Gradual damping oil buffer

A technology of buffer and damping oil, applied in contact vibration/shock damping, liquid shock absorber, high-voltage air circuit breaker, etc., can solve problems such as unreasonable distribution of braking force of oil buffer, achieve smooth return flow and fast speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

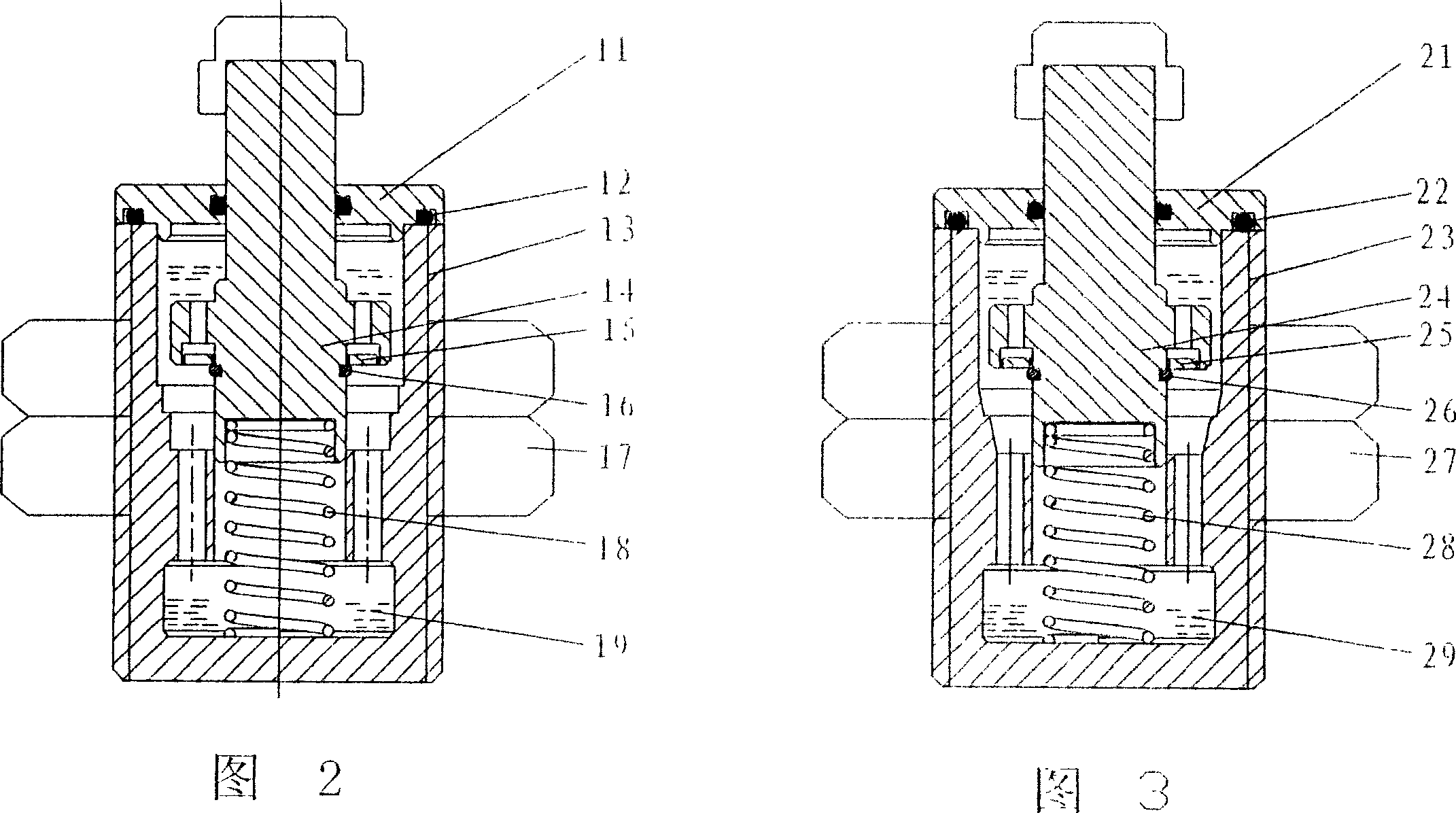

Embodiment 1

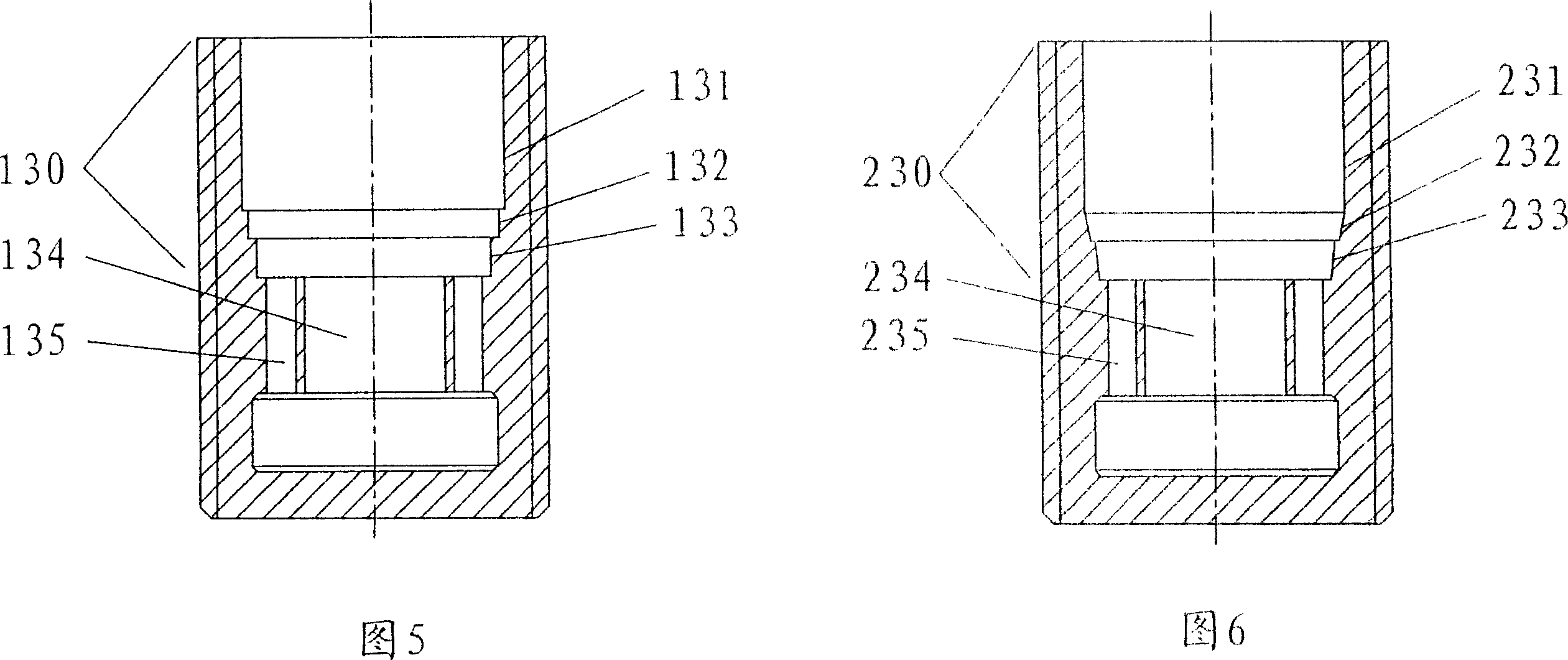

[0028] See Figure 2, Figure 4, Figure 5. In this embodiment, the oil buffer includes an end cover 11, a sealing ring 12, an oil cylinder 13, a piston 14, an annular stop ring 15, and a stopper 16 to form a piston assembly. The fixing nut 17 fixes the oil buffer on the vacuum circuit breaker, and the piston A stage clip 18 is connected to the bottom, and buffer oil 19 is filled in the oil cylinder; the end cover 11 and the sealing ring 12 seal the buffer oil in the cavity of the oil cylinder 13 .

[0029] There is a working area 130 and a guide hole 134 in the oil cylinder 13, wherein the inner wall of the working area 130 is composed of several sections of cylindrical surfaces 131, 132, 133, with rounded corners smoothly transitioning between each section. The inner diameter gradually becomes smaller; several oil holes 135 are distributed around the periphery of the guide hole 134 .

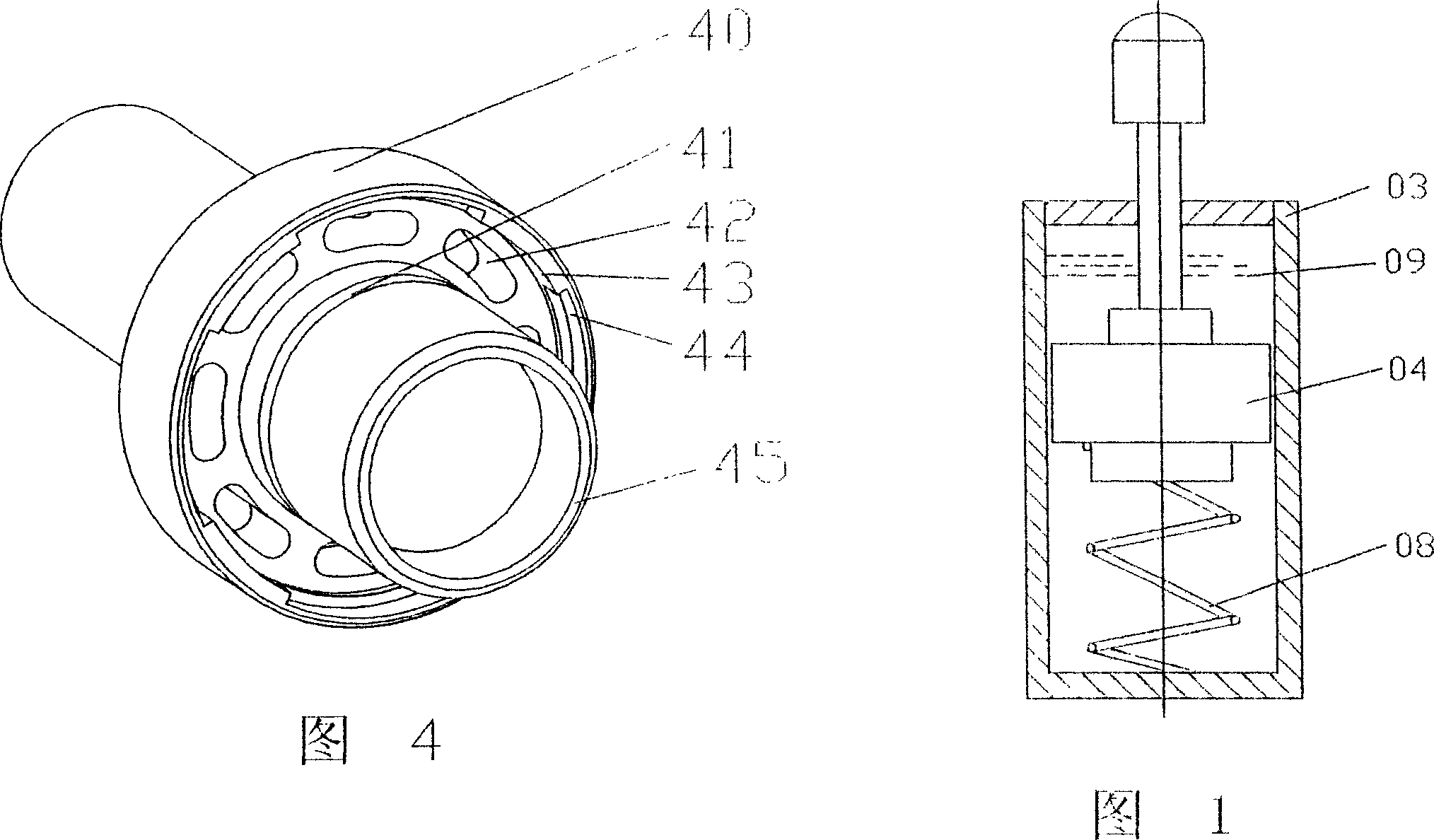

[0030] The piston 14 is a multi-section cylinder, the lower section is a guide cylinder 45, ...

Embodiment 2

[0033] See Figure 3, Figure 4, Figure 6. In this embodiment, the oil buffer includes an end cover 21, a sealing ring 22, an oil cylinder 23, a piston 24, an annular stop ring 25, and a stopper 26 to form a piston assembly. The fixing nut 27 fixes the oil buffer on the vacuum circuit breaker, and the piston The bottom is connected with stage clip 28, and buffer oil 29 is filled in the oil cylinder;

[0034] There is a working area 230 and a guide hole 234 in the oil cylinder 23. The inner wall of the working area 230 can also be divided into three sections 231, 232, and 233, wherein both sections 232 and 233 are in the shape of a truncated cone, and the inner diameter of the oil cylinder gradually decreases from top to bottom; A plurality of oil passing holes 235 are distributed around the periphery of the guide hole 234 .

[0035] The piston 24 is a multi-section cylinder, the lower section is a guide cylinder 45, and the middle section is a piston main body 40 (the piston in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com