Centralized type sunshade refrigerating and heating system and operation method thereof

A refrigeration system and centralized technology, applied in hot water central heating systems, air conditioning systems, heating systems, etc., can solve the problem of slow temperature regulation, not meeting the requirements of national household measurement, and ground furniture affecting the effect of heat dissipation and other problems, to achieve the effect of low cost and high heating and cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

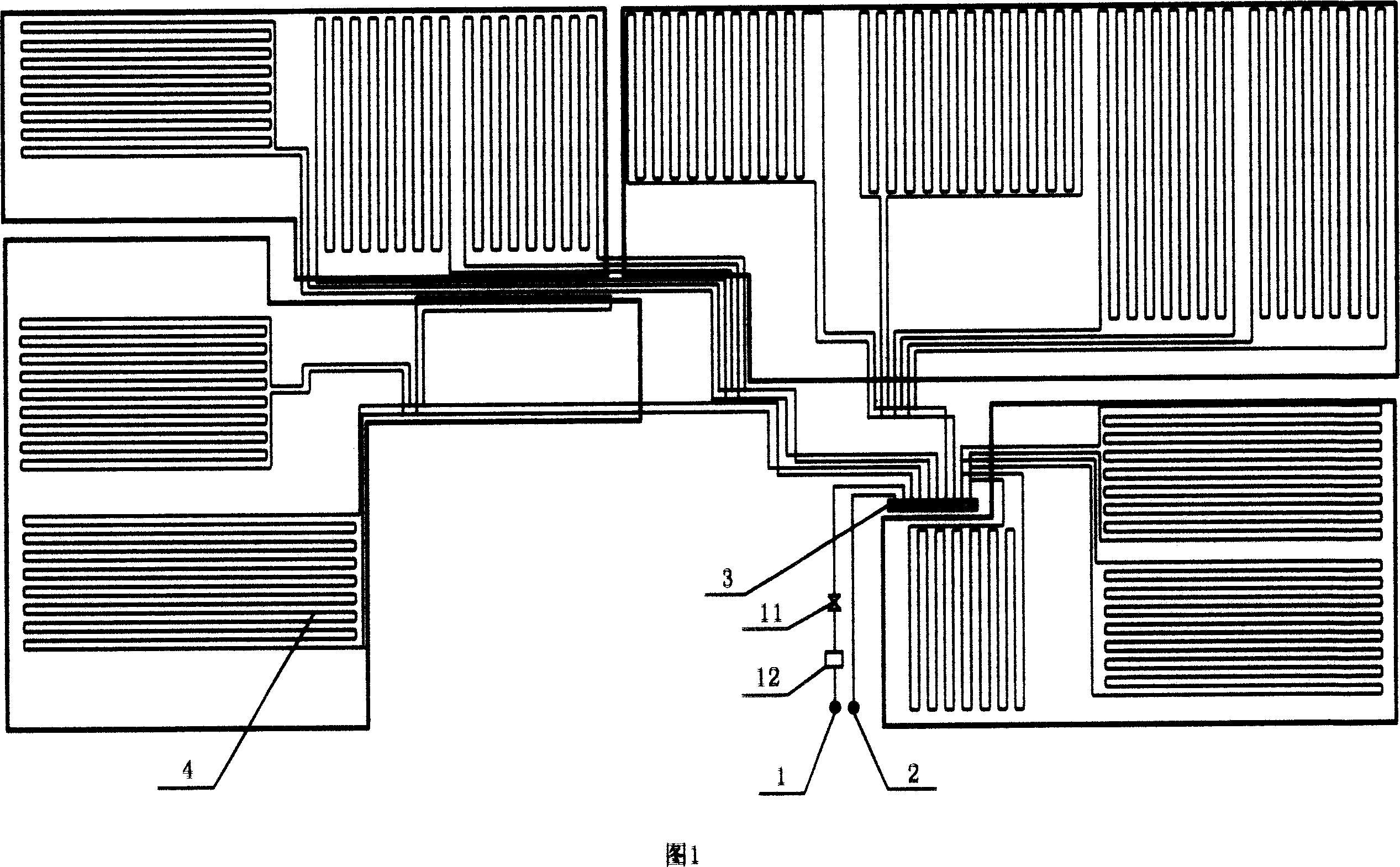

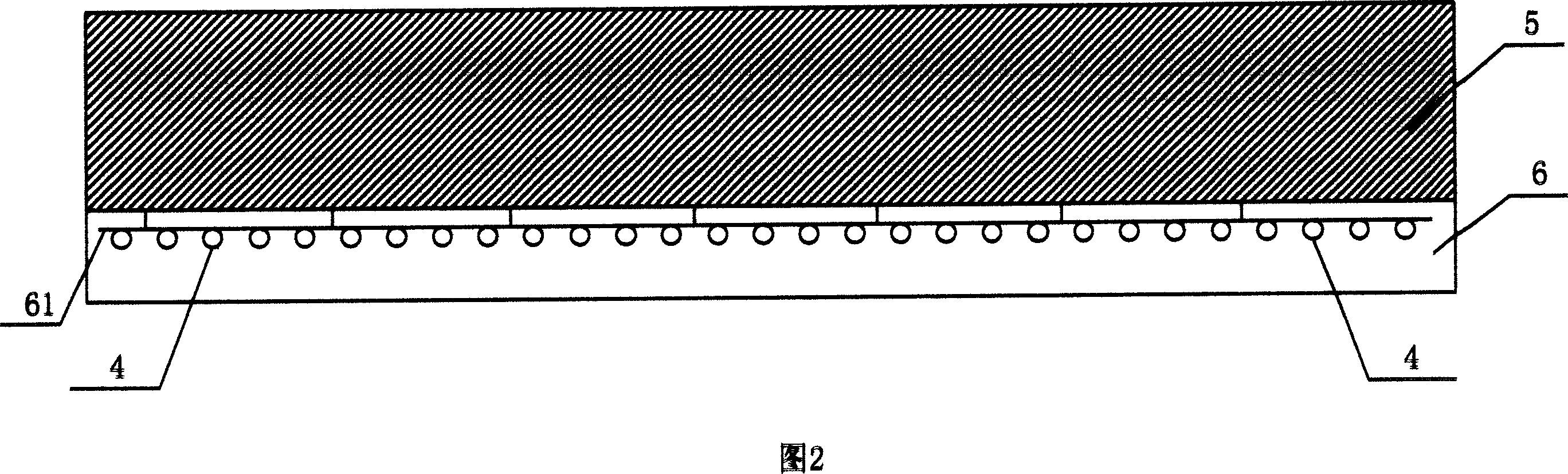

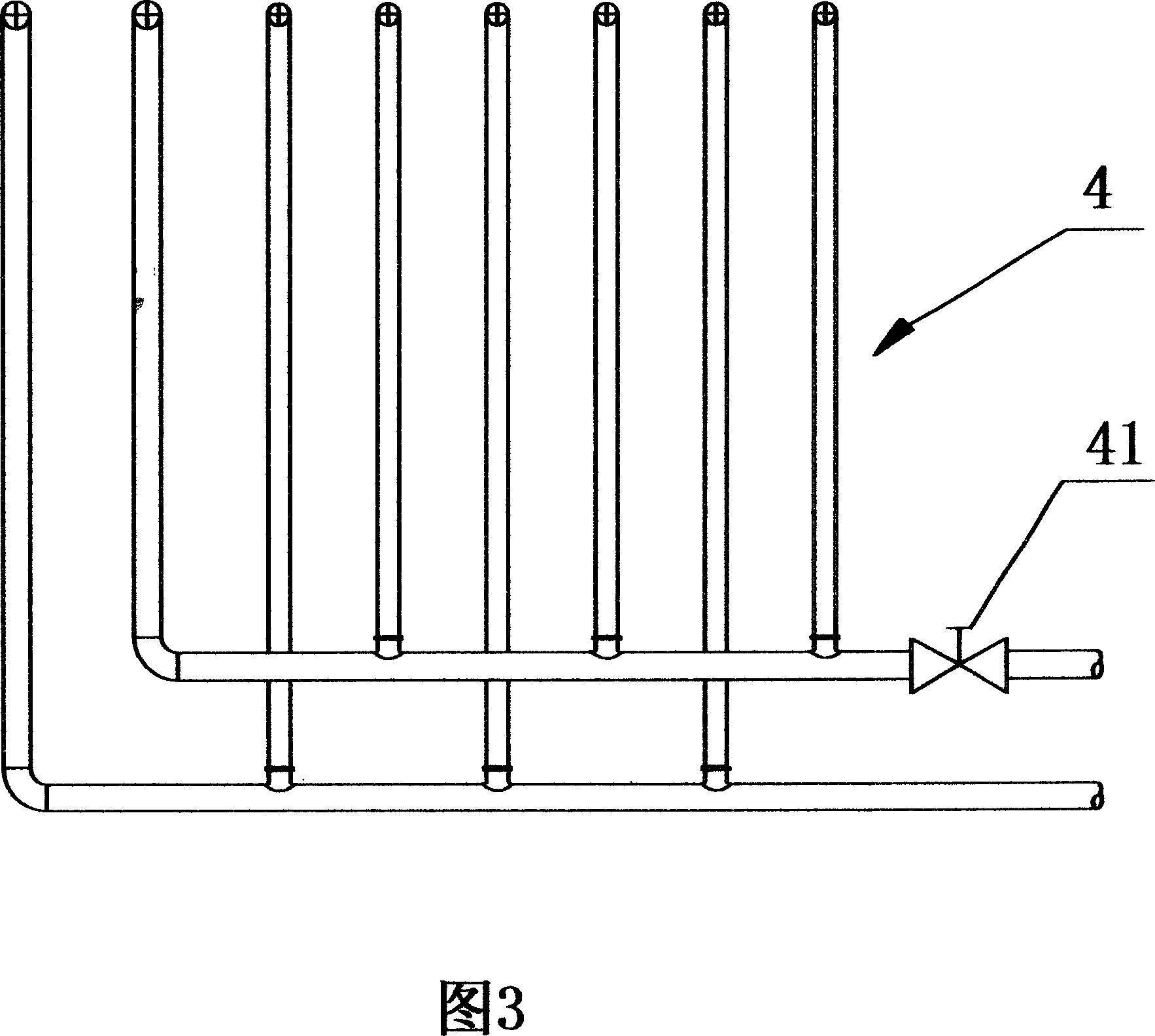

[0017] Referring to Figures 1, 2, and 3, the centralized ceiling heating and cooling system is composed of a centralized water supply pipe 1, a centralized drain pipe 2, a heat medium distribution device 3, and a heating and cooling pipeline 4; the heating and cooling pipeline 4 is located in In the plastering layer 6 below each indoor ceiling 5, in order to fix the heating and cooling pipeline, a steel mesh 61 for fixing the heating and cooling pipeline is also arranged in the plastering layer, and the steel mesh 61 is fixed on the ceiling 5; the centralized water supply pipe 1 It is connected with the heat medium collecting and distributing device 3 , and the heat medium collecting and distributing device 3 is connected with each heating and cooling pipeline 4 , and the centralized drain pipe 2 is also connected with the heat medium collecting and distributing device 3 .

[0018] In order to make the heating and cooling efficiency higher, the heating and cooling pipeline 4 is...

Embodiment 2

[0023] Referring to Figures 1, 2, and 3, the centralized ceiling heating and cooling system is composed of a centralized water supply pipe 1, a centralized drain pipe 2, a heat medium distribution device 3, and a heating and cooling pipeline 4; the heating and cooling pipeline 4 is located in In the plastering layer 6 below each indoor ceiling 5, in order to fix the heating and cooling pipeline, a steel mesh 61 for fixing the heating and cooling pipeline is also arranged in the plastering layer, and the steel mesh 61 is fixed on the ceiling 5; the centralized water supply pipe 1 It is connected with the heat medium collecting and distributing device 3 , and the heat medium collecting and distributing device 3 is connected with each heating and cooling pipeline 4 , and the centralized drain pipe 2 is also connected with the heat medium collecting and distributing device 3 .

[0024] In order to make heating and cooling more efficient, the heating and cooling pipeline 4 is a plas...

Embodiment 3

[0029] Referring to Figures 1, 2, and 3, the centralized ceiling heating and cooling system is composed of a centralized water supply pipe 1, a centralized drain pipe 2, a heat medium distribution device 3, and a heating and cooling pipeline 4; the heating and cooling pipeline 4 is located in In the plastering layer 6 below each indoor ceiling 5, in order to fix the heating and cooling pipeline, a steel mesh 61 for fixing the heating and cooling pipeline is also arranged in the plastering layer, and the steel mesh 61 is fixed on the ceiling 5; the centralized water supply pipe 1 It is connected with the heat medium collecting and distributing device 3 , and the heat medium collecting and distributing device 3 is connected with each heating and cooling pipeline 4 , and the centralized drain pipe 2 is also connected with the heat medium collecting and distributing device 3 .

[0030] In order to make the heating and cooling efficiency higher, the heating and cooling pipeline 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com