Heat exchanger with indentation pattern

A technology of heat exchangers and heat exchange plates, which is applied in the direction of heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., and can solve problems such as high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Plate heat exchangers are well known devices for transferring heat between two different media. Plate heat exchangers are used in many different applications, and the invention is not limited to any particular application. The present invention is intended to apply to all brazed heat exchangers or heat exchangers assembled by other methods such as by welding, adhesives, or diffusion. The heat exchanger comprises a plate with an indented pattern and connections for the inlet and outlet of the two media. The plates are gathered in assemblies and joined together to form a complete device. The connection of the plates creates separate channels for the two media which circulate in countercurrent between the interleaved sets of plates. This technique is well known and thus will not be described in detail here.

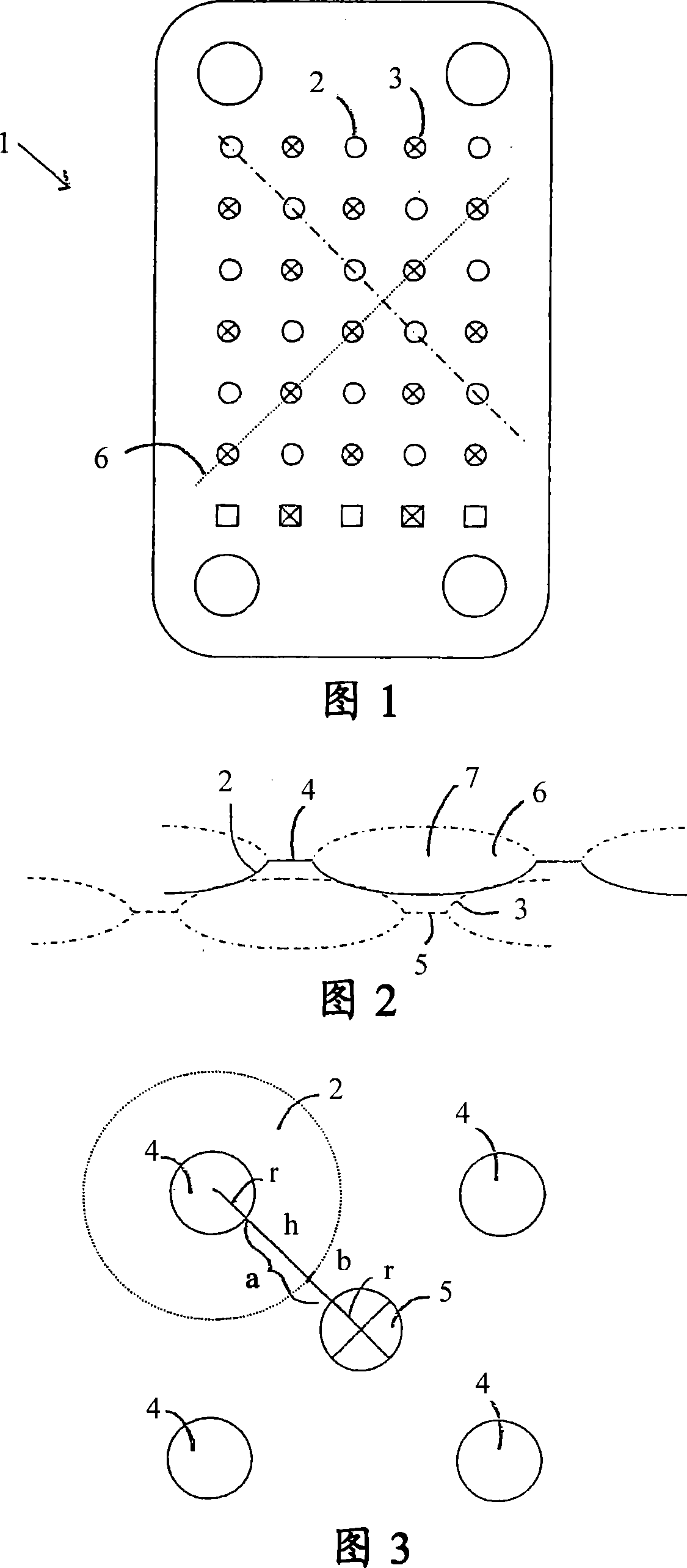

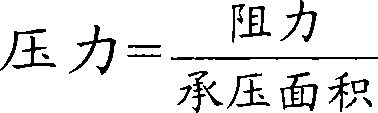

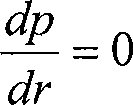

[0017] Fig. 1 is a plan view of an example of a heat exchange plate 1 according to the present invention. At the four corners are conventional connections for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com