An installation device of the contactor

A technology for installing devices and contactors, applied in substation/switch layout details, electrical components, relay base/housing/cover, etc., can solve the problems of reduced strength, waste of materials, and increased volume of sliders, etc., to achieve installation and Simple and fast disassembly, stable and reliable performance, and the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

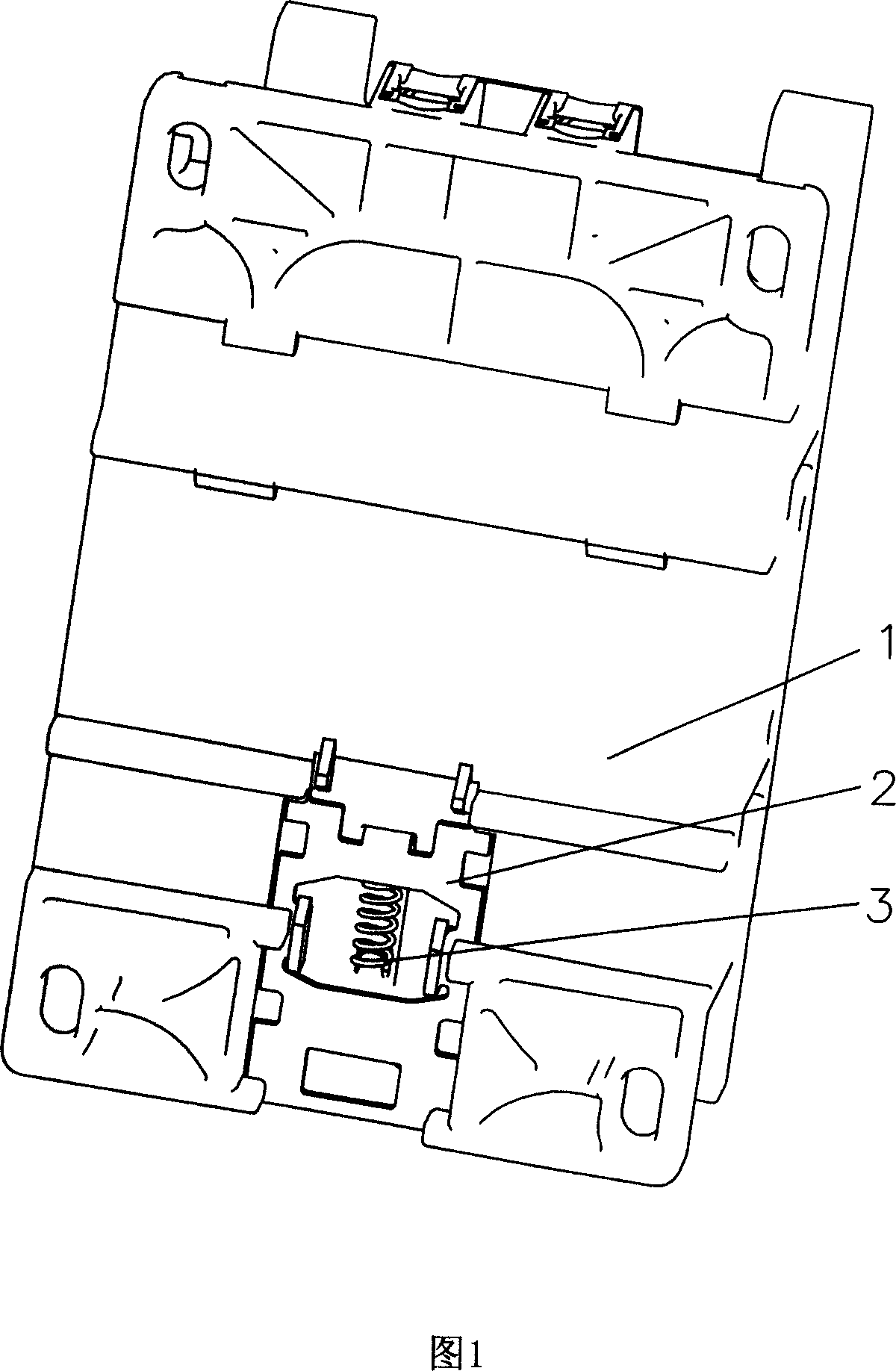

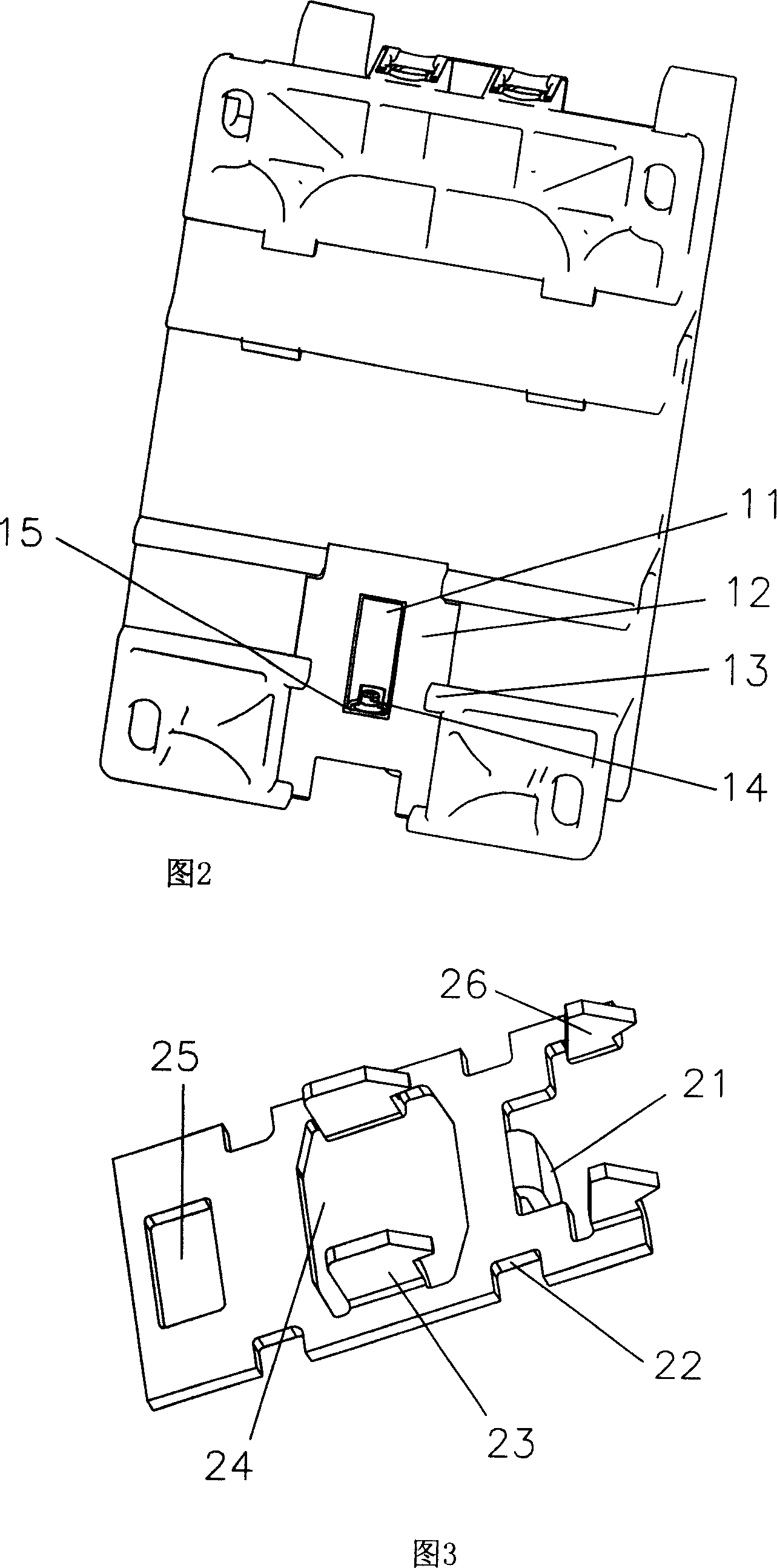

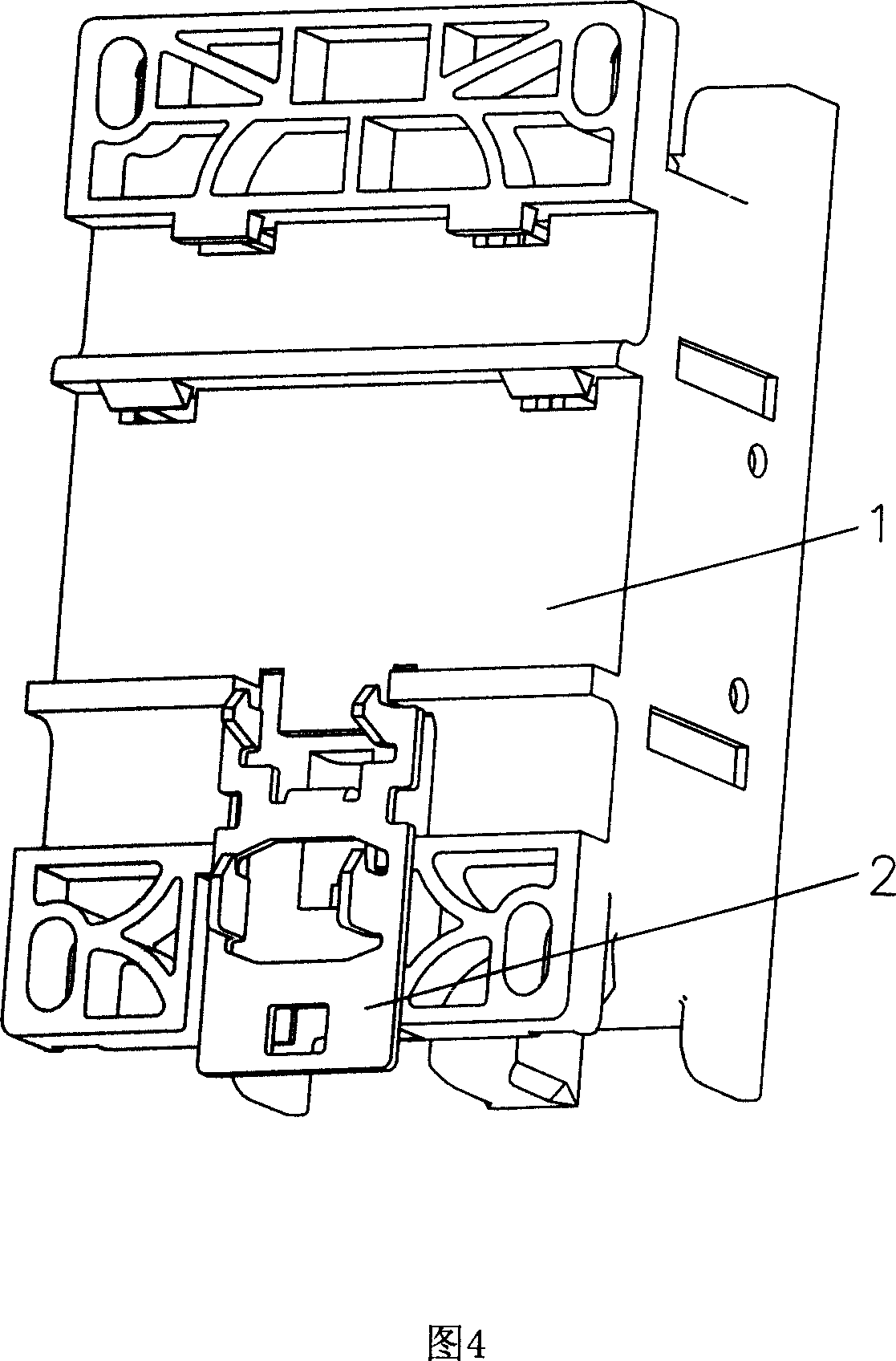

[0017] Referring to FIGS. 1-3 , the contactor installation device of the present invention includes a base 1 , a slider 2 and a compression spring 3 . The bottom surface of the base 1 has a mounting plane 12; the middle part of the mounting plane 12 is provided with a groove 11, and a pair of protrusions 13 are suspended above; the outer end 15 of the groove 11 is also provided with a boss 14 .

[0018] Two sides of the slider 2 are provided with a pair of notches 22 opposite to the protrusion 13 , an opening 24 opposite to the groove 11 is provided in the middle, and a limiting block 21 is provided at the inward end. The compression spring 3 is arranged in the groove 11 , one end is nested on the protruding column 14 , and the other end is pushed against the limit block 21 . The distance between the pair of protrusions 13 above the installation plane 12 and the installation plane 12 is equal to or slightly greater than the thickness of the slider 2 . The outer end of the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com