Method of detecting and controlling crane safety system

A detection control and safety system technology, applied in safety devices, load hanging components, transportation and packaging, etc., can solve problems such as unintuitive, reduce the reliability of crane safe operation, unfavorable operator observation and use, etc., to achieve precise control , fuel consumption is economical and reasonable, and the effect of high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The crane safety system detection and control method of the present invention will be described in detail below in conjunction with the embodiments.

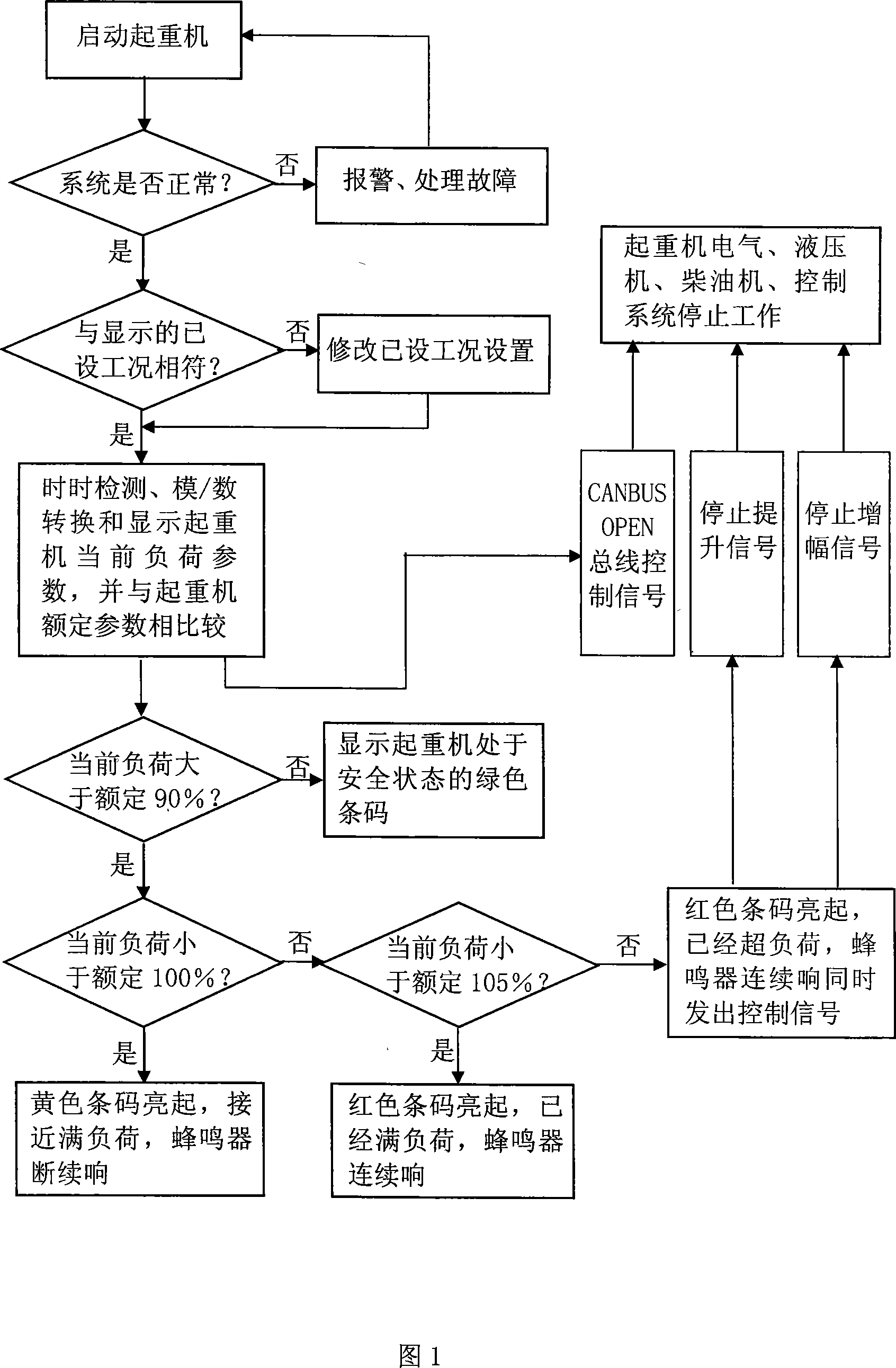

[0017] As shown in Figure 1, the crane safety system detection and control method of the present invention includes the following stages:

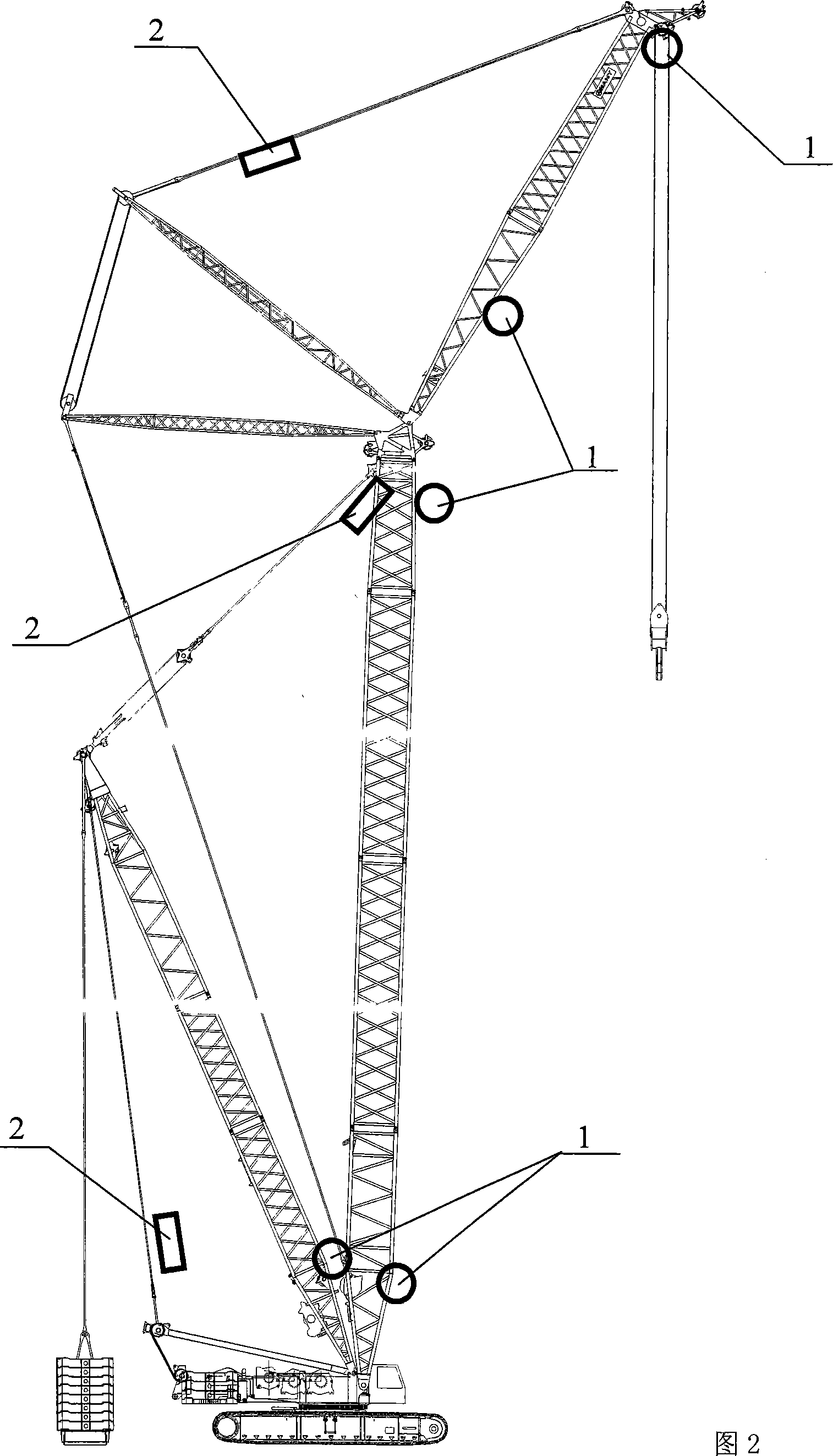

[0018] The stage of starting the crane and judging whether the system is normal: starting the crane S1; judging whether the system is normal S2, that is, checking whether the signal of the sensor in the system is normal. The setting of the sensor is shown in Figure 2, including the jib installed on the crane , the angle sensor 1 on the main arm and the super lifting mast and the tension sensor 2 arranged on each guy wire. When the system is normal, proceed to the next step; when the system is not normal, display the fault code, sound and light alarm, control the crane not to work, and deal with the fault S3, and then return to S1.

[0019] The stage of judging whether the currently s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com