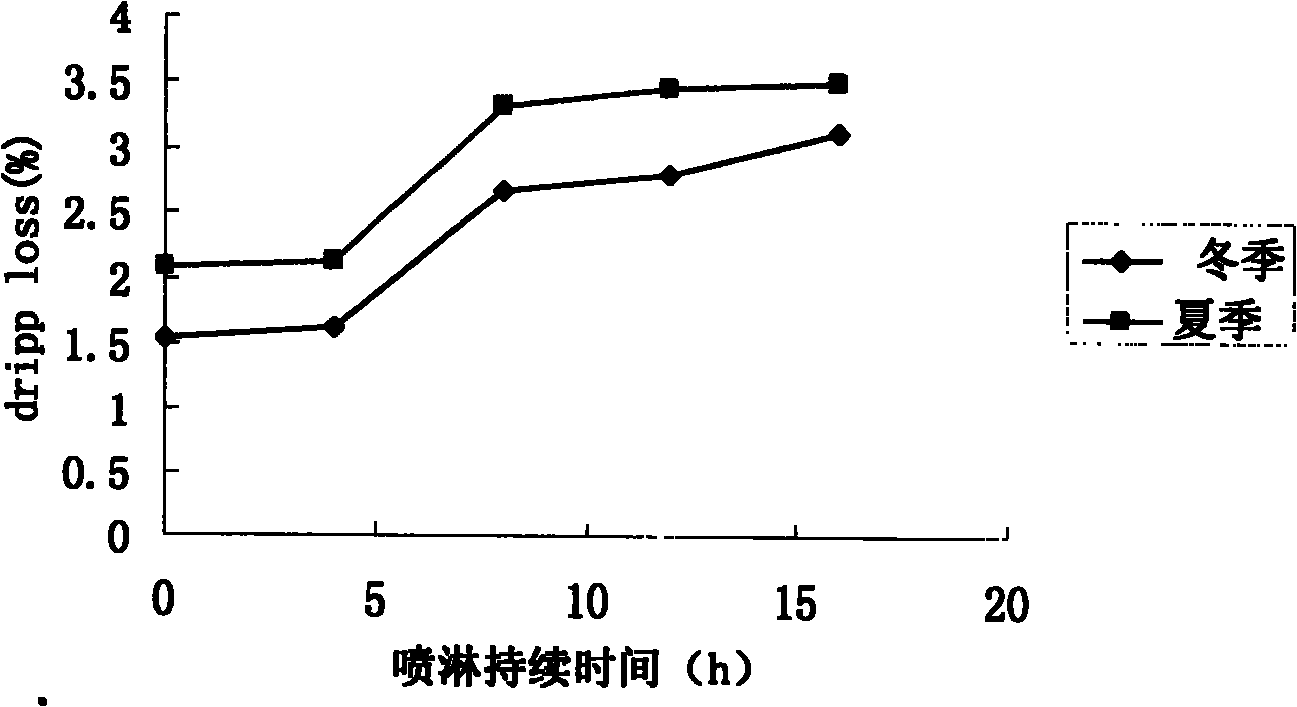

Although it can reduce dry consumption, the difference in the duration of spraying may have an impact on carcass quality, but there is no consistent conclusion on this

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the field of meat processing, specifically to a method for producing cooling meat with atomization showering cooling method. The method comprises: interval -showering (showering for 40-60s every 30min-50min) the half naked body with water at 0-5DEG C for 8-12h. The atomization showering cooling method can reduce energy consumption, keep good quality of the naked body, andhas broad application perspective.

Description

technical field The invention relates to the field of meat processing, in particular to an atomization spray cooling method for cooling meat production. Background technique "Mist spray cooling" began in the late 1880s to find a technology that could not only accelerate the cooling of pig carcasses but also reduce the loss of water during cooling. Smith and Carpenter (1973) proposed that the water loss during cooling includes evaporation loss and drip loss. In order to reduce the water loss of carcasses, the cooling room should maintain lower temperature, lower air circulation and higher relative humidity. Atomized spraying is a process in which cold water at 0-5°C is converted into fine droplets through spraying equipment and sprayed on the pig half-carcass. Due to the high-speed movement of the cold water relative to the air or gas in the nozzle, or due to the application of mechanical energy and the rotation or vibration of the injection device, the water is atomized in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): A23B4/06A23B4/20C09K15/06

Inventor 周光宏徐幸莲张向前张楠孟利忠葛晨书孟令云

Owner JIANGSU SUSHI MEAT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com