Heat transfer tube and heat exchanger using same

A technology of heat exchangers and heat transfer tubes, applied in heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve problems such as high cost, difficult shape change, and inability to obtain heat transfer performance, and achieve improved The effect of heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0028] The structure of the heat transfer tube

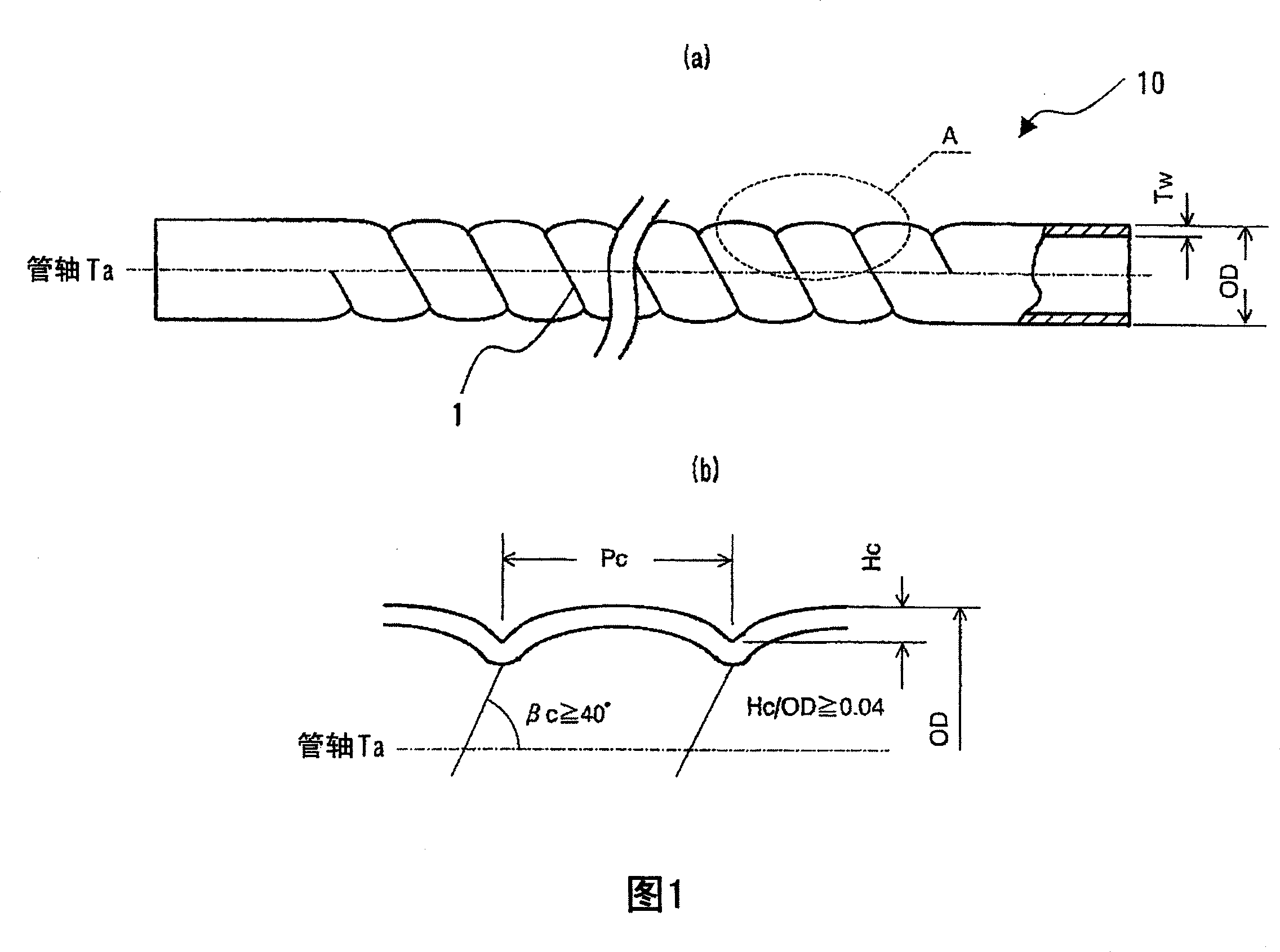

[0029] 1 is an explanatory view showing the structure of a heat transfer tube according to a first embodiment of the present invention, FIG. 1( a ) shows an overall view, and FIG. 1( b ) shows an enlarged cross-sectional view of a region A of FIG. 1( a ).

[0030] The heat transfer tube (corrugated heat transfer tube) 10 according to this embodiment is a processed corrugated tube used as a water tube constituting a heat exchanger (for example, a water-refrigerant heat exchanger for a heat pump water heater). That is, heat is exchanged between the water flowing inside the heat transfer tube 10 and the refrigerant flowing outside the heat transfer tube 10 . The so-called bellows refers to a tube that usually has a corrugated helical structure on the inside and outside.

[0031] The corrugated heat transfer tube 10 according to this embodiment is characterized in that when the corrugated groove depth of the corrugated shape is rep...

no. 2 approach

[0035] The structure of the heat transfer tube

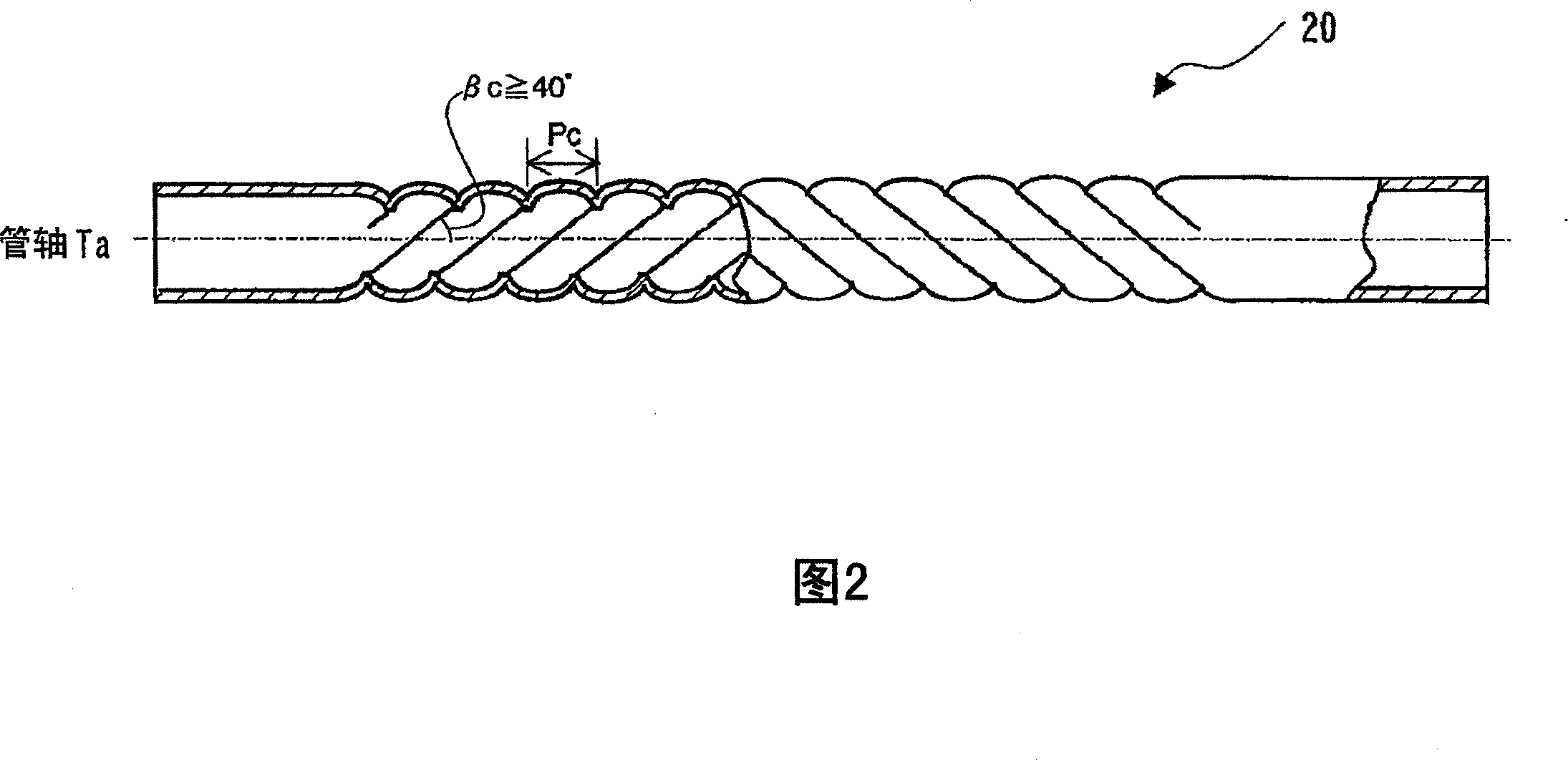

[0036] Fig. 2 is an explanatory view showing the structure of a heat transfer tube according to a second embodiment of the present invention.

[0037] Compared with the corrugated heat transfer tube 10 according to the first embodiment, which uses one processed corrugated tube, the corrugated tube 20 according to this embodiment uses three processed corrugated tubes, and is used as a water tube constituting a heat exchanger. If the number of strips increases, the advantage in cost also increases due to the increase in processing speed.

[0038] The twist angle βc tends to be smaller when processed with three pieces than with one piece. By reducing the interval between adjacent corrugated grooves 1, that is, the corrugated pitch Pc, it is possible to achieve a groove with an inner surface. High twist angles above 40° are difficult to manufacture in tubes.

[0039] Next, a heat exchanger including the above-mentioned corrugated ...

no. 3 approach

[0041] Structure of the heat exchanger

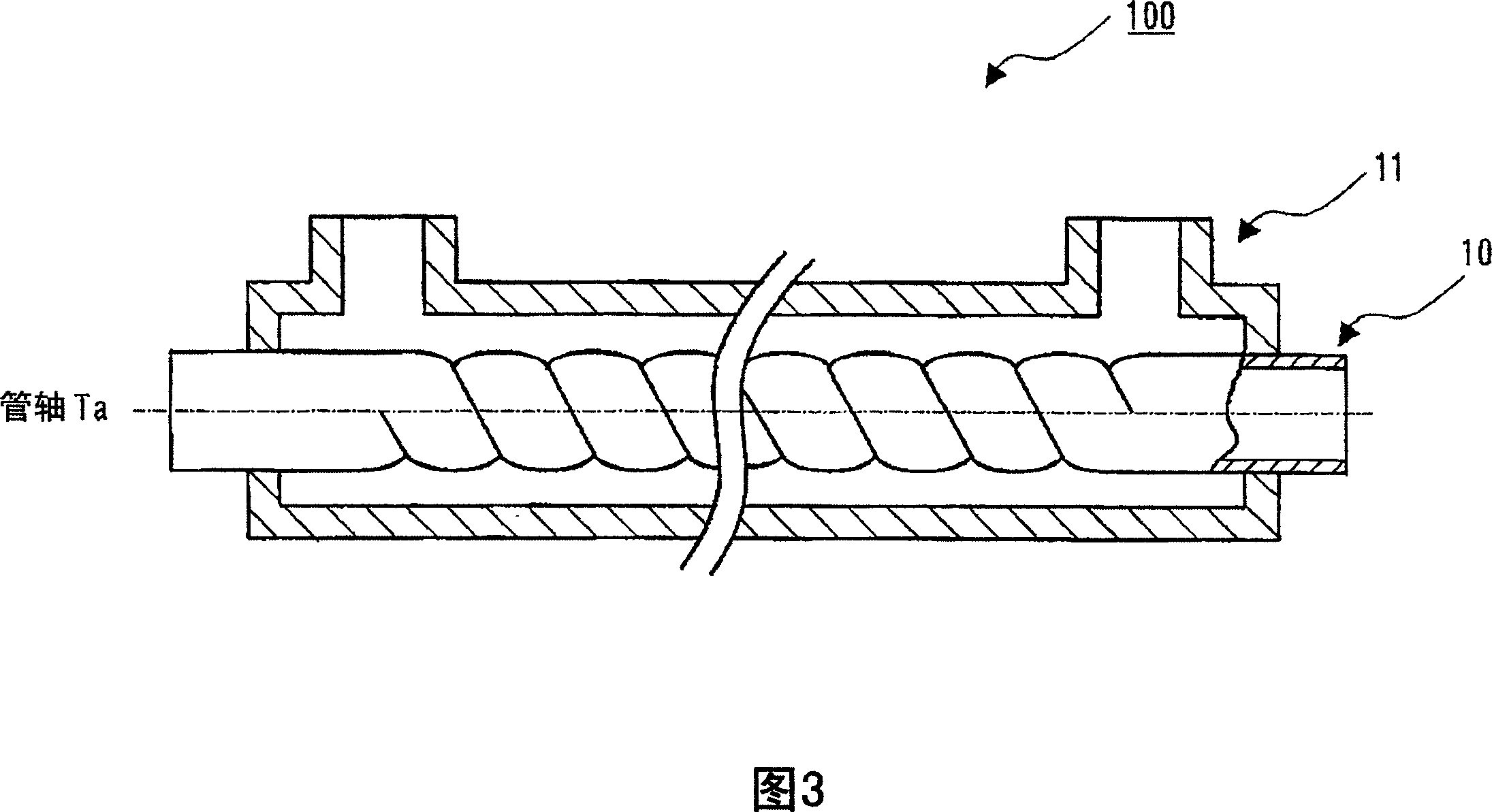

[0042] Fig. 3 is an explanatory diagram showing the structure of a heat exchanger according to a third embodiment of the present invention.

[0043] In the heat exchanger (double-pipe heat exchanger) 100 of this embodiment, the heat transfer tube (for example, the corrugated heat transfer tube 10) related to the above-mentioned embodiment of the present invention is used as an inner tube, and an outer tube 11 is provided on the outer side thereof. The annular passage between the heat transfer tube 10 and the outer tube 11 is formed by flowing refrigerant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com