Zoom lens

A zoom lens and lens technology, which is applied in the field of zoom lenses, can solve the problems of increasing the diopter of the lens group and increasing the fluctuation of aberrations, and achieves the effects of increasing miniaturization and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] First of all, it should be pointed out that although in the embodiments described below, the zoom lens of the present invention is used as an optical projection lens of a projection device, the zoom lens of the present invention can also be used as an optical imaging lens in an imaging device .

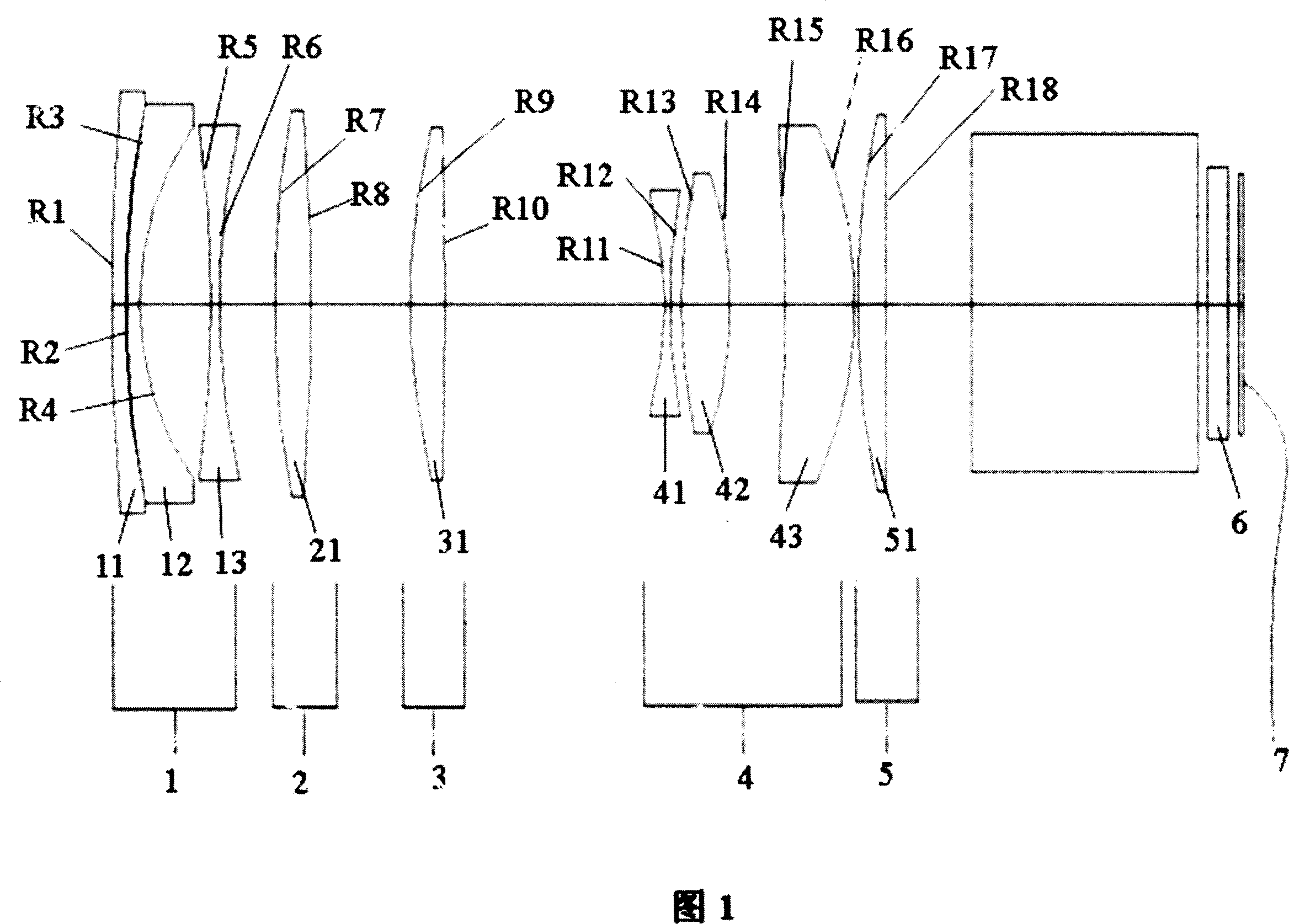

[0043]Fig. 1 is an optical structure diagram of the zoom lens of the present invention, showing the optical structure of the zoom lens positioned at the front end of the optical device at the wide-angle end state. The zoom lens of the present invention is composed of five lens groups, that is, from the object side (enlargement side, the enlarged side of the projection system) to the image plane side (reduction side, the reduced side of the projection system) sequentially includes the first lens Group 1, second lens group 2, third lens group 3, fourth lens group 4 and fifth lens group 5, wherein the first lens group 1 has a negative diopter, the second lens group 2 has a positiv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap