Automatic welting sewing machine

A sewing machine and hemming technology, applied in the direction of sewing machine components, program-controlled sewing machines, sewing equipment, etc., to achieve the effect of easy configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] (The overall configuration of the hemming sewing machine)

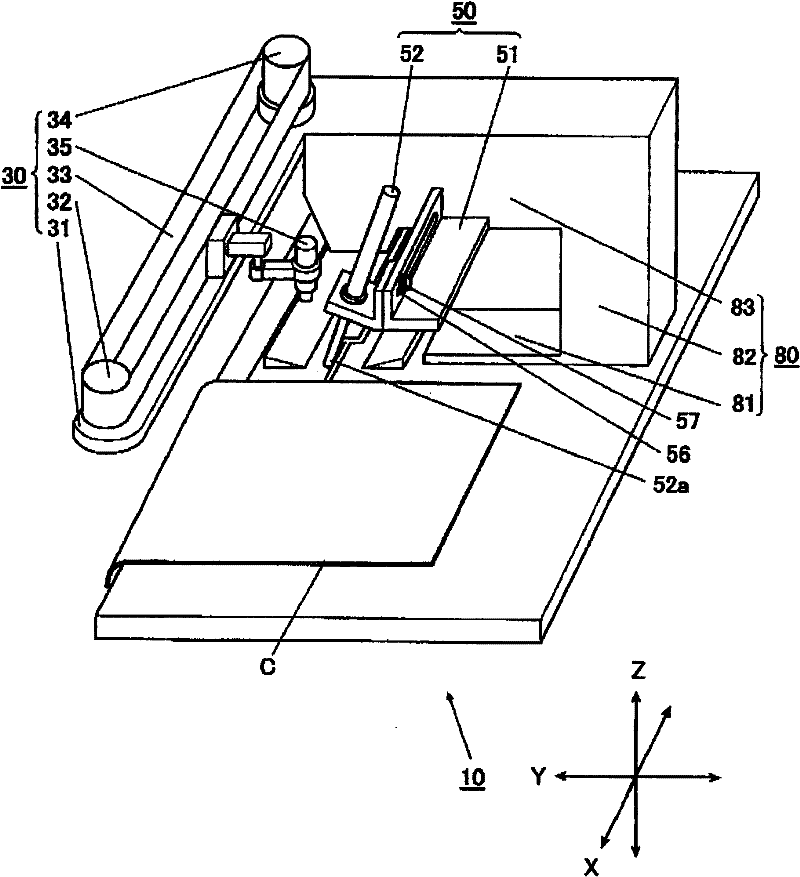

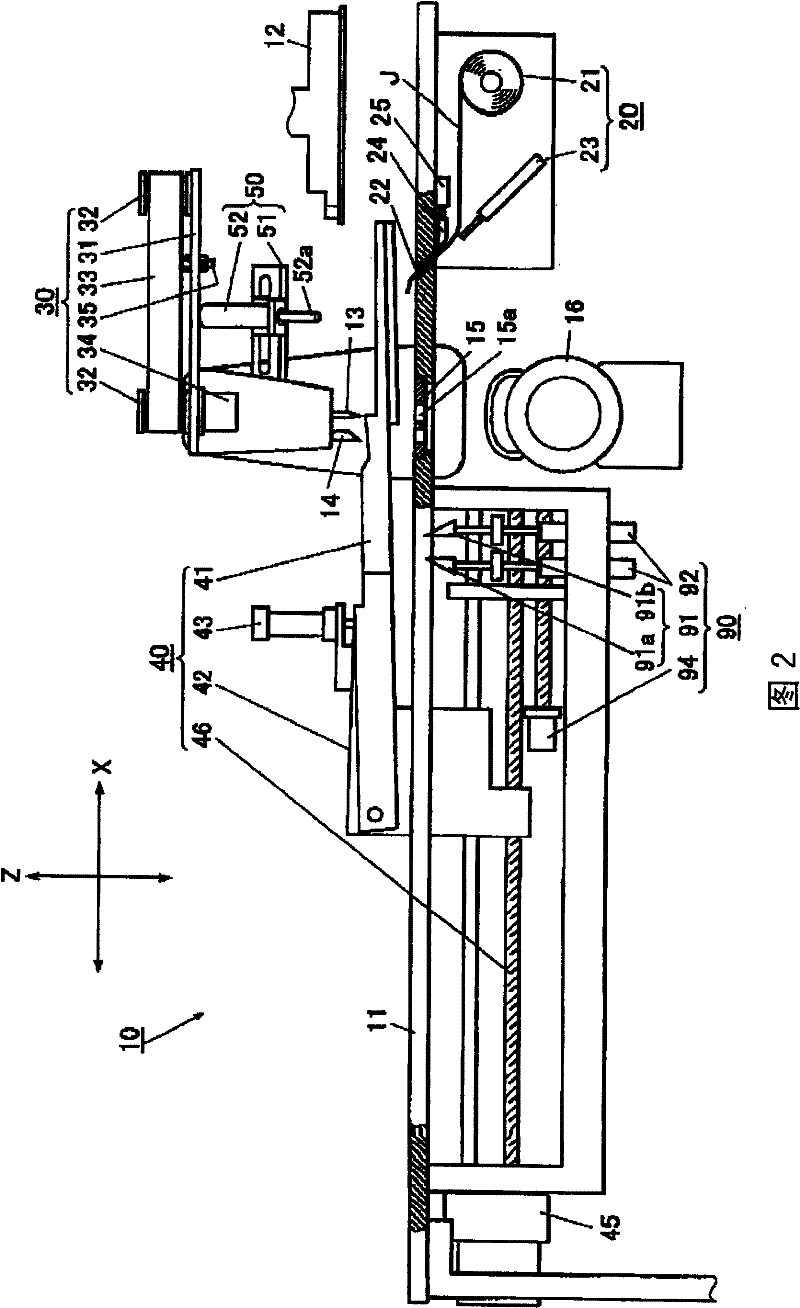

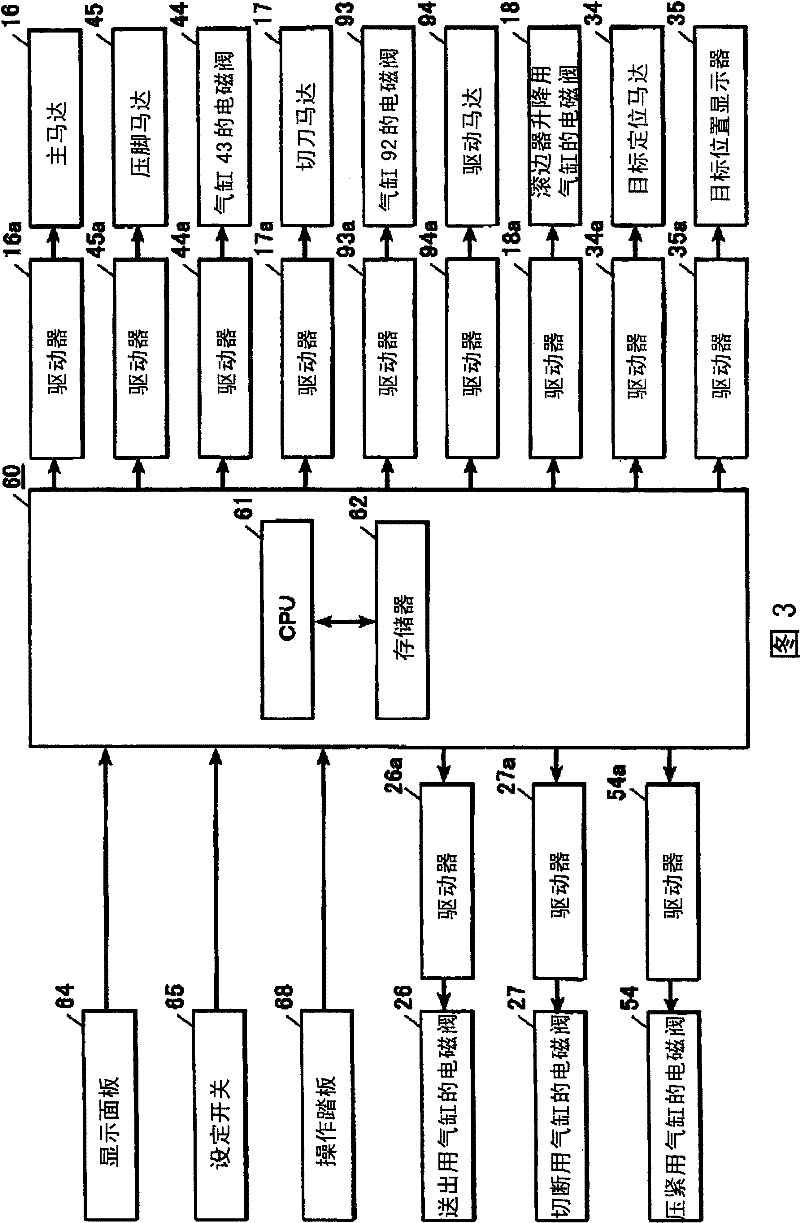

[0094] Below, based on Figure 1 to Figure 12 A piping sewing machine 10 according to an embodiment of the present invention will be described. figure 1 It is a perspective view showing the overall schematic configuration of the hemming sewing machine 10, figure 2 is the front view of the piping sewing machine 10, image 3 It is a block diagram showing a control system of the hemming sewing machine 10 . In addition, in this embodiment, the direction of each part of the sewing machine 10 is determined based on the XYZ axis|shaft shown in each figure. When the sewing machine is installed on a horizontal plane, the Z-axis direction indicates a vertical direction, the X-axis direction indicates a horizontal direction that coincides with the cloth feeding direction, and the Y-axis indicates a horizontal and perpendicular direction to the X-axis direction.

[0095] This hemming sewing machine 10 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com