Laser cutting method

一种激光切割、轮廓的技术,应用在激光焊接设备、涡轮机、制造工具等方向,能够解决溅回、不能避免熔融的金属、不理想等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

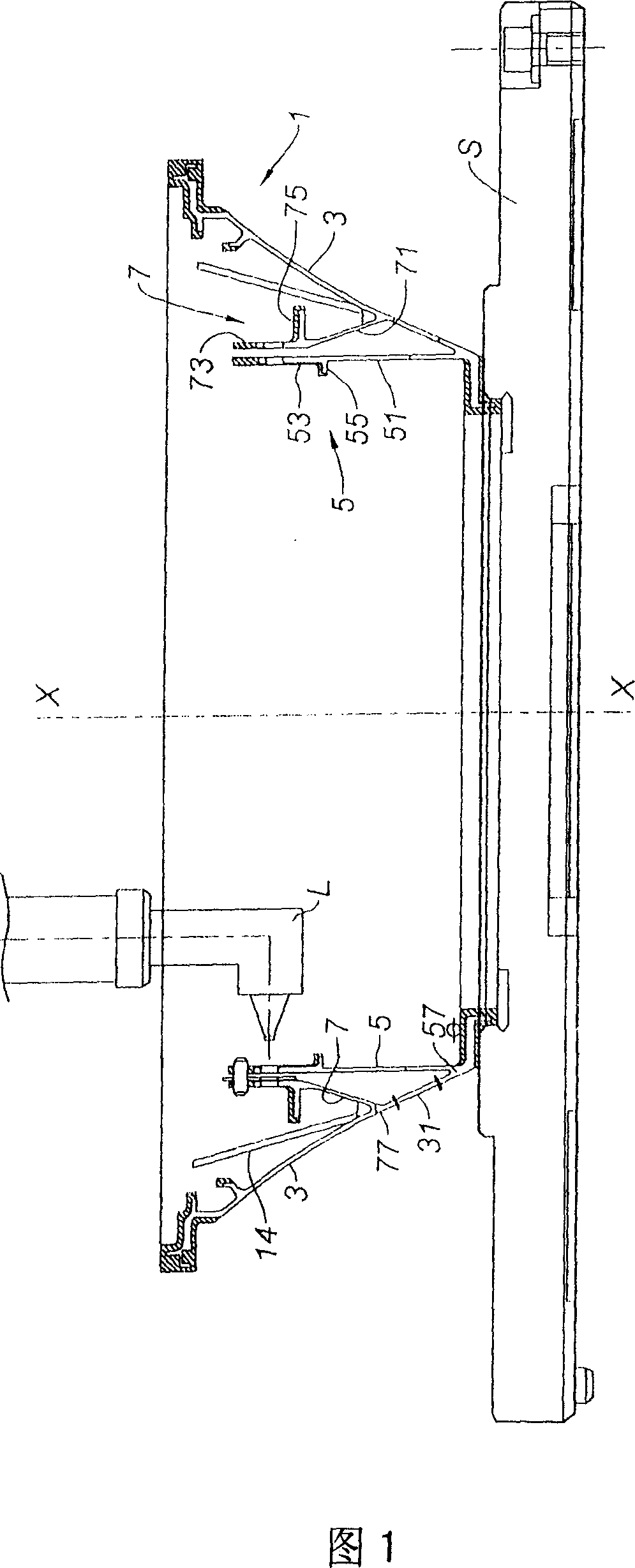

[0026] The invention is suitable for components of high pressure distributor housings of gas turbine engines. This is where the mount is placed downstream of the combustion chamber of the engine and consists of receiving the combustion gases coming out of the combustion chamber and directing them into the high pressure turbine wheel which is arranged axially downstream of the stage of distribution vanes which are arranged at their ends department. In FIG. 1 , the manufactured housing 1 is secured to a support S for various machining and assembly operations.

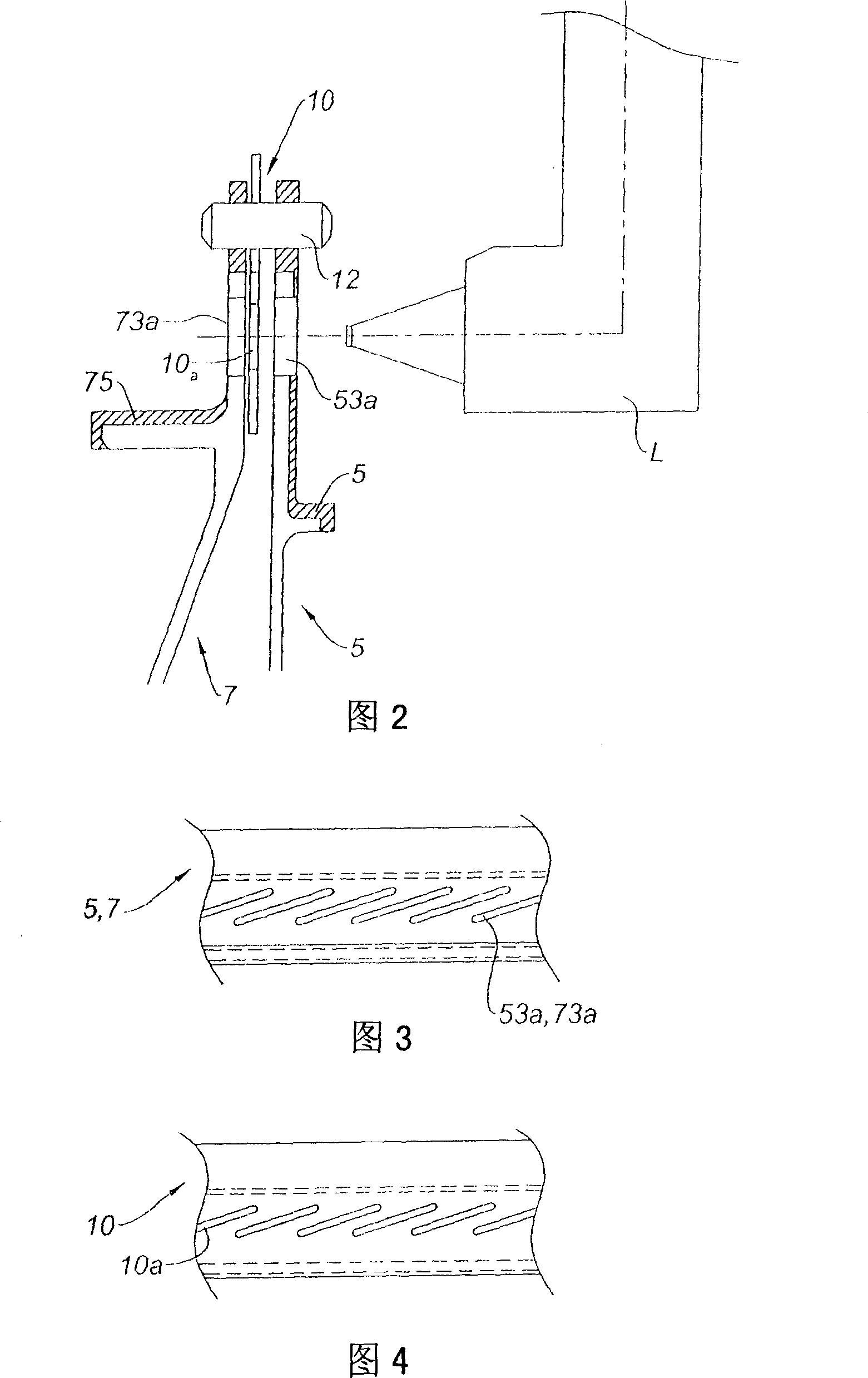

[0027] This casing comprises a common frusto-conical part 3 with axis xx. Various parts constituting the turbine stator are welded or machined on part 3 . In particular, this casing consists of two coaxial casings 5 and 7 between which there is an annular passage with axis xx for the combustion gases coming from the combustion chamber. This annular channel communicates on one side with a hole 31 cut in the wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com