Side lighting back light module

A backlight module, edge-lit technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of thermal coupling and interactive heat accumulation, and achieve the effect of increasing the divergence path and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

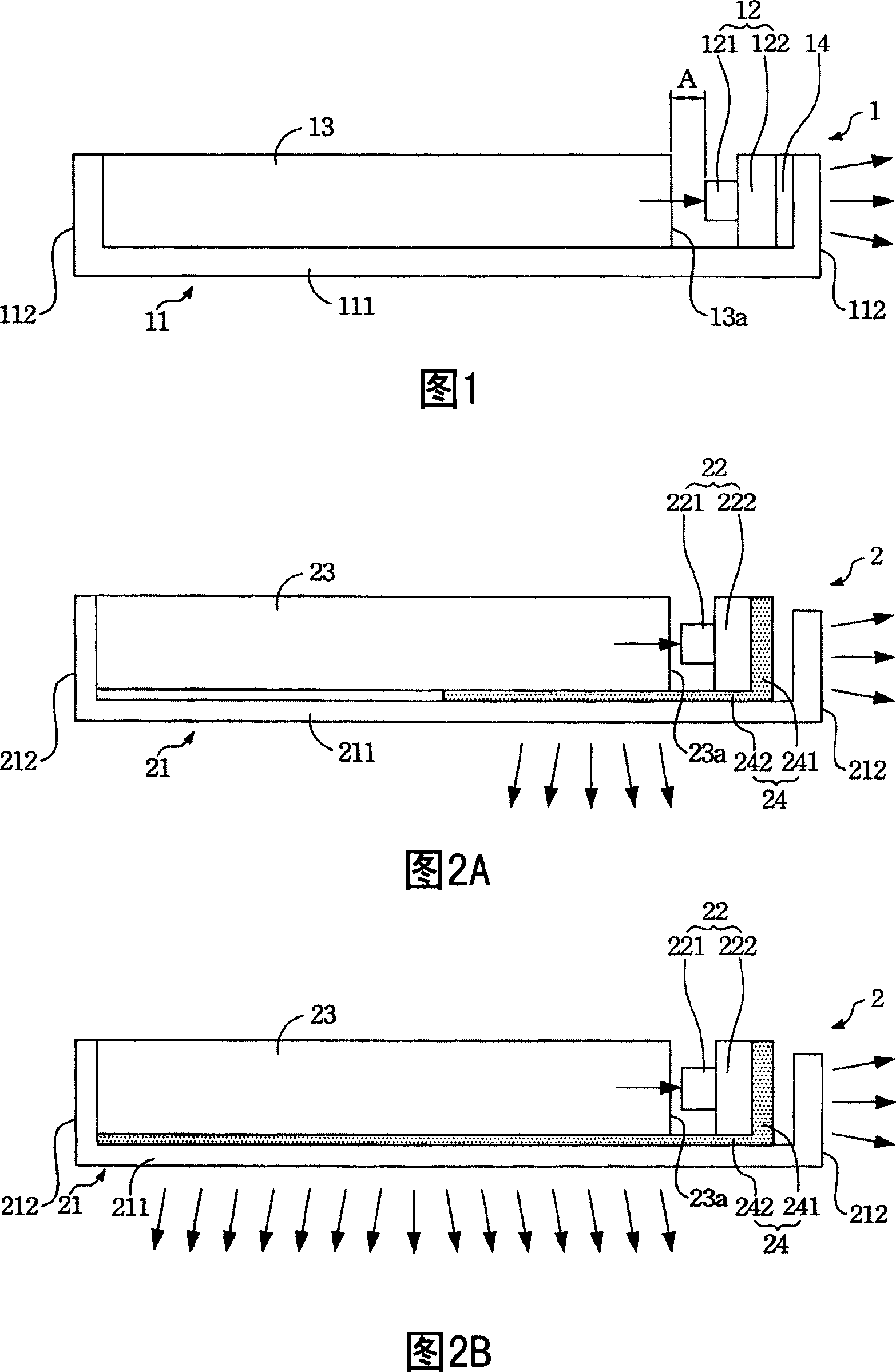

[0050]When the light guide plate 13 in Figure 1 is assembled into the backlight module 1, there is often a gap A between it and the LED 121. Close to LED 121 to provide higher light source utilization efficiency and avoid light leakage. However, the size design of the general frame always reserves some tolerance margins to match the actual processing or assembly tolerances; therefore, the existence of the gap A is difficult to avoid in actual situations. Therefore, in addition to the above-mentioned problem of poor heat dissipation, the known side-light LED backlight module also has the problem that the light incident efficiency needs to be improved.

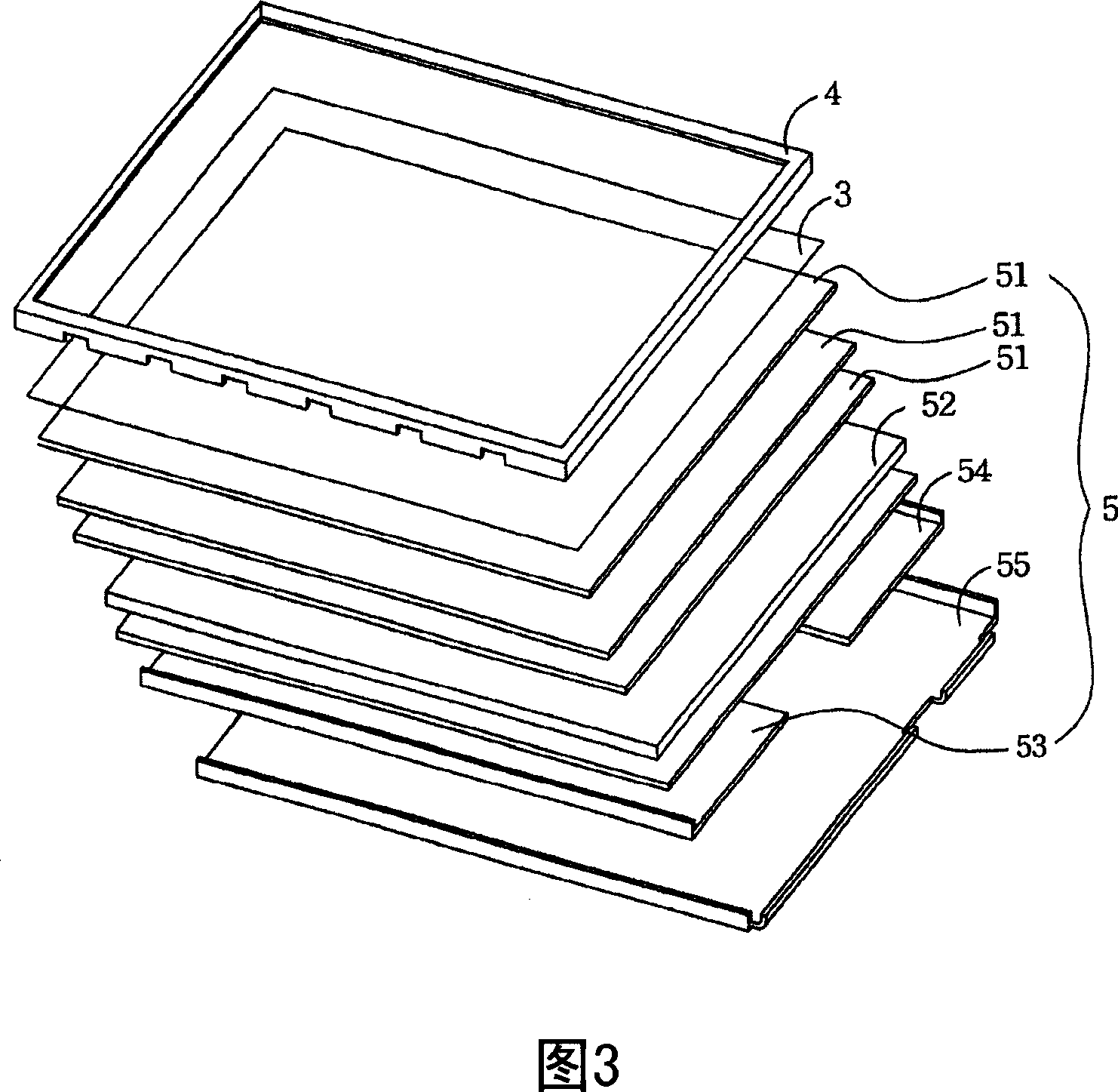

[0051] Please refer to FIG. 2A , which is a side sectional view of an edge type backlight module disclosed by the present invention in a preferred embodiment. The backlight module 2 includes a frame 21 , at least one LED light source group 22 , a light guide plate 23 and a heat conduction structure 24 . The frame 21 is a struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com