Method for checking capsules

A technology of capsules and empty capsules, which is applied in the fields of capsule transportation, material check weighing, and pharmaceutical formulations, and can solve problems such as inability to obtain accurate information about the correctness of capsules, uneven weight of capsules, and incorrect dosage of medicines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

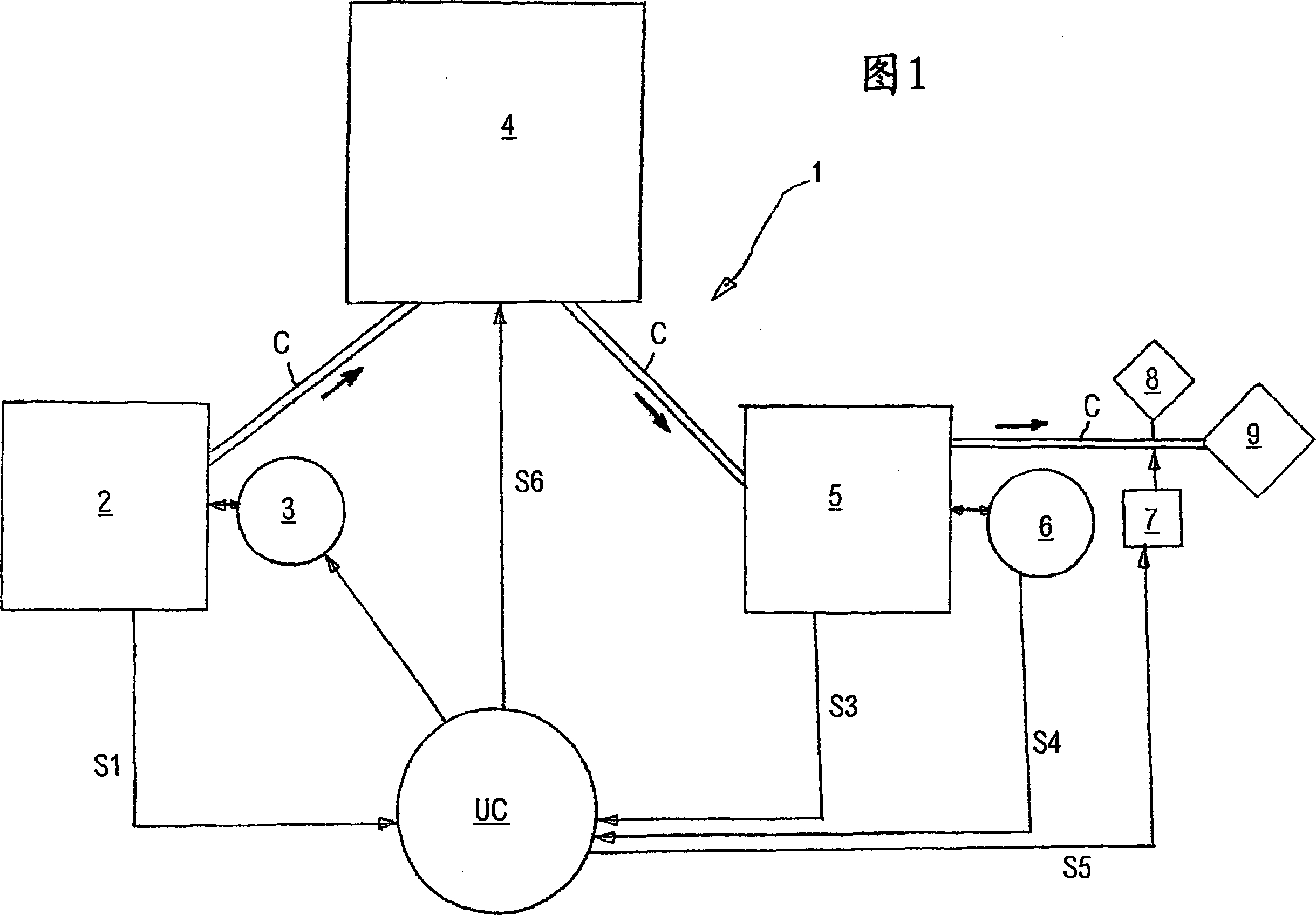

[0016] The plant 1 comprises a weighing device 2 adapted to detect and check the effective weight of each "empty closed capsule", where "empty closed capsule" refers to the hard plastic cap on which the associated also hard plastic Assemblies formed on the body.

[0017] The device 2 is preferably but not exclusively of the type disclosed and protected in European patent EP 886 765 B1 by the same applicant (the reader is referred to its disclosure and drawings, but not necessarily in detail), which essentially comprises a belt A tumbler with suction seats that picks up empty capsules from a hopper and then delivers them to a set of weighing stations, each of which is arranged in series and on which the capsules to be weighed are positioned Sensors, preferably load cell scales.

[0018] As already shown in this figure, the method of operation of the invention transmits the value of the weight of each empty closed capsule detected by the relevant scale of the device 2 to the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com