Photomask substrate container unit, photomask substrate transportation and exposal method

A photomask and substrate technology, which is applied in the field of photomask substrate container units, can solve the problems of vertical type photomask boxes being easy to fall down, difficult transportation of photomask boxes, accidental fall of photomask boxes, etc. , to achieve the effect of preventing vision obstruction, overcoming restrictions, and preventing falling down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

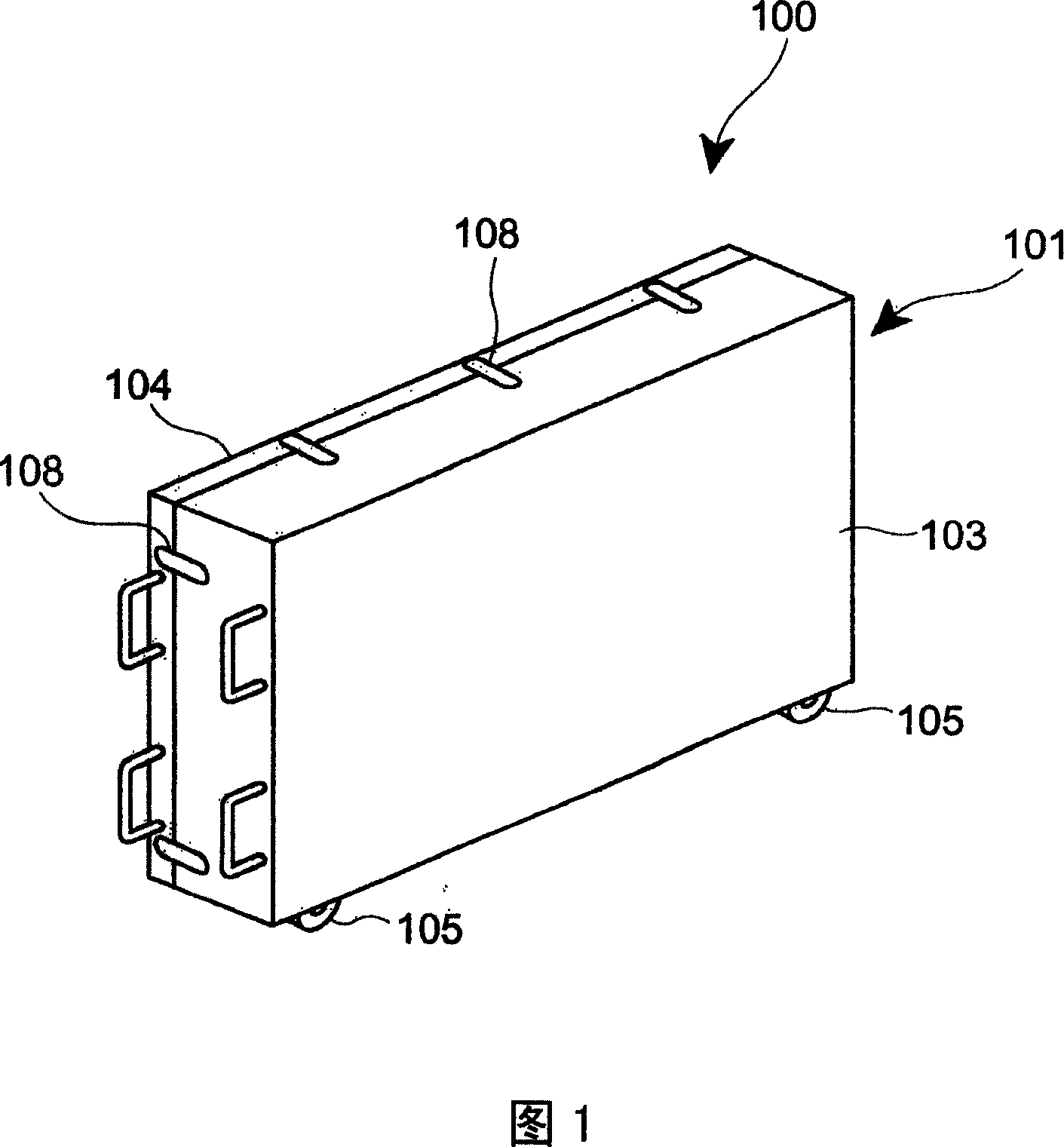

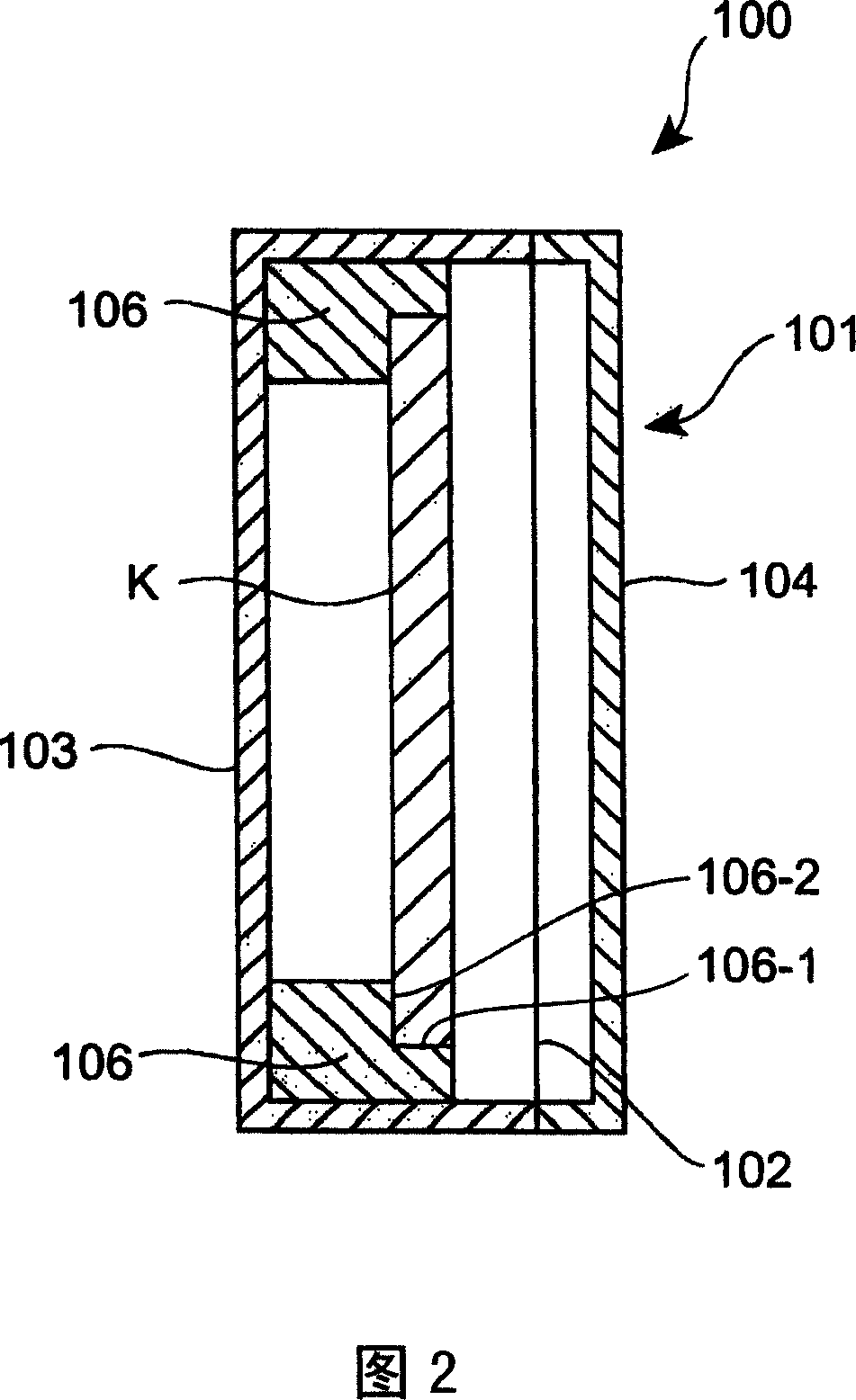

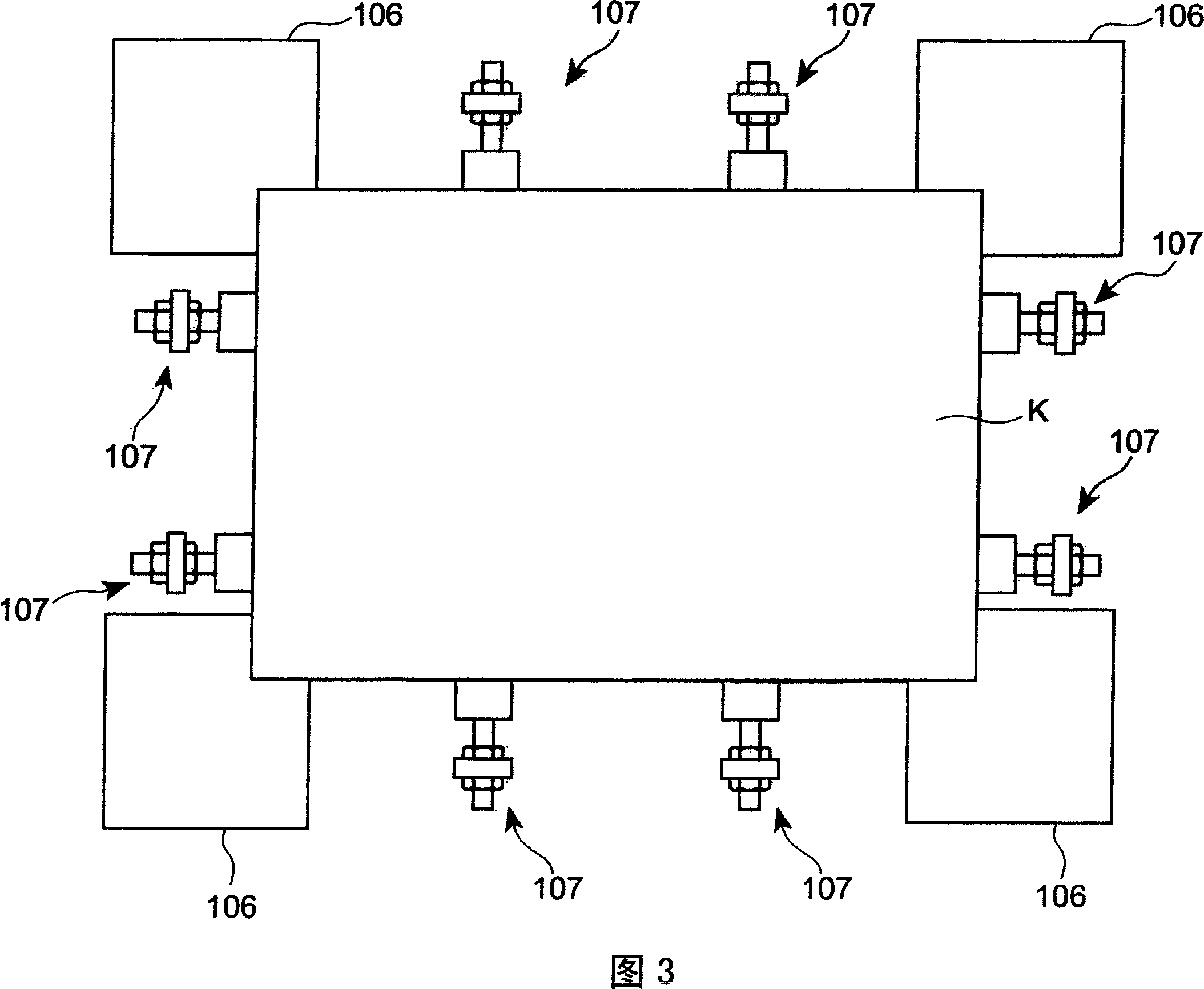

[0043] 4 is a schematic perspective view showing a photomask substrate container unit according to one embodiment of the present invention, FIG. 5 is a cross-sectional view viewed from the side of the photomask substrate container unit shown in FIG. 4 , and FIG. 6 is an internal front view of the photomask substrate container unit shown in FIG. 4 . 7 is an explanatory graph for calculating the weight of the photomask substrate container unit shown in FIG. 4, and FIG. 8 is a graph showing the weight of the photomask substrate container unit shown in FIG.

[0044] As shown in these figures, the photomask substrate container unit 1 is a rectangular parallelepiped box for transporting a photomask substrate K, and includes a housing 10 for accommodating a photomask therein. a mold substrate K; and a holding member (described later) for holding the photomask substrate K within the housing 10 .

[0045] The photomask substrate container unit 1 is advantageous when the photomask subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com