High-definition plasma display panel with enlarged discharge space

A high-definition, display panel technology, used in static indicators, instruments, solid cathode components, etc., can solve the problems of reducing discharge efficiency and power efficiency, increasing discharge voltage, and narrowing discharge space, so as to improve discharge efficiency and Efficiency of power supply, increase of discharge space, effect of reducing the loss of charged particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

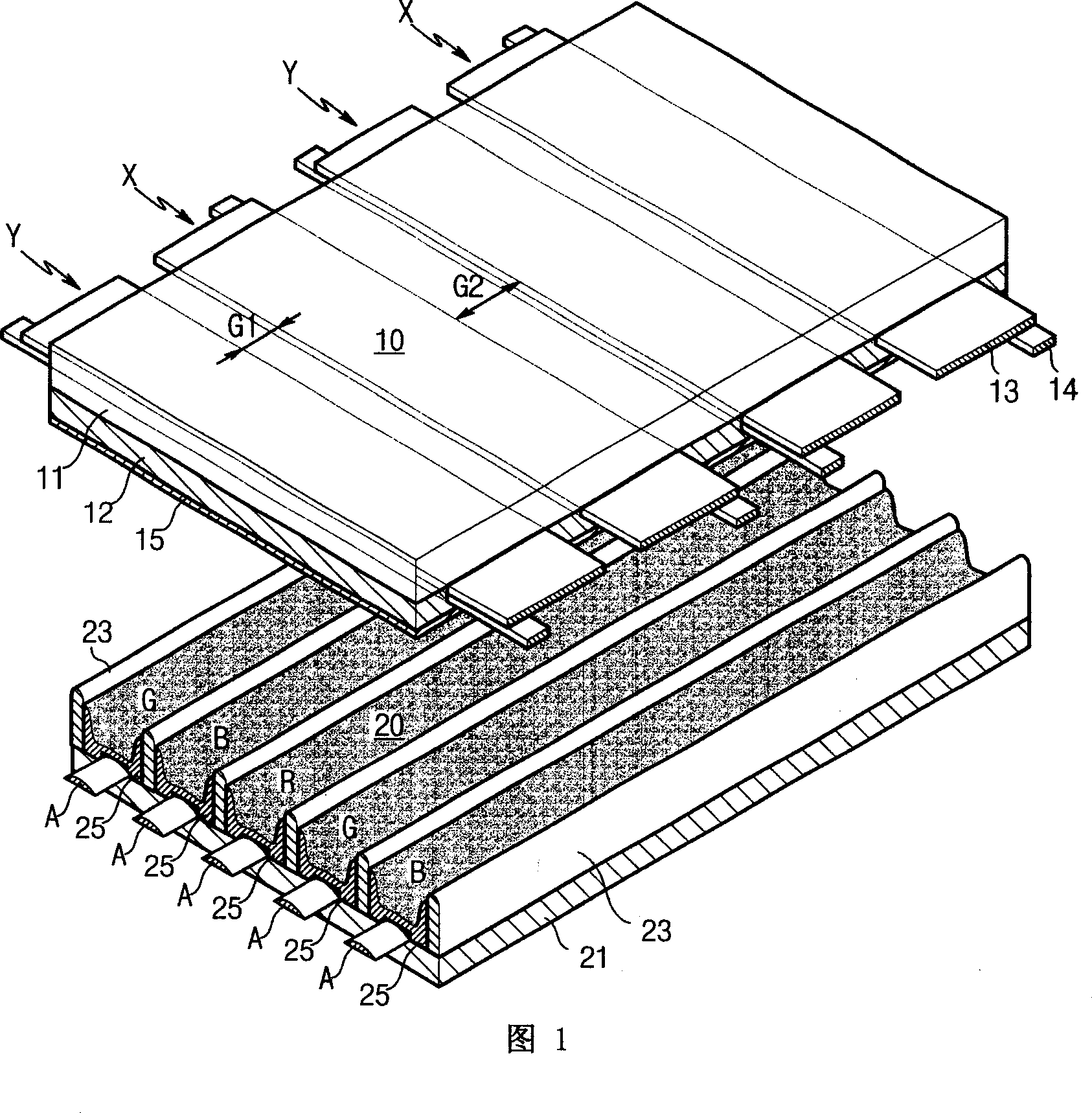

[0046] Hereinafter, preferred embodiments are given, and detailed descriptions are given in conjunction with the accompanying drawings.

[0047] Fig. 6 is a schematic diagram of the PDP structure in the first embodiment of the present invention. The structure of the PDP in this embodiment improves the distribution of a plurality of sustain electrodes (X) and scan electrodes (Y) arranged on the upper plate 210. Unlike the prior art in FIG. 5 , a pair of sustain electrodes ( X) and a pair of scanning electrodes (Y). That is, adjacent upper and lower discharge cells (cells) are symmetrical to each other, and the sustain electrode (X) of the upper discharge cell (cell) and the lower discharge cell (cell) are not scan electrodes (Y) but sustain electrodes (X). ) adjacent.

[0048] The structure of this embodiment is simply repeated alternately with the sustain electrodes (X) and scan electrodes (Y) in the upper plate 110. As shown in FIG. 5, the sustain electrodes (X) and the sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com