Brushless synchronization dynamotor

A technology of synchronous generator and main generator, applied in the direction of synchronous generator, etc., can solve the problems of inconvenient replacement and inspection of the rotating rectifier module, complicated drilling process of the shaft center, and complicated craftsmanship, so as to solve the problems of inconvenient replacement and inspection, Eliminate the effect of easy breakage and stable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

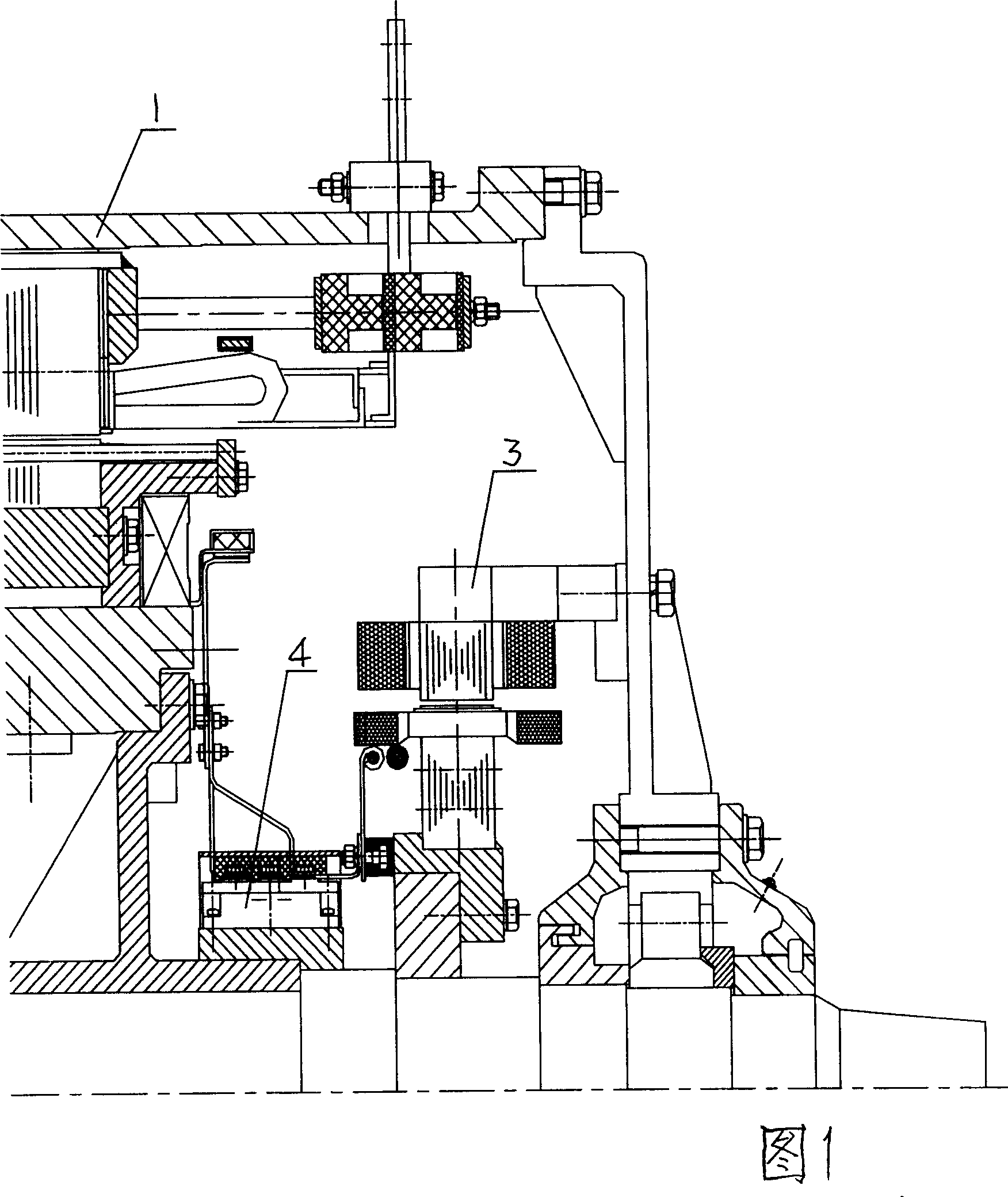

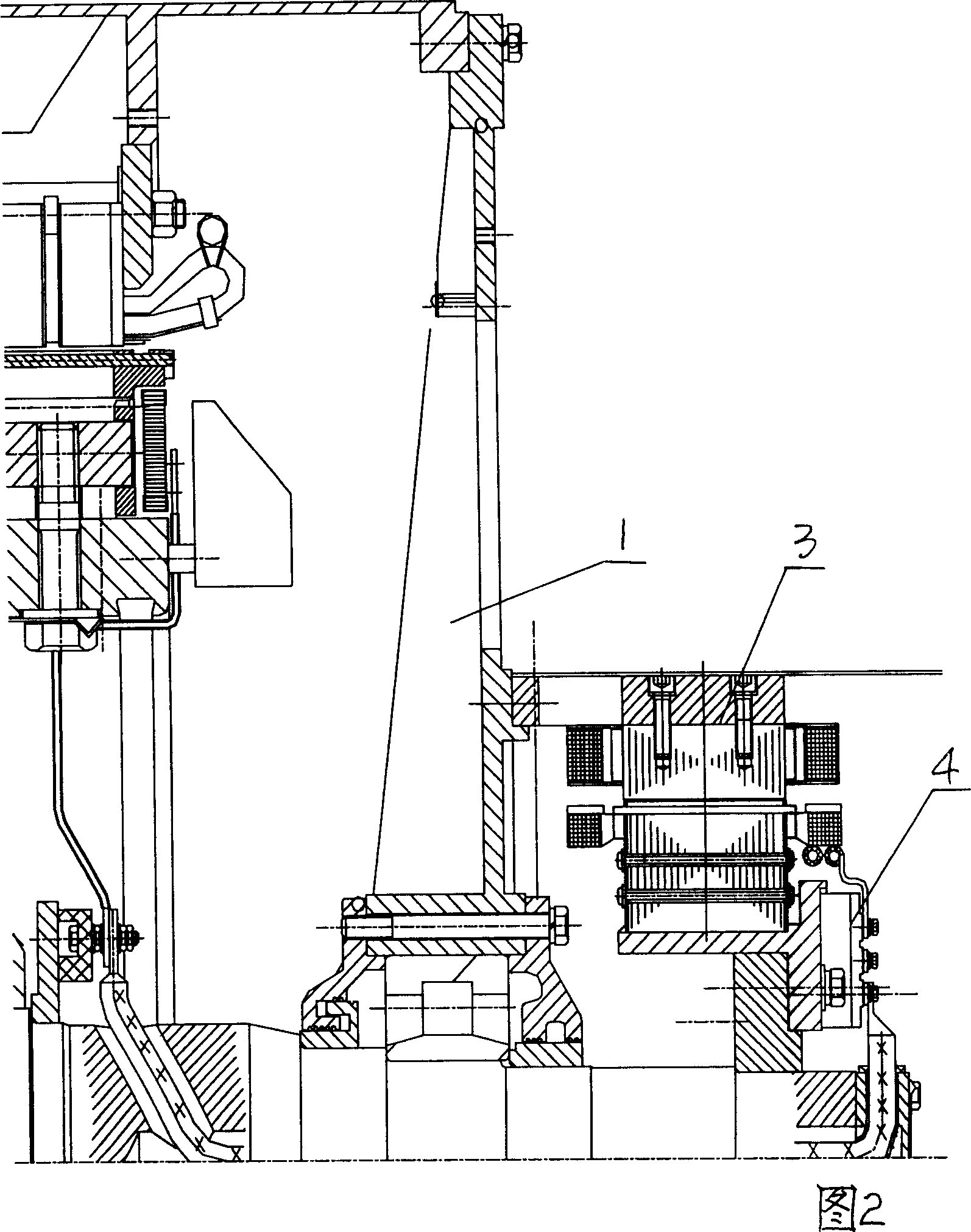

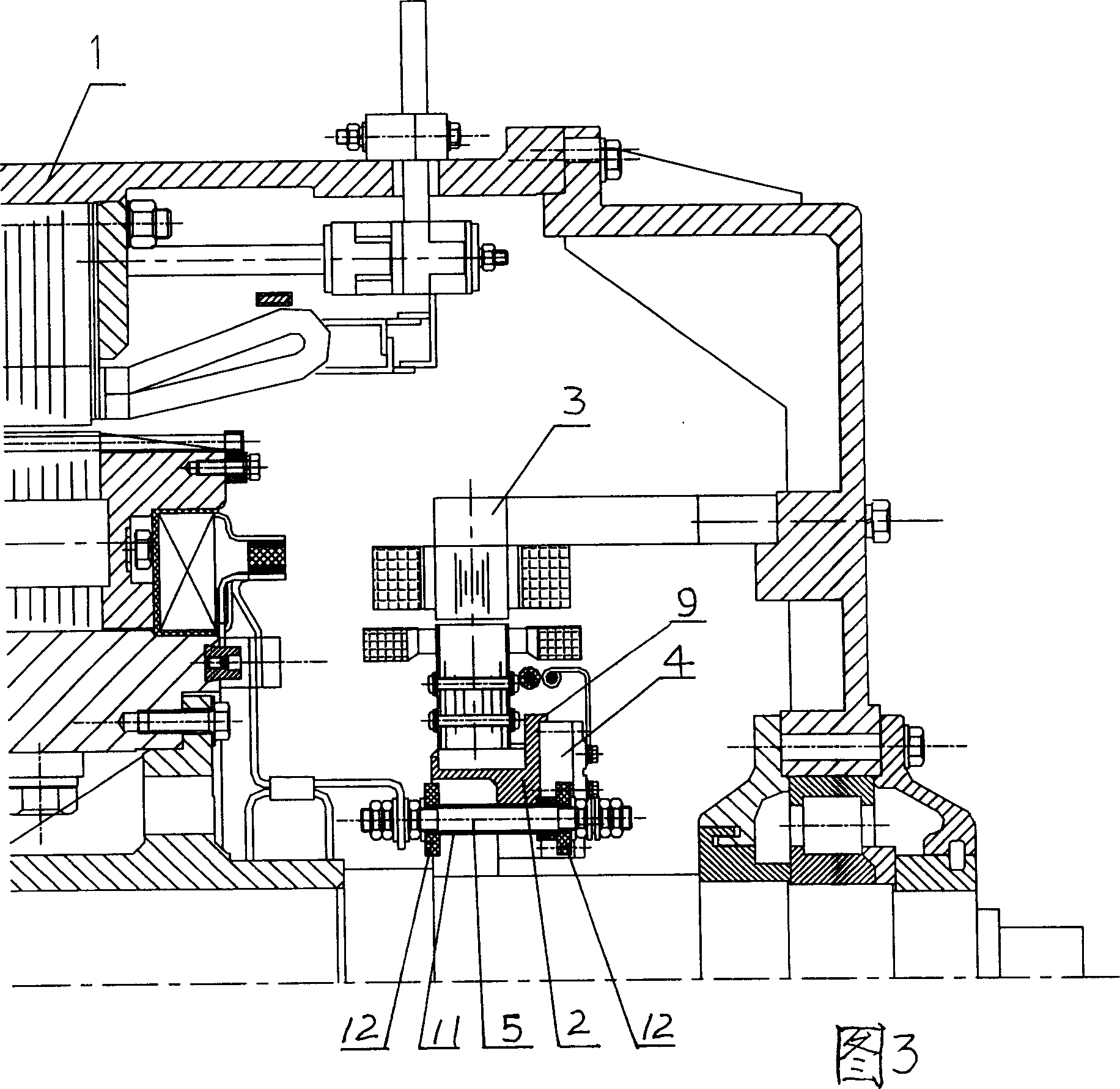

[0014] A brushless synchronous generator, including a main generator 1, a rectification device composed of a rectification module 4 and an exciter 3, a rotor bracket 2 is fixed on the rotor shaft inside the base of the main generator 1, and an exciter is fixed on the rotor bracket 2 For the rotor of machine 3, rectification module 4 of rectification device installed radially and vertically is fixed on the end face of rotor support 2 facing the air inlet of machine base end cover; the two output leads of rectification device composed of rectification module 4 are insulated Threaded copper rods 5 that pass through the rotor bracket and are processed at both ends. Like the existing brushless synchronous generator, the rotor bracket 2 is fixed on the bushing 6 on the rotor shaft, so the copper rod 5 passes through the bushing 6 while passing through the rotor bracket 2 . The copper rod 5 is sheathed with an insulating sleeve 11 and an insulating pad 12 to realize insulation passin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com